Method and device for testing heat dissipation performance of radiator assembly

A heat dissipation performance and heat sink technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as inaccurate heat dissipation performance parameters, achieve the effects of shortening the development cycle, improving accuracy, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

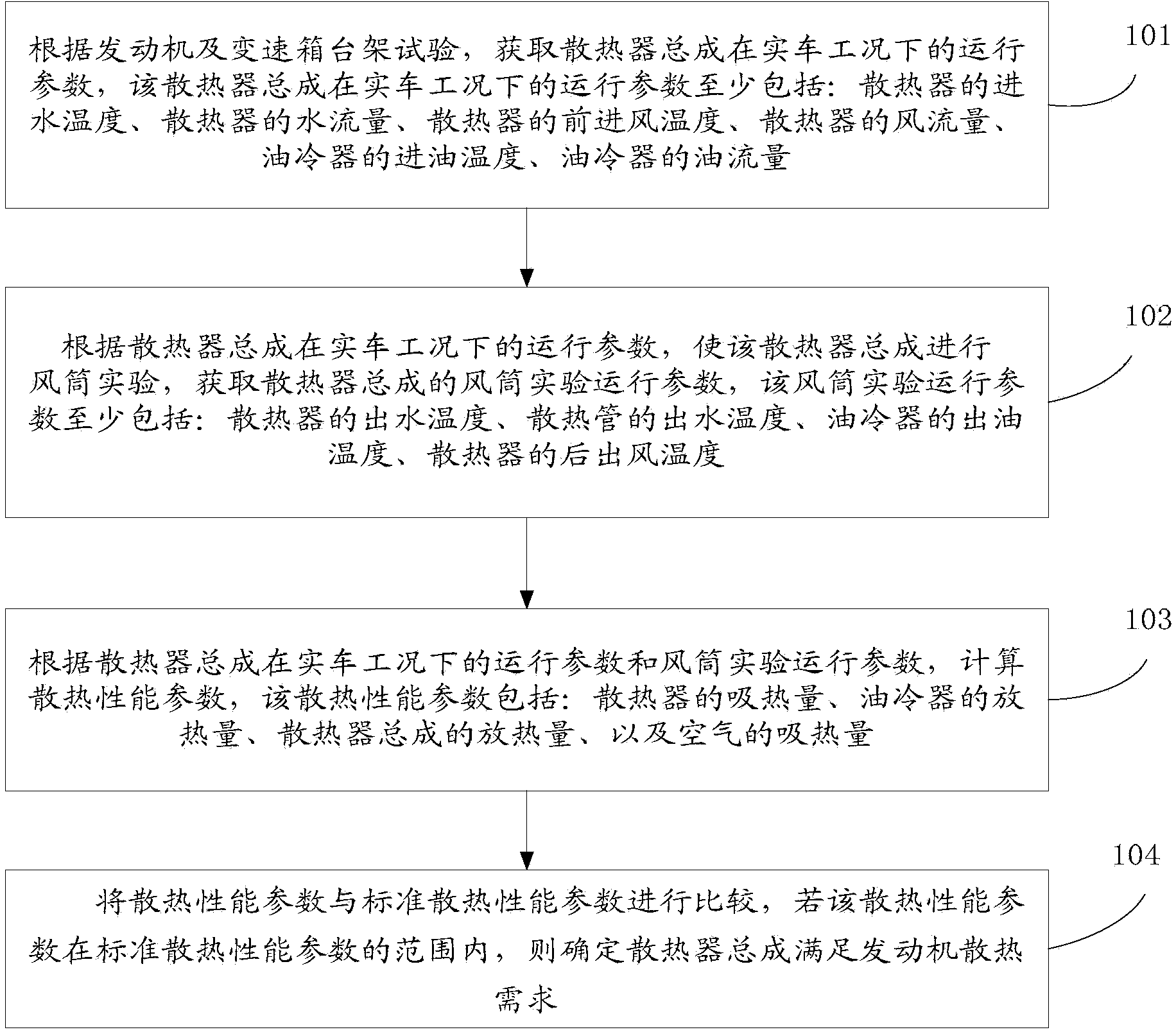

[0075] as attached figure 1 As shown, the embodiment of the present invention provides a method for testing the heat dissipation performance of a radiator assembly, the radiator assembly has a built-in oil cooler, and the method includes:

[0076] Step 101: Obtain the operating parameters of the radiator assembly under actual vehicle conditions according to the engine and gearbox bench tests, and the operating parameters of the radiator assembly under actual vehicle conditions include at least: the inlet water temperature of the radiator , water flow of radiator, forward air temperature of radiator, air flow of radiator, oil inlet temperature of oil cooler, oil flow of oil cooler.

