Basin type insulator

A basin-type insulator and ring-shaped technology, applied in the field of electric power, can solve the problems of limited application occasions, large joint parts, complex structure, etc., and achieve the effect of strong flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

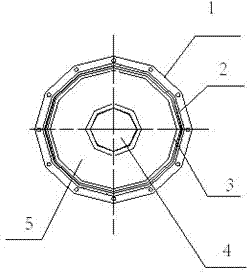

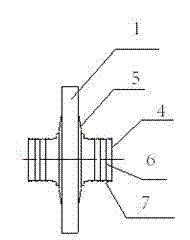

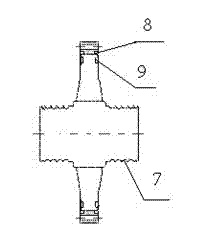

[0018] The pot insulator at least includes a cylindrical flange 1, a connecting conductor 4 and an insulating casting body 5; Left and right symmetrical with the annular insulating castable body 5 as the center; a cylindrical flange 1 is provided outside the annular insulating castable body 5; the upper and lower surfaces of the annular insulating castable body 5 near the outer circle are respectively provided with annular first grooves 8. The first O-ring 2 is provided in the first groove 8; the upper and lower surfaces of the cylindrical flange 1 near the inner circle are respectively provided with an annular second groove 9; the second groove 9 is provided with There is a second O-shaped sealing ring 3; three annular conductive grooves 7 are arranged at both ends of the connecting conductor 4, and each annular conductive groove 7 is covered with a spring contact 6.

Embodiment 2

[0020] Such as figure 1 , figure 2 with image 3 As shown, the pot insulator at least includes a cylindrical flange 1, a connecting conductor 4 and an insulating casting body 5; the insulating casting body 5 is ring-shaped, and a connecting conductor 4 is arranged in the hole of the annular insulating casting body 5. The connecting conductor 4 is left-right symmetrical with the annular insulating casting body 5 as the center; a cylindrical flange 1 is arranged outside the annular insulating casting body 5; the insulating casting body 5, the connecting conductor 4 and the cylindrical flange 1 form an integrated structure through casting. The upper and lower surfaces of the annular insulating casting body 5 near the outer circle are respectively provided with annular first grooves 8, and a first O-ring sealing ring 2 is arranged in the first groove 8; the cylindrical flange 1 is close to The upper and lower surfaces of the inner circle are respectively provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com