Nail gun

A nail gun and nail-shooting technology, applied in the field of nail guns, can solve problems such as the inability to maintain the temporary state of the work object, the inability to achieve a high degree of automation, and the reduction of product qualification rate, so as to achieve stable motion, easy control, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

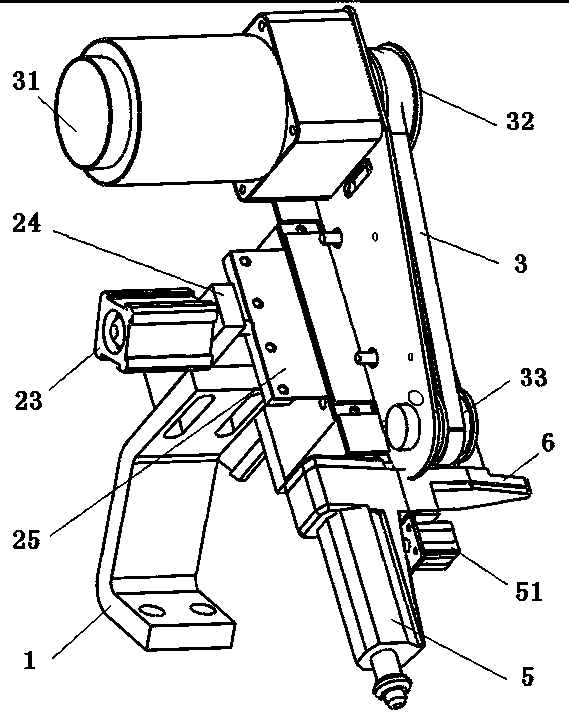

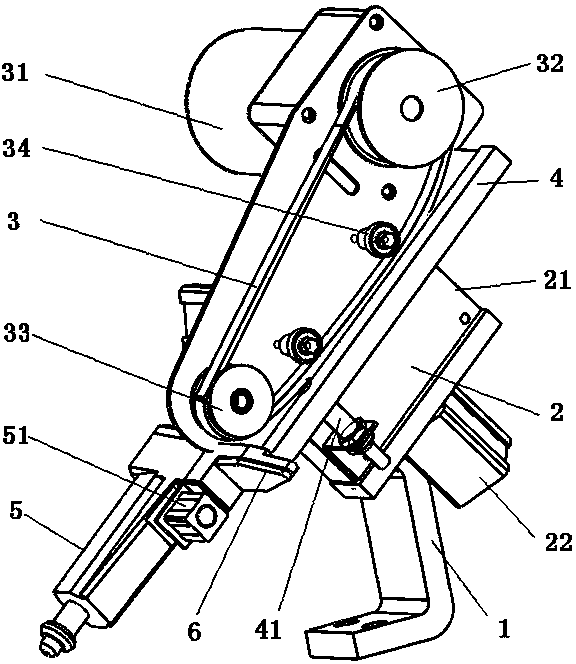

[0029] nail gun, such as Figure 1~2 As shown, it includes a machine base 1, a gun casing, a power part, a nail-shooting end, a nail-feeding part, and a control part. The machine base 1 is connected to the middle part of the nail-feeding part, and the nail-feeding part is connected to the nail-shooting end and the gun casing obliquely downward in turn, and the angle between the connecting line of the nail-feeding part, the nail-shooting end, and the gun shell and the horizontal plane is an acute angle.

[0030] In this embodiment, the machine base 1 is formed by bending a long steel plate, and is respectively arranged as a fixing seat, a support and a connecting end from bottom to top. A number of bolt holes are arranged on the fixing base, and the machine base 1 is fixed to the application equipment through bolts. The support is a section of folded pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com