A kind of tea-flavored yoghurt and preparation method thereof

A yogurt and tea-flavored technology, applied in the field of fermented dairy product processing, can solve the problems of not mentioning the influence of the fermentation process of tea components, the adverse influence of the number of active lactic acid bacteria, the easy loss of activity of functional components, and the like, so as to achieve good flavor and taste, The effect of improving fermentation flavor and avoiding nutrient destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

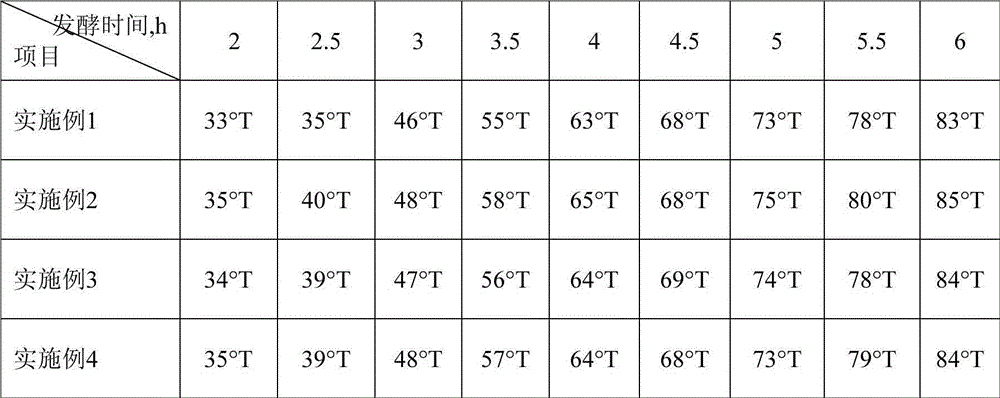

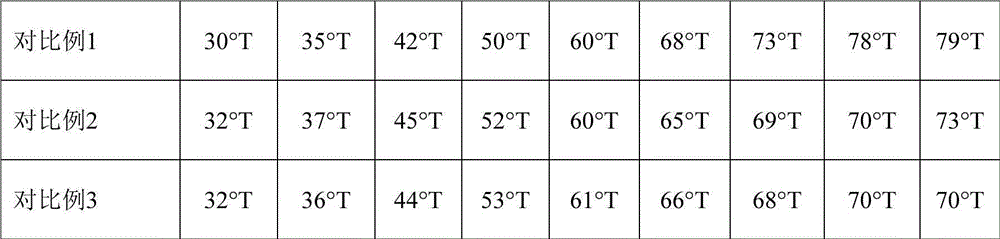

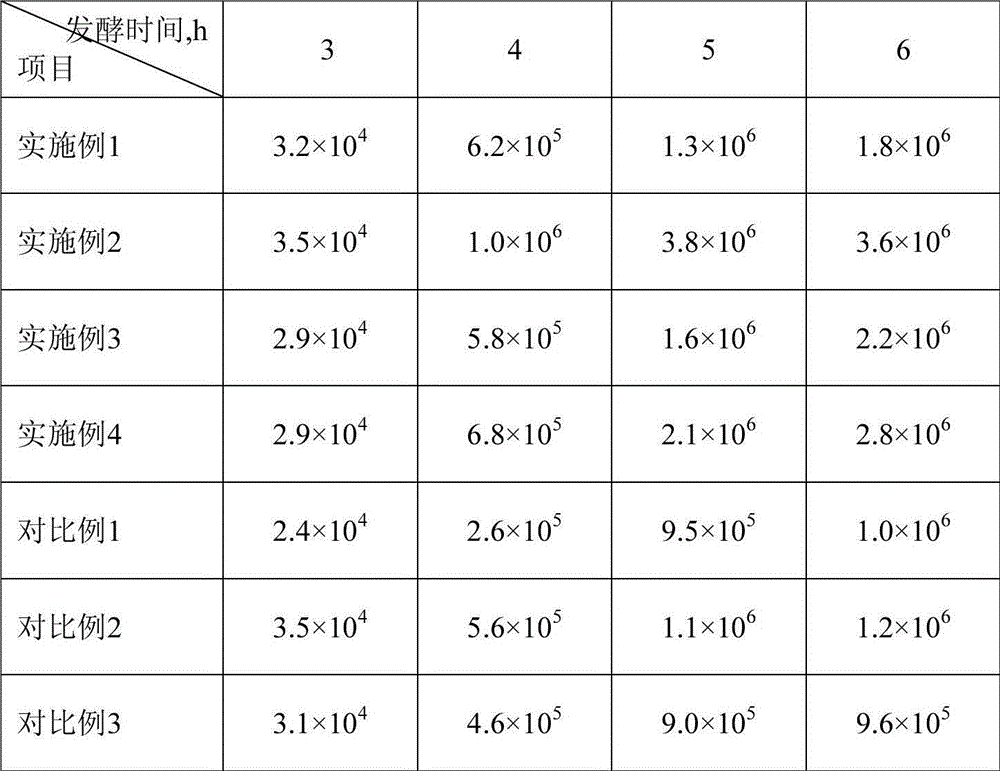

Examples

Embodiment 1

[0033] Embodiment 1, stirring type green tea flavored yoghurt

[0034] The preparation of the stirring type green tea flavor yoghurt of the present embodiment is carried out according to the following operations:

[0035] (1) Preparation of tea soup:

[0036] Inject 1 ton of pure water into the vacuum reactor, heat the water under natural pressure until it boils, and then cool down naturally. When the water temperature drops to about 80°C, add 10kg of green tea, and keep warm and extract for about 20 minutes under the condition of vacuum degree of 20KPa, which can be intermittent Supplemented with appropriate stirring, after the leaching is completed, first carry out coarse filtration (80°C), then rapidly cool to 5°C for fine filtration (5°C), to filter out insoluble components visible to the naked eye, and the filtrate is the product of this example. tea soup, spare;

[0037] (2) Preparation of tea soup reconstituted emulsion:

[0038] Tea Restoring Lotion Recipe:

[0039...

Embodiment 2

[0047] Embodiment 2, stirring type green tea flavored yoghurt

[0048] The preparation of the stirring type green tea flavor yoghurt of the present embodiment is carried out according to the following operations:

