Apparatus for rounding hollow cylindrical workpieces

A hollow cylindrical, workpiece technology, applied in the field of the first workpiece, can solve the problems of operation cost, damage to the shell wall, formation of depressions, etc., and achieve the effect of simple and accurate setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

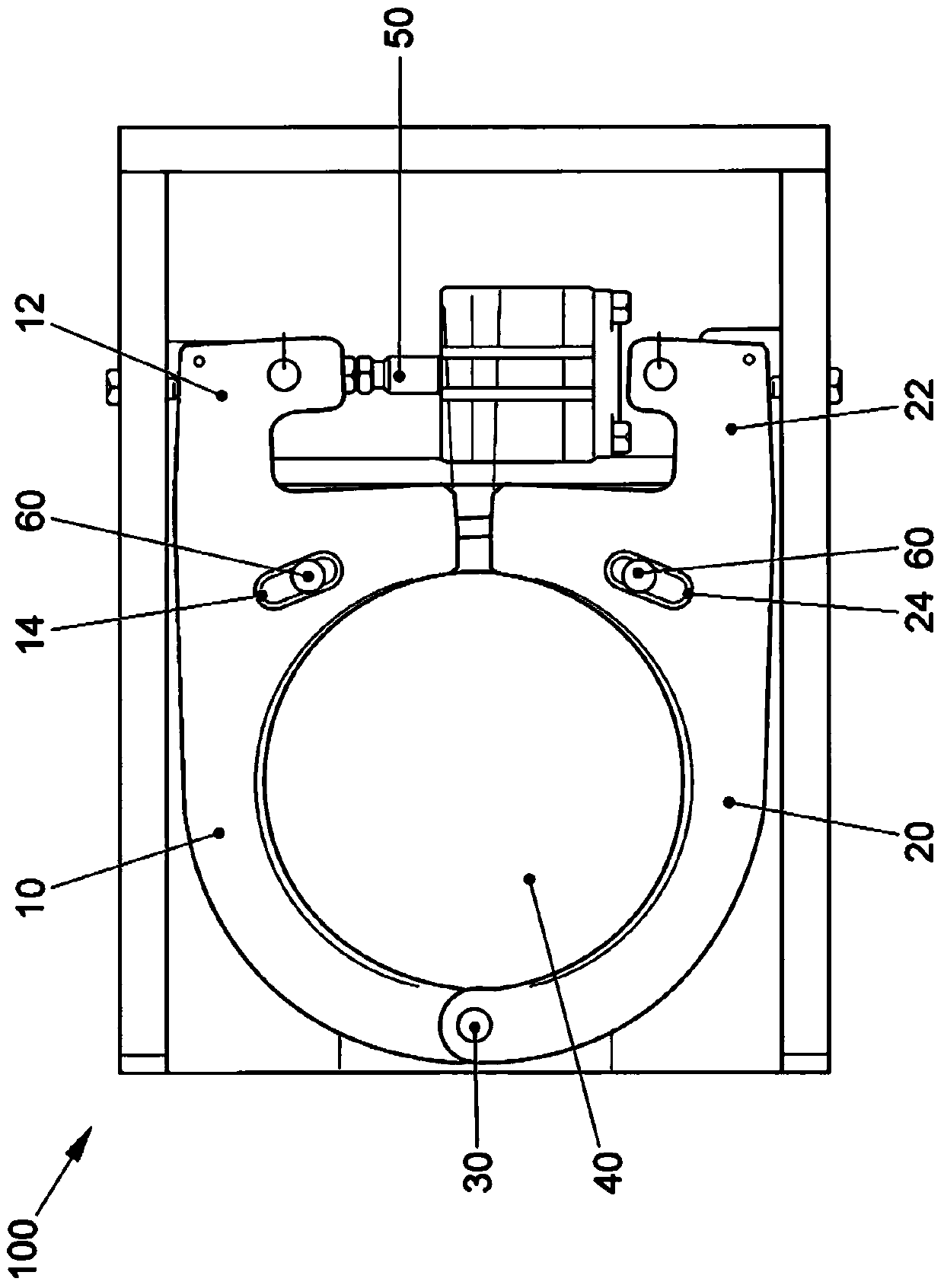

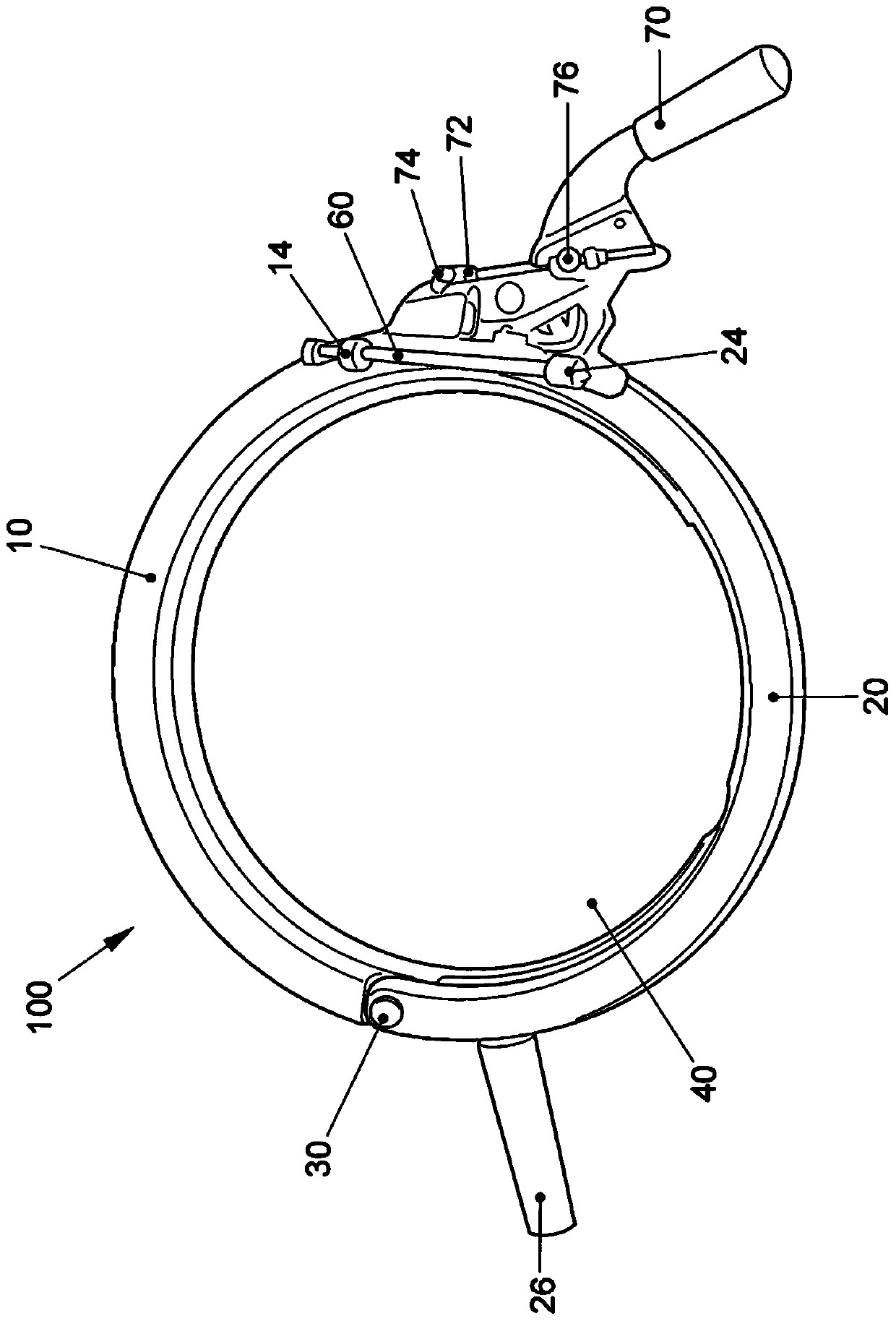

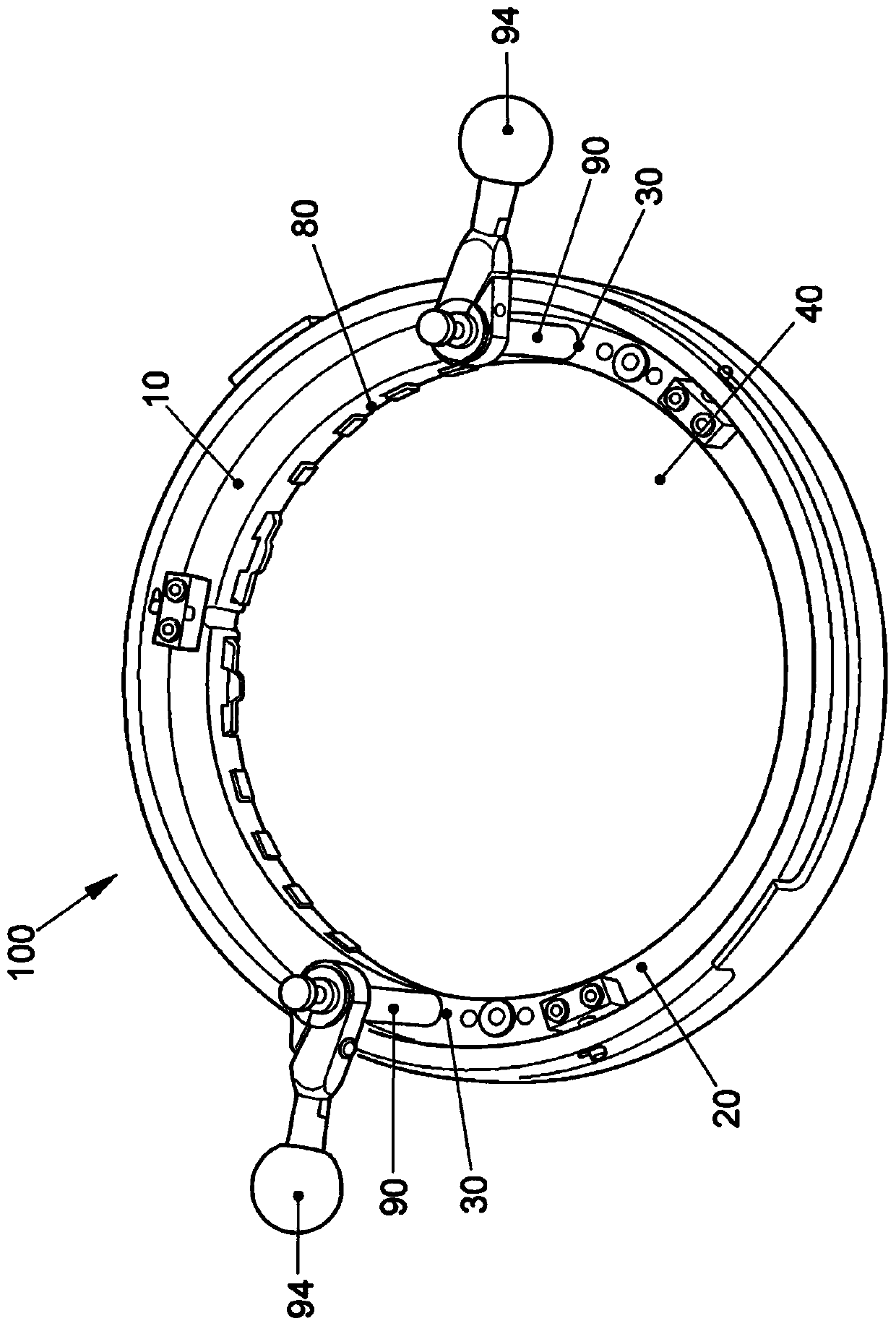

[0023] figure 1 An embodiment of the rounding tool 100 according to the invention is shown which corresponds to the second basic variant described above. The described embodiment consists of a first circular ring part 10 and a second circular ring part 20 , which are articulated to one another by means of their ends at articulation points 30 . The ring parts 10 , 20 jointly surround an approximately circular central opening 40 . exist figure 1 In the position of the ring segments 10, 20 shown, the circular shape of the central hole 40 is not perfect. In contrast, the central opening 40 here has a slightly widened shape. The relative rotation of the free ends of the ring parts 10 , 20 leads to a perfectly circular shape of the central opening 40 . Hence in figure 1 The hollow-cylindrical workpiece, not shown, in particular the housing of the multi-clutch unit, is rounded so that the essentially disc-shaped elements, in particular the transmission discs of the multi-clutch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com