A kind of rotating glasses cleaning equipment and its cleaning basket

A cleaning equipment, a rotating technology, applied in the directions of glasses/protective glasses, glasses/goggles, cleaning methods and appliances, etc., can solve the problems of wearing the inner edge of the lens frame, affecting the viewing of movies, and high equipment costs, and reducing cleaning dead corners , Thoroughly clean the glasses, improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

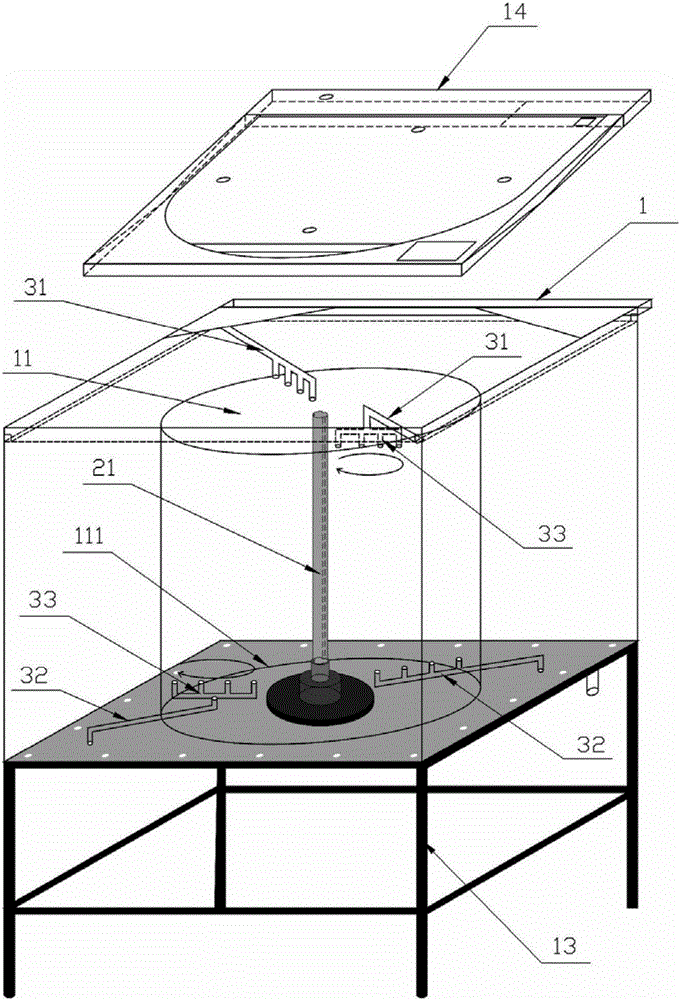

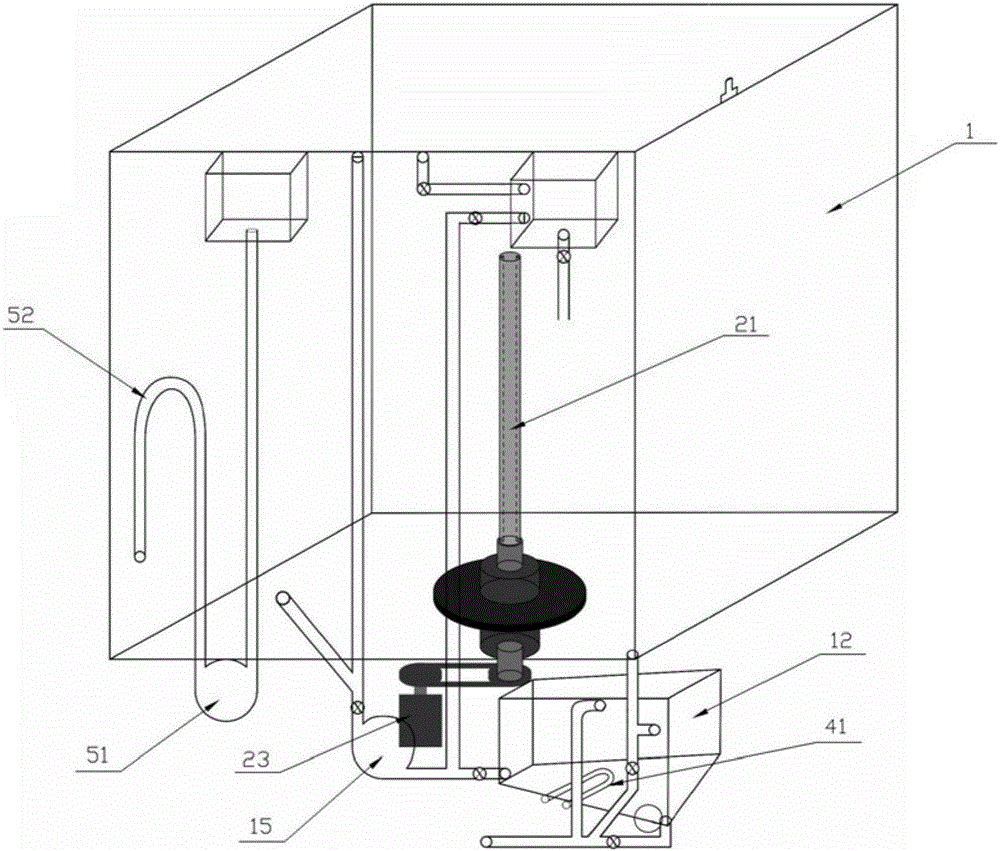

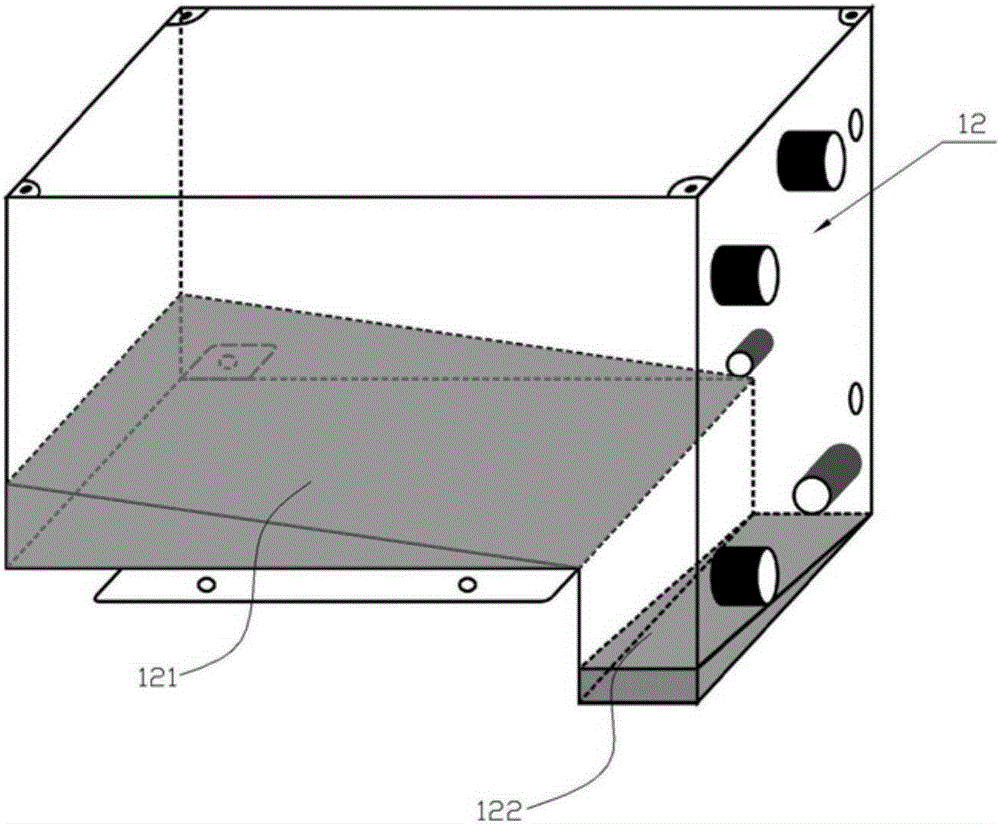

[0028] see Figure 1 to Figure 7 , a preferred embodiment of the present invention provides a kind of rotary glasses cleaning equipment, comprises cabinet 1, rotating basket device and spray device, and described cabinet 1 interior is provided with cleaning tank 11, and in this embodiment, this cabinet 1 Designed as a rectangle, the cleaning tank 11 is designed as a cylinder; the bottom of the cabinet 1 is provided with a water tank 12, the water tank 12 is externally connected to a water source, and an electric control valve is used to control the entry of the water source; the rotating basket device includes a driving device, a rotating shaft 21 and at least one cleaning basket 22, the rotating shaft 21 is rotatably installed on the vertical center line of the cleaning tank 11, and the bottom of the rotating shaft 21 is connected to the driving device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com