[0049] (1) Preparation of tea soup:

[0050] Inject 1 ton of pure water into the vacuum reactor, heat the water under natural pressure until it boils, and then cool down naturally. When the water temperature drops to about 85°C, add 50kg of green tea, and keep leaching for about 15 minutes under the condition of vacuum degree of 50KPa, which can be intermittent Supplemented with appropriate stirring, after the leaching is completed, first carry out coarse filtration (85°C), then rapidly cool to 5°C for fine filtration (5°C), to filter out insoluble components visible to the naked eye, and the filtrate is the product of this example. tea soup, spare;

[0051] (2) Preparation of tea soup reconstituted emulsion:

[0052] Tea Restoring Lotion Recipe:

[0053] Skimme...

Embodiment 3

[0061] Embodiment 3, stirring type oolong tea flavor yoghurt

[0062] The preparation of the stirring type oolong tea flavor yoghurt of the present embodiment is carried out according to the following operations:

[0063] (1) Preparation of tea soup:

[0064] Inject 1 ton of pure water into the vacuum reactor, heat the water under natural pressure until it boils, and then cool down naturally. When the water temperature drops to about 80°C, add 40kg of oolong tea, and keep warm and extract for about 15 minutes under the condition of vacuum degree of 50KPa. During this period, it can be intermittent Supplemented with appropriate stirring, after the leaching is completed, first carry out coarse filtration (85°C), then rapidly cool to 5°C for fine filtration (5°C), to filter out insoluble components visible to the naked eye, and the filtrate is the product of this example. tea soup, spare;

[0065] (2) Preparation of tea soup reconstituted emulsion:

[0066] Tea Restoring Lotio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com