Spraying electric mark resistance test device

A test device and a technology of resistance to electric traces, which are applied in the direction of measuring devices, measuring device casings, and measuring electricity, can solve the problems of pictures and videos that cannot capture and record leakage traces in time, salt spray parameters that cannot be automatically adjusted, and tests that cannot be clearly defined Observation and recording etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

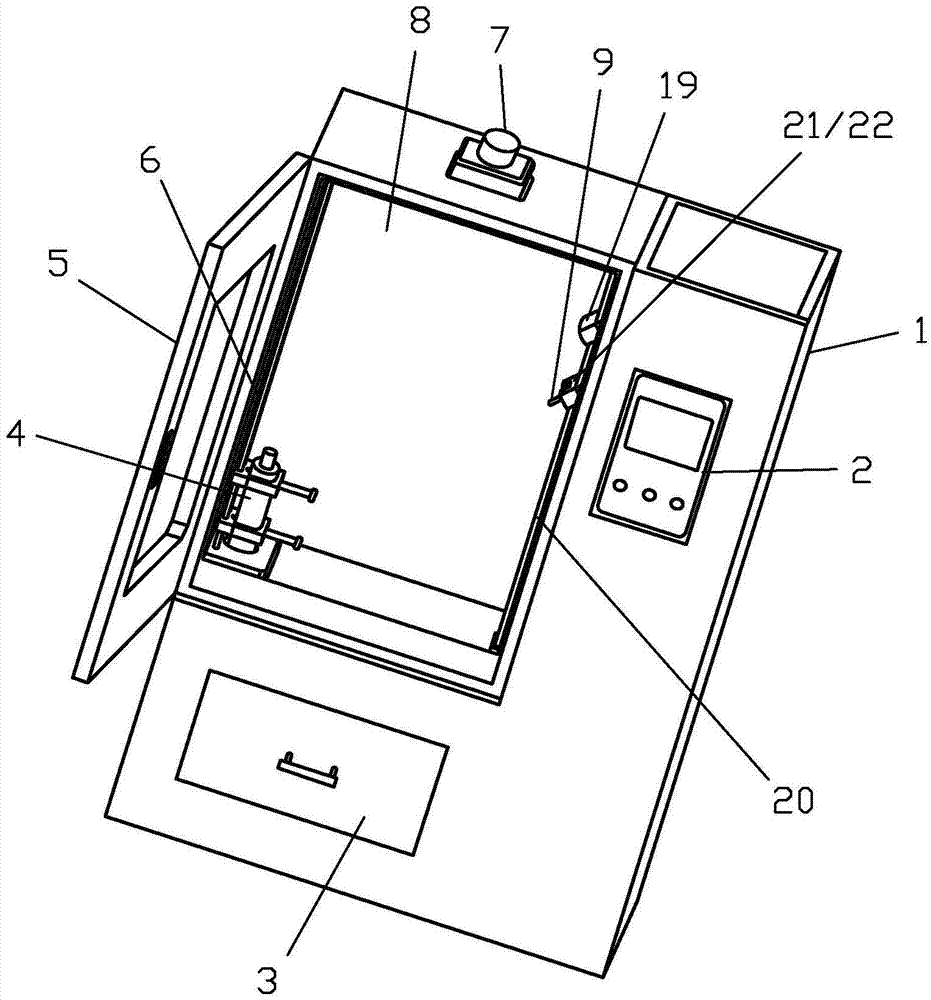

[0033] refer to figure 1 , The spray tracking resistance test device of the present invention includes a cabinet 1 and a cabinet door 5 . The cabinet 1 is provided with a microprocessor and a microprocessor control panel 2 . The top of the chassis 1 is provided with an exhaust hood 7, and is equipped with an automatic air distribution system and a test liquid collection and discharge device. A drawer 3 is arranged in the lower part of the case 1 . The cabinet 1 is provided with a spray chamber 8, and the spray chamber 8 is provided with a pair of left guide rods 6 and a pair of right guide rods 20, and a clamp device is provided below the left guide rod 6, and the A spray seat and a camera 19 are arranged above the right guide rod 20, and a spray head is arranged on the spray seat.

