An improved method of tobacco cultivation under film

A tobacco seedling and film-covering technology, which is applied in the field of agricultural cultivation, can solve the problems of affecting the dry matter accumulation of tobacco plants, burning seedlings of tobacco plants, and unfavorable growth of lower leaves, so as to increase the biomass of tobacco plants, improve the quality of tobacco leaves, and highlight the fragrance style effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Materials and Methods

[0018] 1.1 Test method

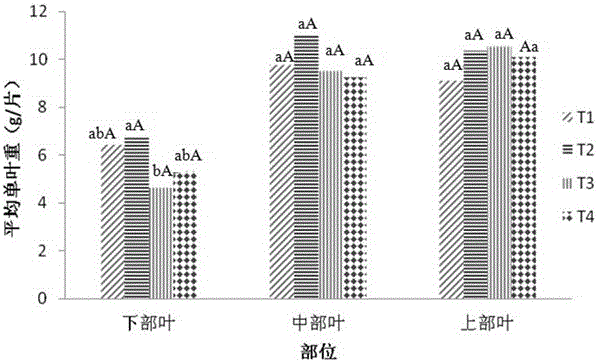

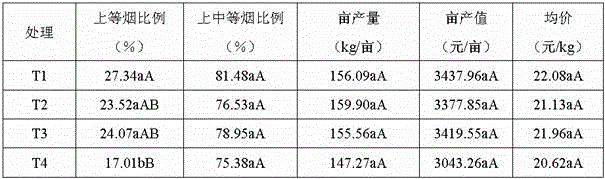

[0019] The Fuzhou Huanxi base of the Fujian Tobacco Research Institute was cultivated according to the following steps. A total of 4 treatments were set up to compare the effects of different seedling removal times on the growth and development of the tobacco plants and the yield and quality of the cured tobacco leaves:

[0020] T1: Transplanting under the film, and the seedlings were removed 2 weeks after the tobacco plants were transplanted;

[0021] T2: Transplanting under the film, the tobacco plants were removed 4 weeks after transplanting;

[0022] T3: Transplanting under the film, the tobacco plants were transplanted and the seedlings were removed after the tobacco seedlings were topped with film (38 days after transplanting);

[0023] T4: Control, deep planting on film.

[0024] 1.1.1 The main steps of transplanting under the film include:

[0025] 1) Seedling cultivation: from the end of October of the prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com