Fire product test device

A fire-fighting product and inspection device technology, which is applied in the direction of using liquid/vacuum to measure liquid tightness and applying stable tension/pressure to test the strength of materials, etc., which can solve the problems of slow detection speed, inaccurate data, and prone to deviation of data and other issues, to achieve the effect of safe use, accurate detection data, and clean exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

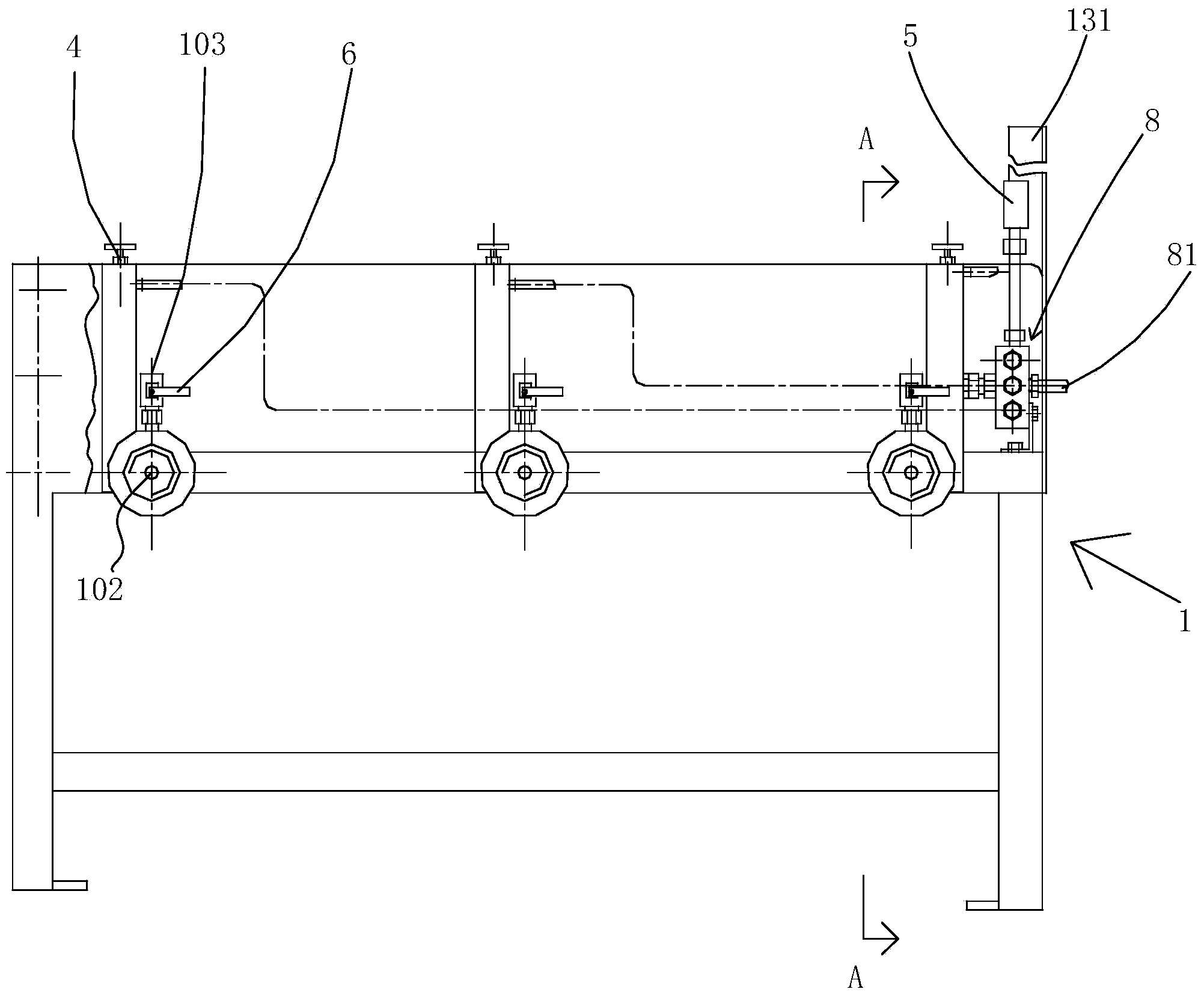

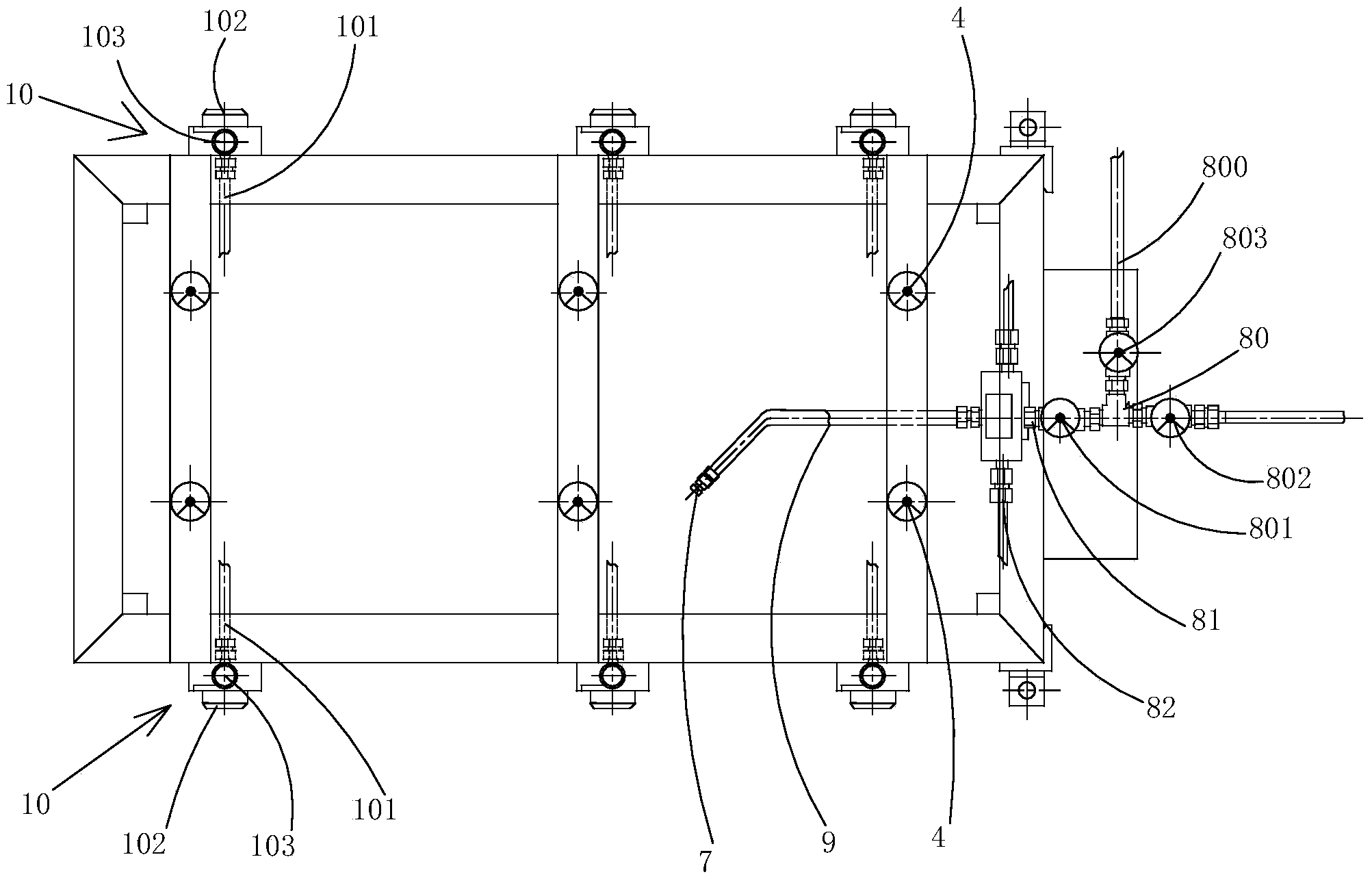

[0030] Please refer to Figure 1-4 Shown, a kind of fire product inspection device, it comprises test bench device 1, electric pressure test pump 2 and air pressure tank 3; Said electric pressure test pump 2 is connected with the inlet of air pressure tank 3 so as to provide water source to air pressure tank 3 and compress the air in the air pressure tank 3 to make it a reserve pressure source; the test bench device 1 is a sample workbench with a horizontal structure, and the test bench device 1 is provided with a water flow splitter 8 and a plurality of Install the fire-fighting product sample or install the product connector 10 to be inspected with the fire-fighting product sample tooling fixture, the water flow distribution joint 8 includes a water inlet 81 and a plurality of water outlets 82 communicated with the water inlet 81 at the same time, the water flow distribution joint 8 The water inlet 81 of the air pressure tank 3 is connected with the outlet of the air pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com