Automatic pancake baking unit

A kind of unit and dough skin technology, which is applied in the direction of baking, baked food with modified ingredients, baked food processing, etc., can solve the problem of not being able to produce baked dough skin, achieve the effect of ensuring the taste and flavor, and realizing automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

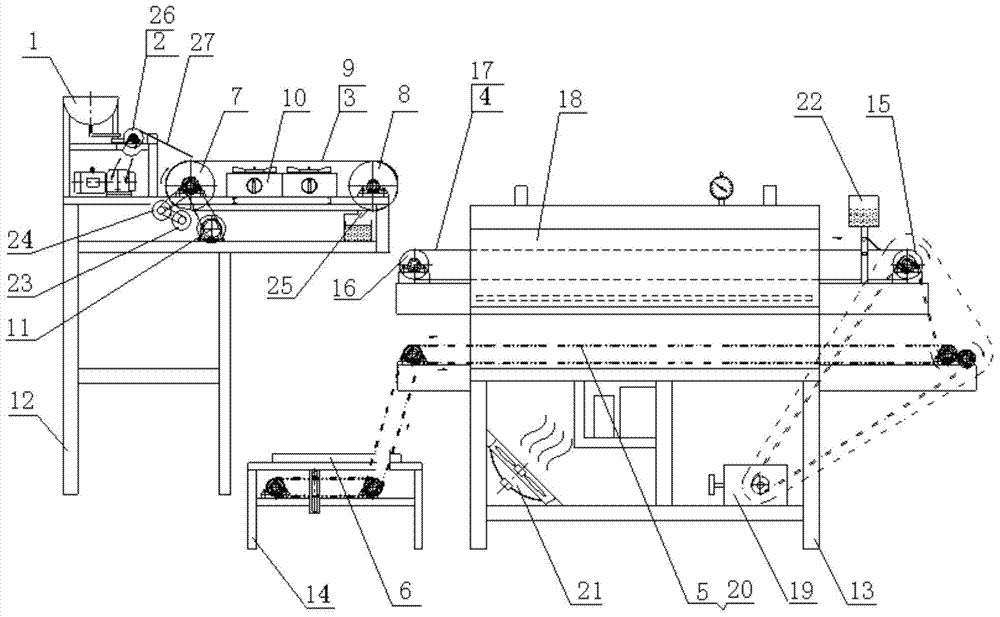

[0011] combined with figure 1 An embodiment of the present invention is described.

[0012] An automatic dough baking unit, which consists of a hopper 1, a material distributing device 2, a baking device 3, a curing device 4, a cooling device 5 and a material receiving device 6; the hopper 1 and the material distributing device 2 are arranged on the upper surface of the frame I12 and the hopper 1 is located above the material distribution device 2, and the discharge end of the material distribution device 2 is located above the feed end of the melting device 3; the aging device 4 and the cooling device 5 are all arranged on the frame II13, and the cooling device 5 is located below the curing device 4, and the feed end of the curing device 4 is located below the discharge end of the melting device 3; the material receiving device 6 is arranged on the frame III14, and the material receiving device 6 is located below the discharge end of the cooling device 5 .

[0013] The iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com