Cement water-permeable concrete ground structure with water-permeable asphalt on surface and manufacturing method thereof

A technology of permeable concrete and permeable asphalt is applied to the coagulation pavement, roads, roads and other directions of on-site paving, which can solve the problems of inability to directly infiltrate rainwater, difficult municipal vehicle roads, and inconvenient repairs, etc. Urban heat island effect, effect of supplementary groundwater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

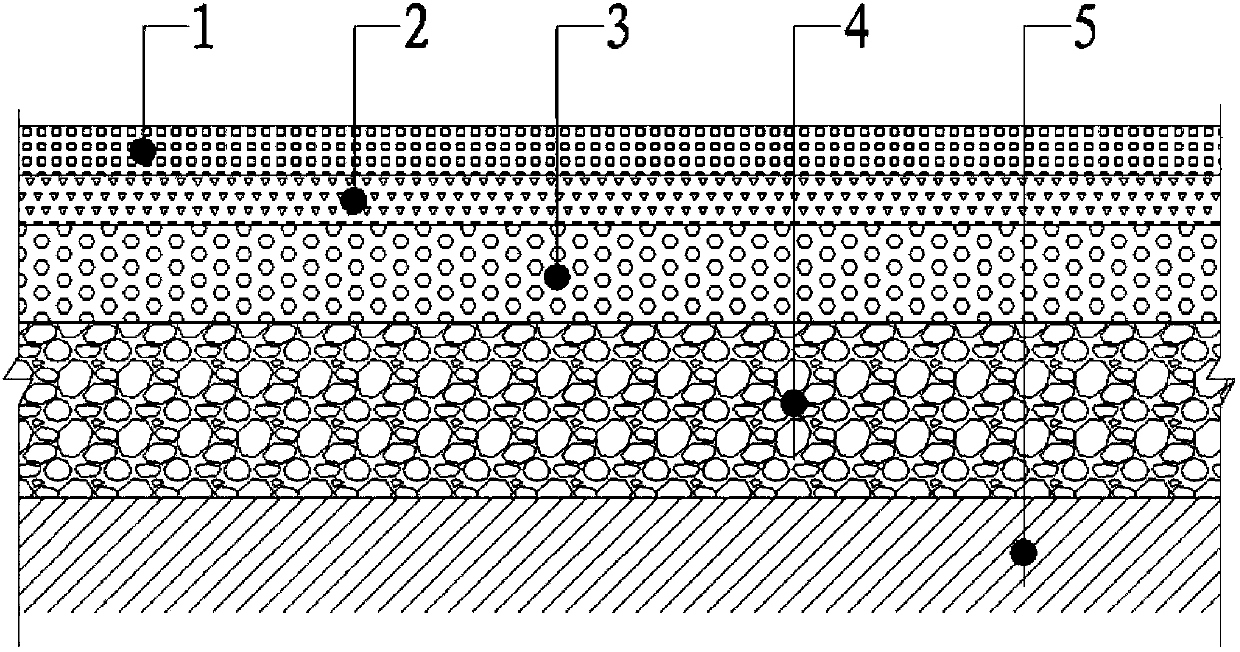

[0022] Below in conjunction with accompanying drawing, the present invention is specifically described, as figure 1 It is a schematic diagram of the cement permeable concrete ground structure of permeable asphalt according to the present invention. The pavement structure includes at least one layer of asphalt permeable concrete layer (1), at least one layer of cement permeable concrete layer (3), and a cushion layer (4), The base layer (5), the above-mentioned layers are arranged sequentially from top to bottom, is characterized in that permeable asphalt concrete and cement permeable concrete are combined.

[0023] Among them, the asphalt permeable concrete layer is formed by laminating one or more layers of asphalt permeable concrete; the separation layer can be laid or not laid; the cement permeable concrete layer is formed by laminating one or more layers of cement permeable concrete; the asphalt permeable concrete layer and cement permeable concrete A separation layer can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com