Continuous phase plate machining error identification method

A processing error and phase plate technology, which is applied in the field of continuous phase plate processing error identification, can solve the problems of low matching probability, large amount of calculation, and failure to meet the requirements of CPP high-precision identification, and achieve comprehensive search, low dependence, and The effect of large pan detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

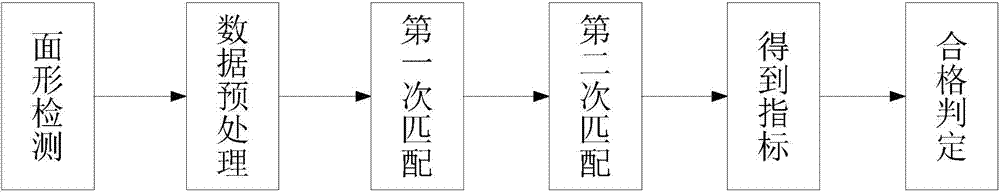

[0032] Such as figure 1 As shown, the process steps of the continuous phase plate processing error identification method provided by the present invention are as follows:

[0033] (1) Surface shape detection, using an interferometer and a translation stage to obtain the two-dimensional image data of the reference surface shape of the measured continuous phase plate (CPP) and the measured surface shape. In this embodiment, the width of the light-transmitting area of the measured element is 400mm, height 400mm, PV=2.3 wavelength, interferometer wavelength 632.8nm, optical path coefficient 0.5, interferometer image sensor pixel size 0.165mm, obtained image width is 2411 pixels, image height is 2411 pixels, image The number of effective points is 5812921 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com