Elevator automatic spot inspection system

A spot inspection system and spot inspection technology, applied in elevators, transportation and packaging, etc., can solve the problems of low collection efficiency of spot inspection results and take a long time, and achieve the effect of ensuring service and efficiently collecting data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, examples are given, and the automatic inspection system for elevators according to the present invention will be described in detail with reference to the drawings.

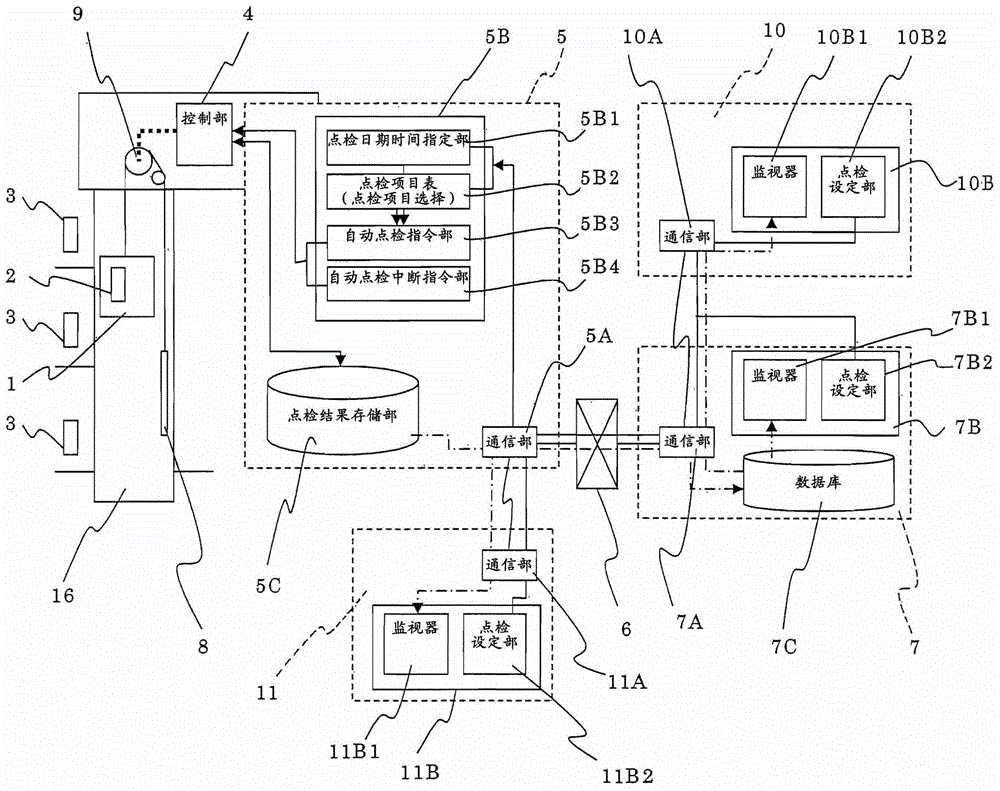

[0057] figure 1 It is a schematic block diagram showing the basic configuration of the automatic inspection system for elevators according to Embodiment 1 of the present invention. This automatic inspection system for elevators is configured such that the monitoring device 5 connected to the control unit (elevator control unit) 4 that controls the operation of the car 1 not only monitors the operating status of the elevator through the control unit 4, but also automatically implements the inspection through the control unit 4. In addition to the basic functions of inspection and inspection of the elevator, the monitoring device 5 communicates with a plurality of terminal devices (here indicates the management and control system described later) via a communication unit (here, the structure inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com