[0077] Step 102: According to the operating parameters of the radiator assembly under the actual vehicle working conditions, the radiator assembly is subjected to an air duct test to obtain the operating parameters of the air duct experiment of the radiator assembly. The air duct test operating par...

Embodiment 2

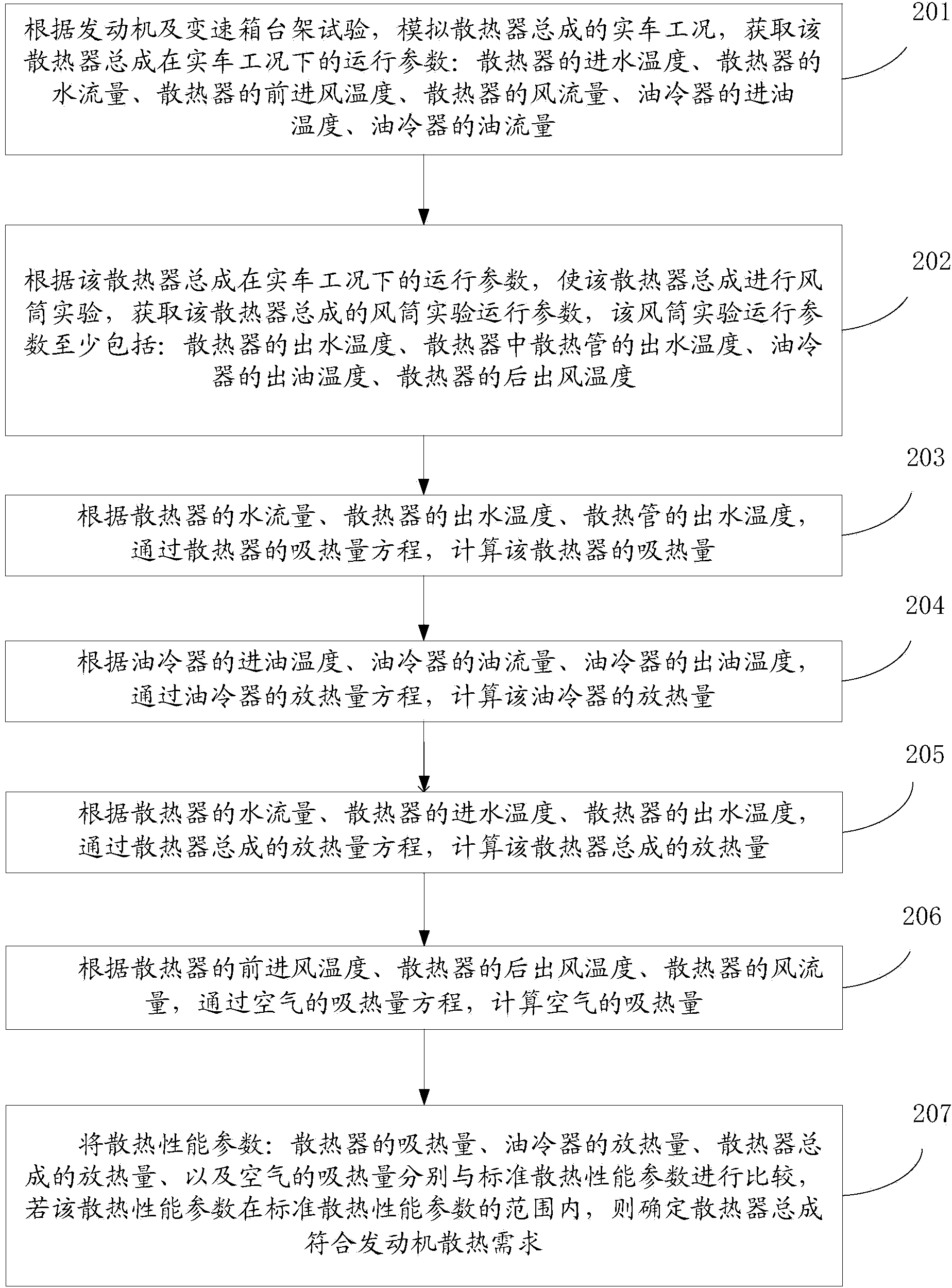

[0082] as attached figure 2 As shown, the embodiment of the present invention provides a method for testing the heat dissipation performance of a radiator assembly, the radiator assembly has a built-in oil cooler, and the method includes:

[0083] Step 201: According to the engine and transmission bench test, simulate the real vehicle working condition of the radiator assembly, and obtain the operating parameters of the radiator assembly under the real vehicle working condition: the inlet water temperature of the radiator, the water temperature of the radiator Flow rate, forward air temperature of radiator, air flow rate of radiator, oil inlet temperature of oil cooler, oil flow rate of oil cooler.