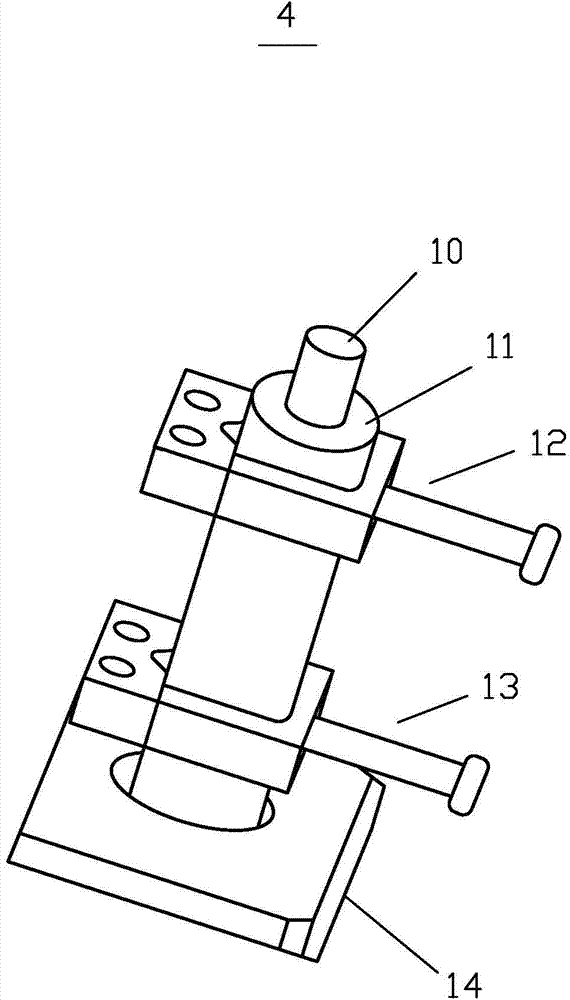

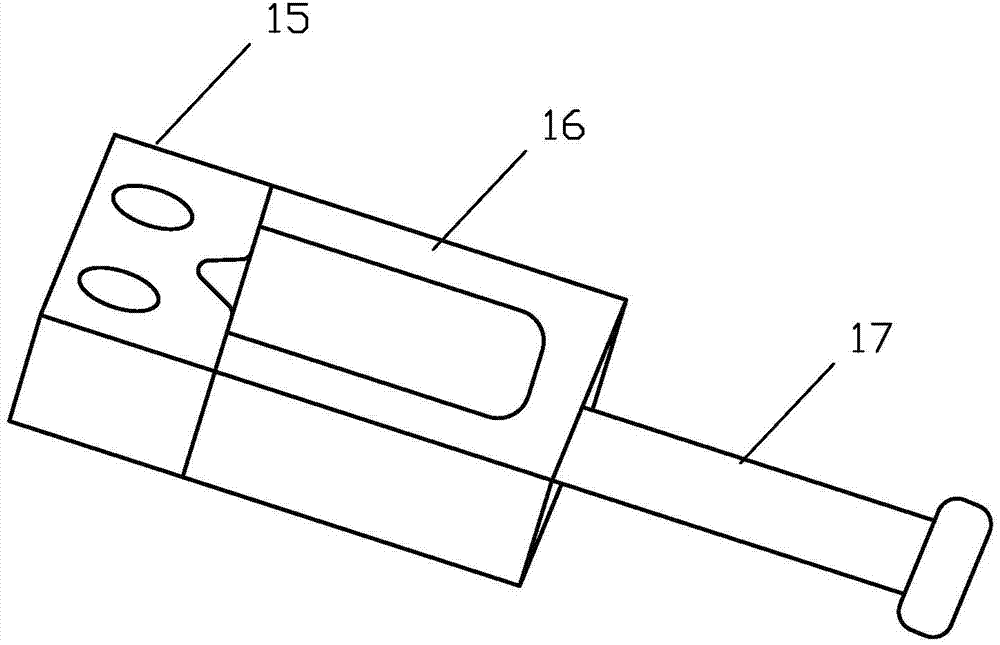

[0034] refer to Figure 1-Figure 12 , the clamp device includes an upper clamp 12, a lower clamp 13 and a base 14; the upper clamp 12 includes a clamp block 15, a clamp lock block 16 and a fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com