Novel photovoltaic-panel two-dimension-motion control system driven by single motor

A motor-driven, two-dimensional motion technology, applied in the direction of control using feedback, can solve the problems of increasing the power consumption and waste of the tracking device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

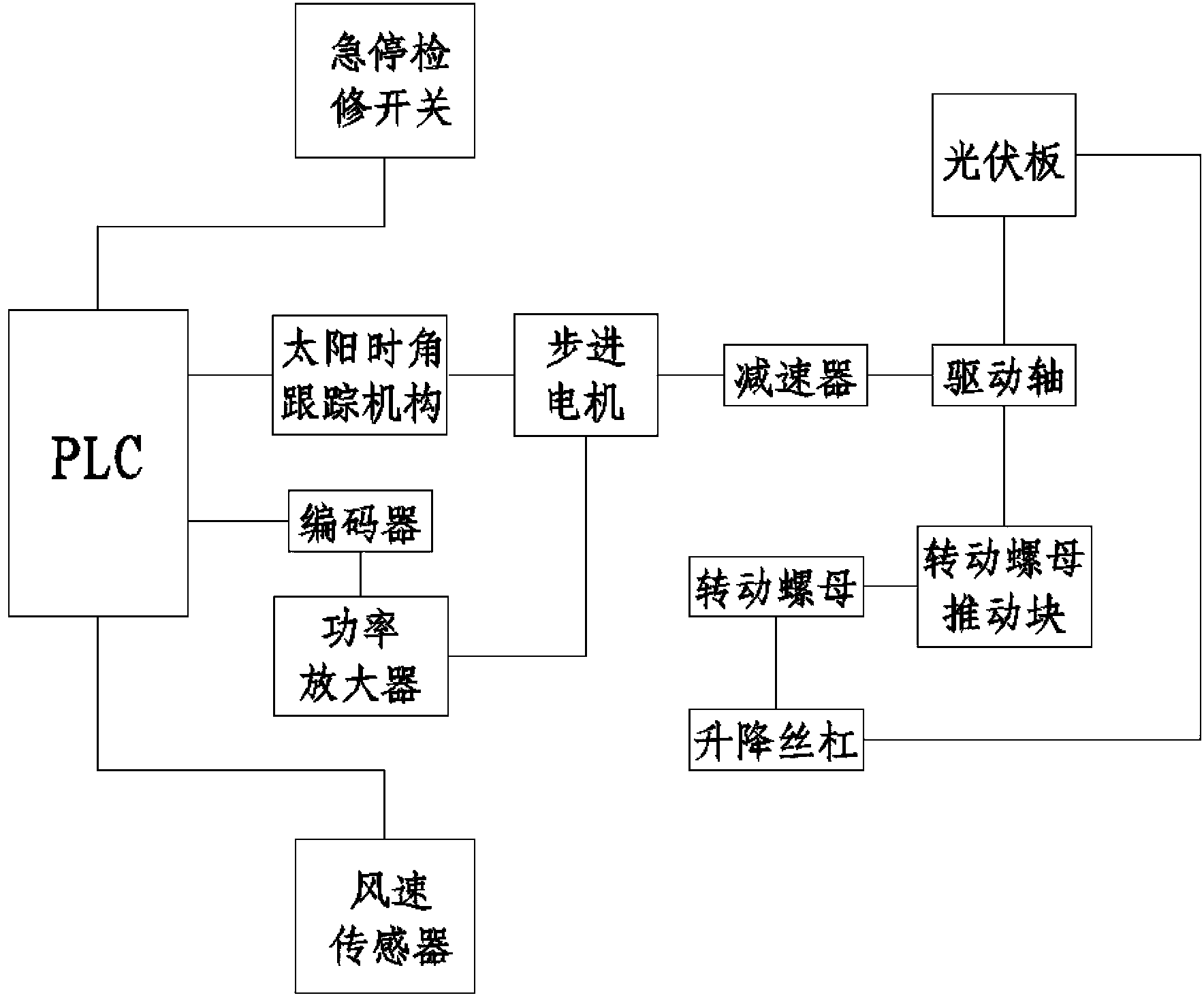

[0013] As shown in the accompanying drawing, it shows an embodiment of the present invention. The photovoltaic panel two-dimensional motion control system driven by a single motor of the present invention includes a PLC (programmable logic controller) installed in the control box, and the PLC controls the sun Hour angle tracking mechanism, the sun hour angle tracking mechanism is a rotating mechanism parallel to the earth's rotation axis, a stepping motor is included in the sun hour angle tracking mechanism, the output shaft of the stepping motor is connected to a reducer, and the reducer is Worm gear reducer, the output shaft of the reducer is connected to the drive shaft parallel to the earth's rotation axis, and photovoltaic panels are installed on the drive shaft;

[0014] The end of the above-mentioned drive shaft is also equipped with a rotating nut pushing block for driving the rotating nut to rotate. The inner threaded hole of the rotating nut is engaged with a lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com