Disc recliner with internal leaf springs

一种斜倚器、板弹簧的技术,应用在盘状斜倚器领域,能够解决致动力不合需要等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

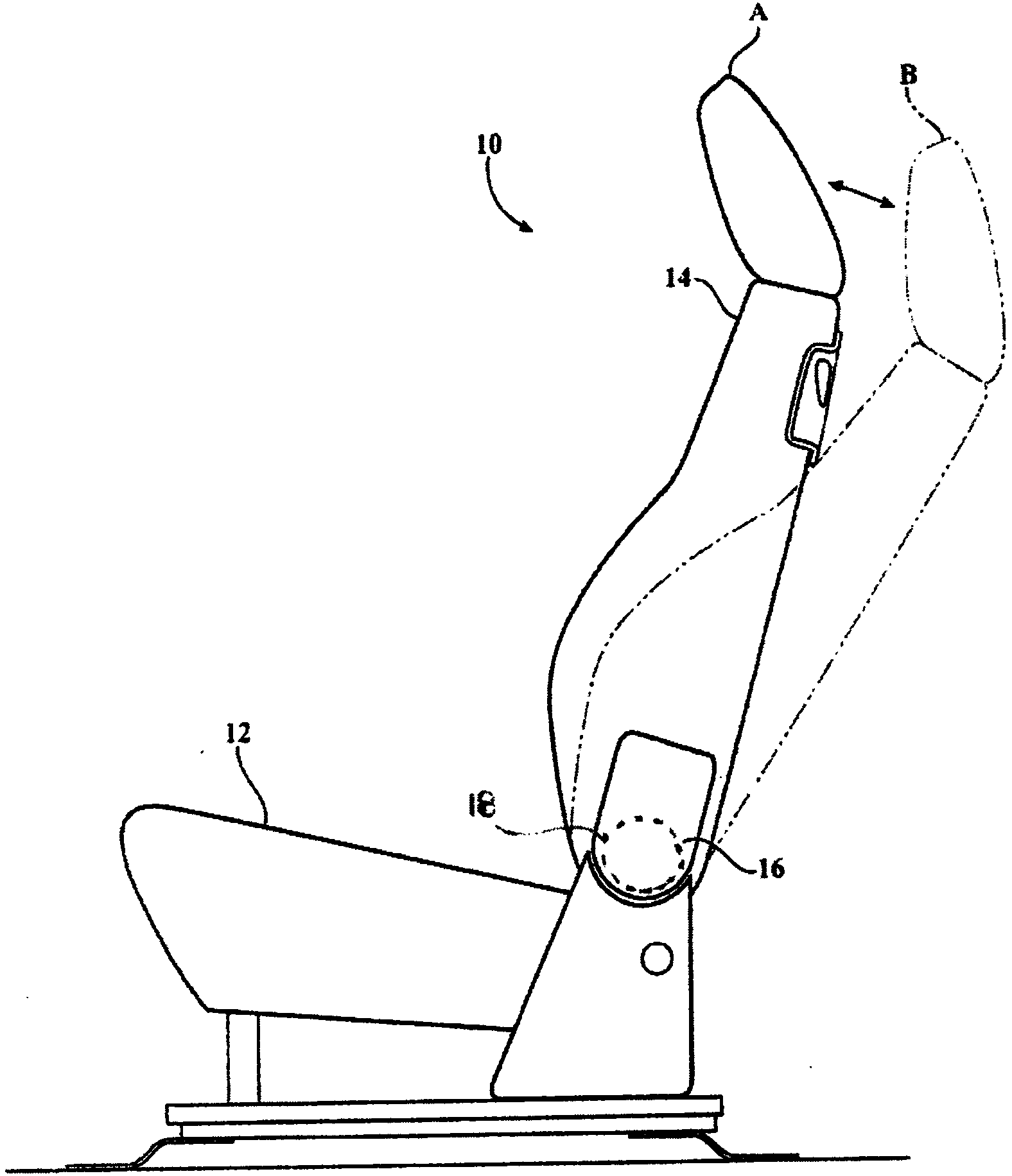

[0019] Referring to the drawings, wherein like reference numerals indicate like or corresponding parts throughout the several views, a seat assembly for use in an automotive vehicle is shown generally at 10 . refer to figure 1 The seat assembly 10 includes a generally horizontal seat cushion 12 and a generally vertical seat back 14 operatively and pivotally coupled to the seat cushion 12 by a recline assembly 16 . The recline assembly 16 includes a pair of spaced and synchronized disc recliners 18 (one disc recliner shown).

