Detachable roller of high pressure roller mill

A high-pressure roller mill and detachable connection technology, which is applied in grain processing and other directions, can solve the problems of affecting production efficiency, increasing production cost, and low metal utilization rate, so as to reduce production cost, facilitate maintenance, and prolong service life Effect

Inactive Publication Date: 2014-07-09

江苏恒业机械有限公司

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The rollers of traditional roller mills are manufactured by stacking wear-resistant welding rods or inlaid cast nails on the surface of the whole rotor. After the surface of this kind of roller is worn and damaged, it needs to be replaced together with the internal rotor as a whole. Replacing the whole roller not only affects the production efficiency, but also increases the production efficiency. Lower production costs, low metal utilization, resulting in a sharp increase in production costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

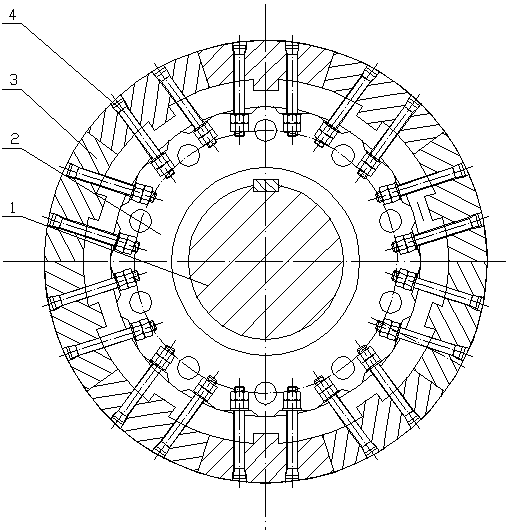

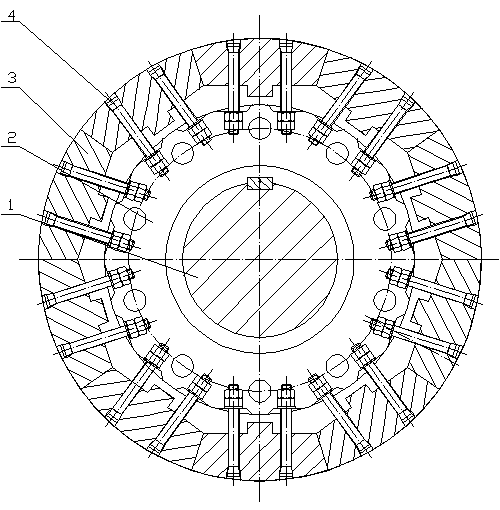

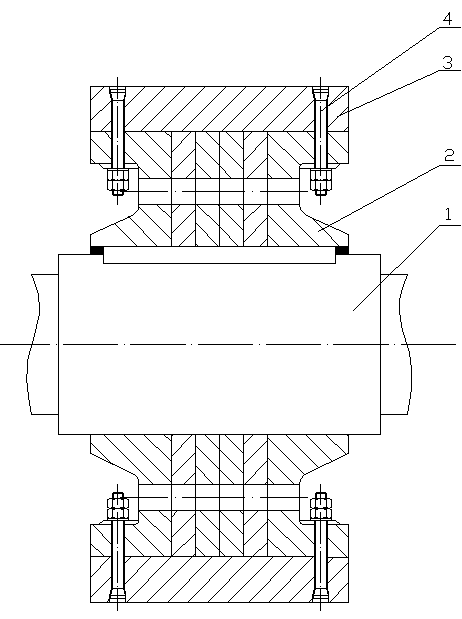

[0011] like figure 1 As shown in -3, the present invention includes a main shaft 1, a roll frame 2 and a wear-resistant roller skin 3, and the wear-resistant roller skin 3 is composed of several equal parts of small pieces of roller skins, and the wear-resistant roller skins are evenly distributed and of the same size. The small pieces of roll skin are detachably connected to the roll frame 2 through bolts 4 respectively.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A detachable roller of a high pressure roller mill relates to the technical field of structures of the detachable roller of the high pressure roller mill. The detachable roller comprises a main shaft, a roller rack and a wear resistant roller skin, the wear resistant roller skin is obtained by combining a plurality of small roller skins, the wear resistant roller skin is uniformly distributed, the small roller skins have a same size, and the small roller skins are detachably connected with the roller rack through bolts respectively. The wear resistant roller skin is divided into the plurality of independent and detachable small roller skins, so the wear resistant roller skin can be conveniently maintained; and the middle roller rack and the main shaft can be reused multiple times, so the service life of the roller is effectively prolonged, and the production cost is reduced.

Description

technical field [0001] The invention relates to the structural technical field of a detachable roller of a high-pressure roller mill. Background technique [0002] Usually, the high-pressure roller mill is used in the ultra-fine particle crushing industry. It mainly uses the high pressure of hydraulic energy storage to squeeze and crush the material through the relative rotation of the driving and driven rollers to complete the crushing process of the material. The rollers of traditional roller mills are manufactured by stacking wear-resistant welding rods or inlaid casting nails on the surface of the whole rotor. After the surface of this kind of roller is worn and damaged, it needs to be replaced together with the internal rotor as a whole. Replacing the whole roller not only affects the production efficiency, but also increases the production efficiency. Lower production costs, low metal utilization, resulting in a sharp increase in production costs. Contents of the inv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B02C4/30

Inventor 冯秀琴

Owner 江苏恒业机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com