A high-efficiency vacuum fryer and its control method

A vacuum fryer, high-efficiency technology, applied in electrical program control, program control in sequence/logic controller, oil/fat baking, etc., can solve the problem of rancidity and deterioration of frying oil, affecting consumers' health, and fat thickening And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

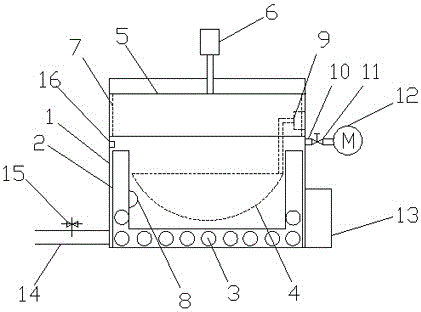

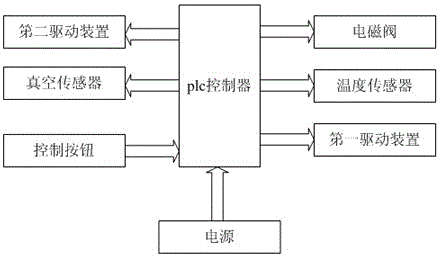

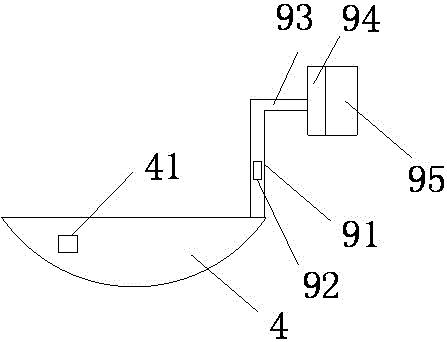

[0034] A kind of high-efficiency vacuum fryer, with reference to figure 1 , which includes a pot outer body 1, an inner pot 2 and a material pot 4, the pot outer body 1 is a sealed box, the inner pot 2 is arranged in the pot outer body 1, and the inner pot 2 is provided with a steam heating pipe 3, One side of the pot outer body 1 is provided with a steam inlet pipe 14, and the steam inlet pipe 14 is connected with the air inlet of the steam heating pipe 3, and the steam inlet pipe 14 is provided with a solenoid valve 15; the inner wall of the inner pot 2 is provided with a temperature sensor 8; The pot 4 is arranged in the inner pot 2, and the material pot 4 is hole-shaped; the inner wall of the pot outer body 1 on one side of the material pot 4 is provided with a first driving device 9, and the first driving device 9 is connected by a driving arm. One side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com