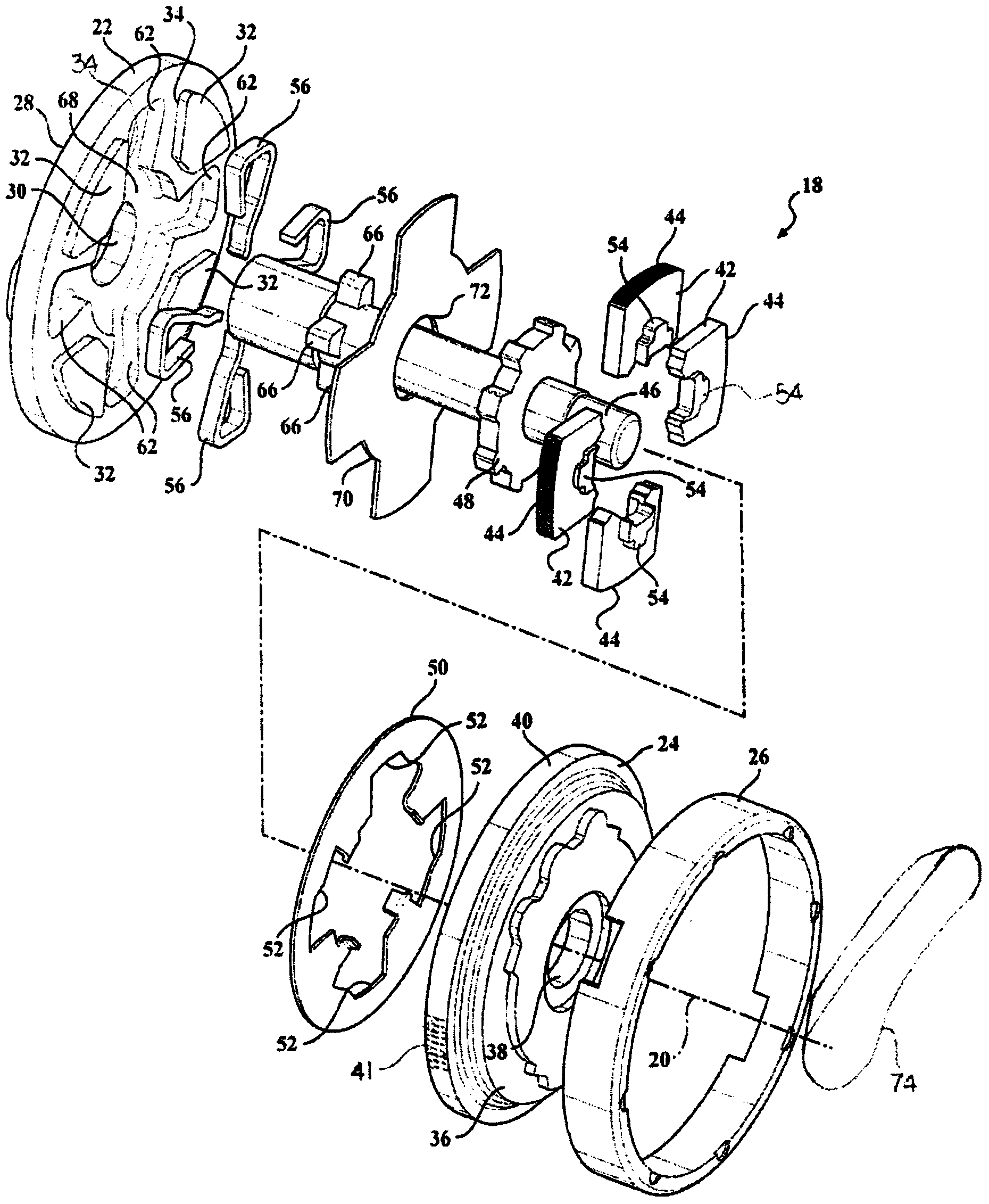

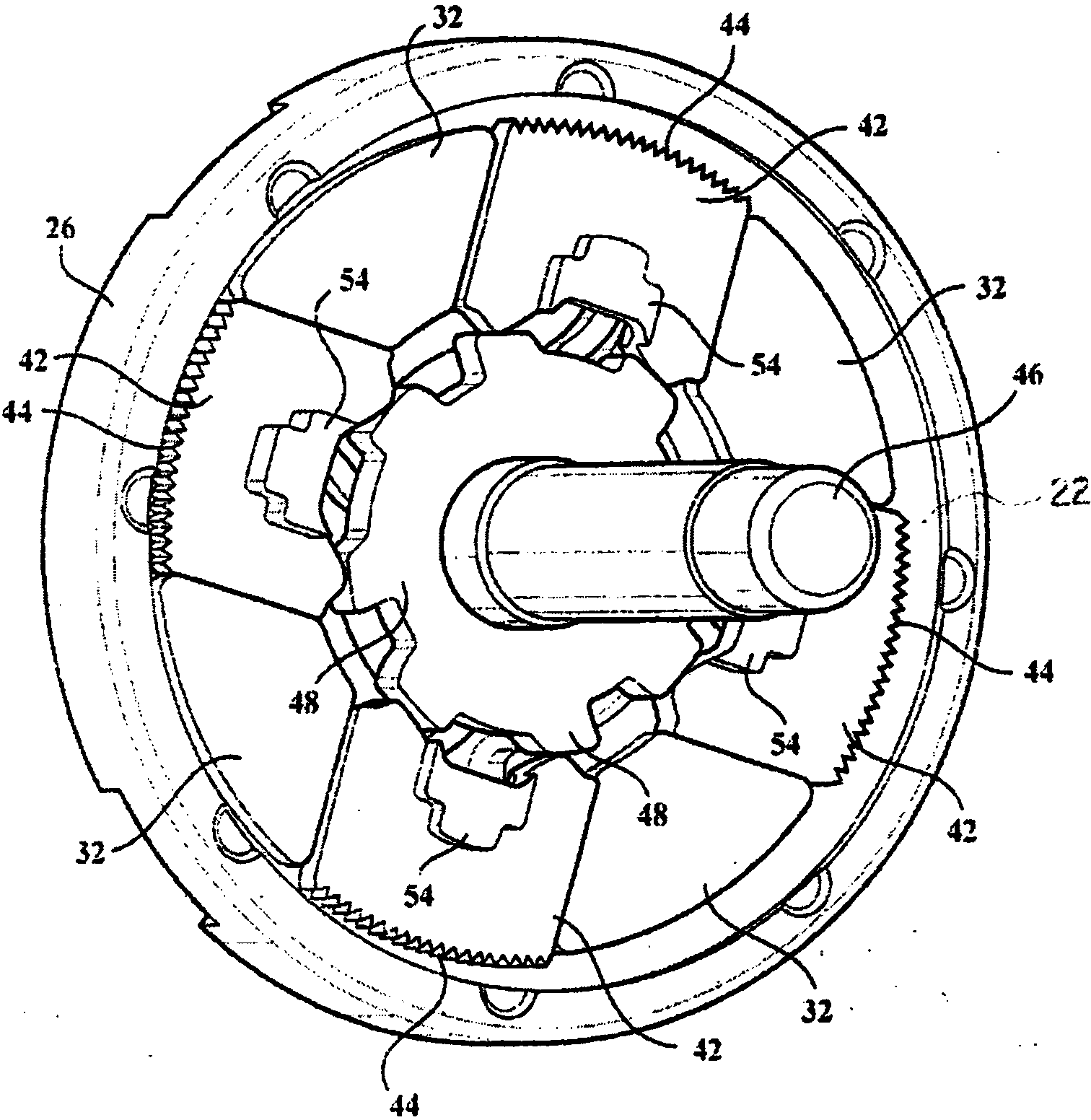

[0020] refer to Figure 2 to Figure 6 , the disc recliner 18 is operable between a locked state, in which the disc recliner 18 prevents pivotal movement of the seat back 14 relative to the seat cushion 12, and an unlocked state, , the disc recliner 18 permits pivotal movement of the seat back 14 relative to the seat cushion 12 about a laterally extending axis 20 between an upright sitting position A and a plurality of reclined sitting positions. One of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com