Planar needle roller thrust bearing with gaskets embedded into plastic retainer

A thrust needle roller bearing and cage technology, applied in the field of bearing processing and manufacturing, can solve the problems of loss of customers and enterprises, missing thrust gaskets, hidden dangers of bearing safety, etc. The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

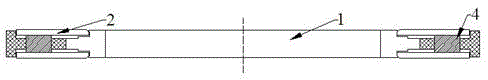

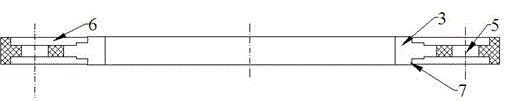

[0017] see Figure 1 to Figure 3 , the embodiment of the present invention includes: a gasket-embedded plastic cage type plane thrust needle roller bearing, including: a rolling element assembly 1 and two gaskets 2, the rolling element assembly 1 is the main work of the bearing mechanism.

[0018] The rolling element assembly 1 includes: a plastic cage 3 and a needle roller 4, the plastic cage 3 is circular, the plastic cage 3 is used to keep the rolling elements separated, and the bearing keeps the rolling elements during operation Evenly distributed along the bearing circumference, and guide the rolling elements to roll on the correct rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heart hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com