[0084] The car is composed of two major assemblies, the engine and the gearbox. The engine and gearbox test bench is a test bench that can fully reflect the actual performance of the whole vehicle. Various operating parameters under vehicle conditions. Since the engine and the ...

Embodiment 3

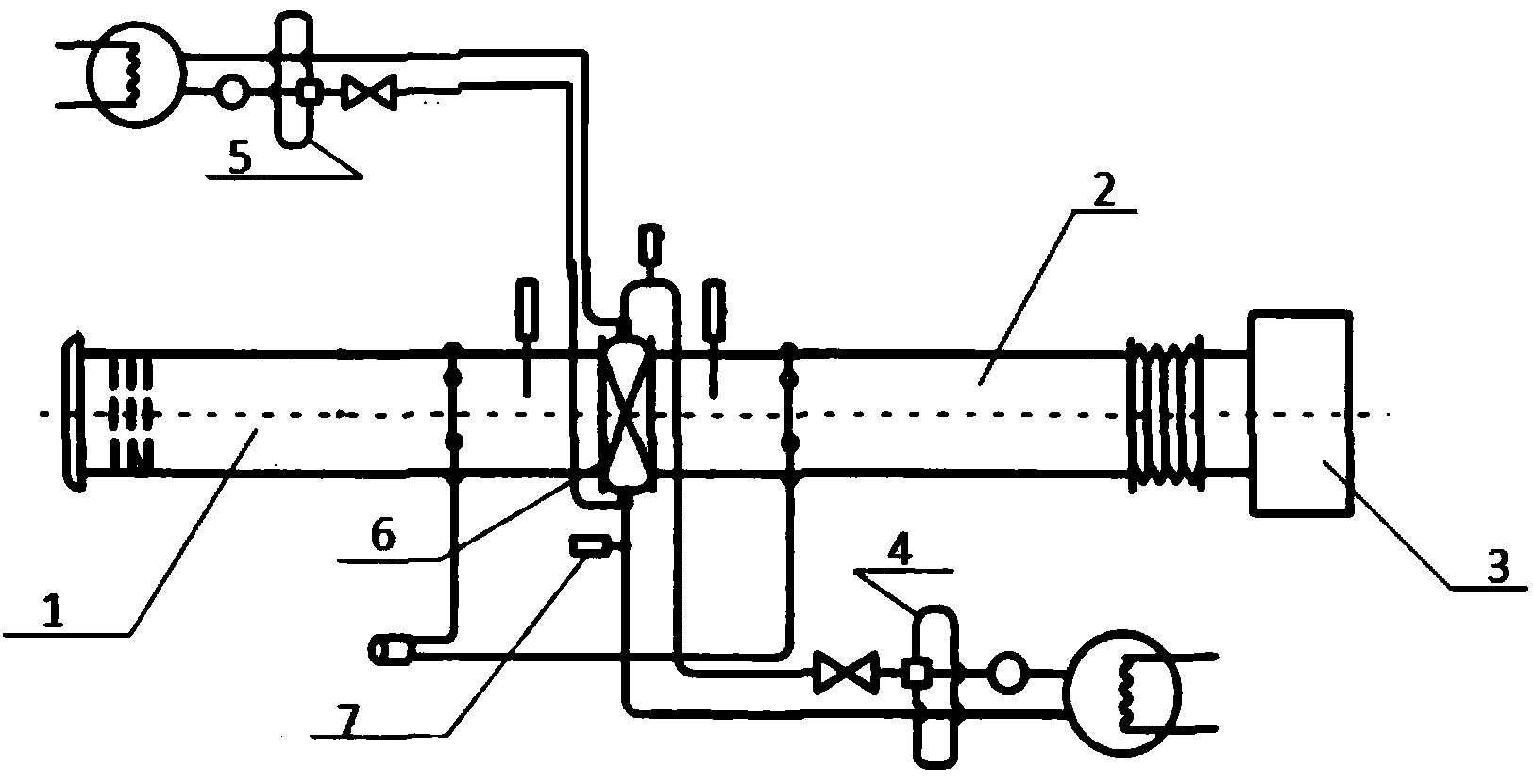

[0145] as attached Figure 4 As shown, the embodiment of the present invention provides a heat dissipation performance testing device for a radiator assembly, the radiator assembly has a built-in oil cooler, and the device includes:

[0146] The first acquisition module 301 is used to obtain the operating parameters of the radiator assembly under the actual vehicle working conditions according to the engine and gearbox bench tests, and the operating parameters of the radiator assembly under the actual vehicle operating conditions at least include: heat dissipation The water inlet temperature of the radiator, the water flow of the radiator, the forward air temperature of the radiator, the air flow of the radiator, the oil inlet temperature of the oil cooler, and the oil flow of the oil cooler.

[0147] The second acquisition module 302 is used to make the radiator assembly carry out the air duct test according to the operating parameters of the radiator assembly under the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com