Internally-geared machine

A gear machine, internal gear pump technology, applied in mechanical equipment, machines/engines, rotary piston machines, etc., can solve the problem that the balance pressure is not constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

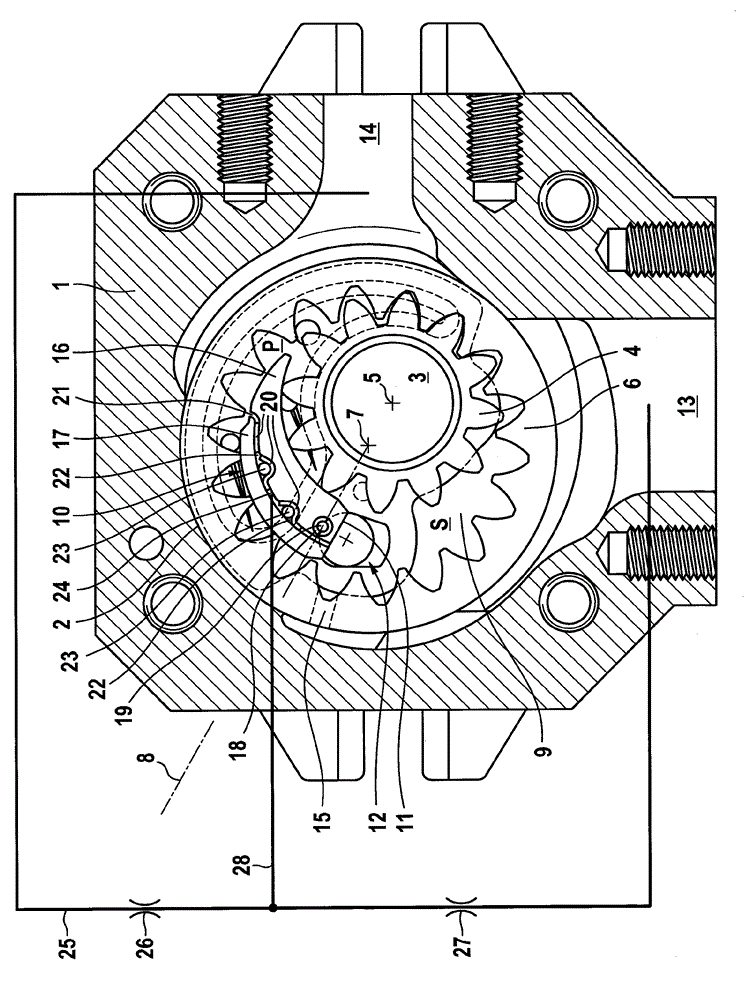

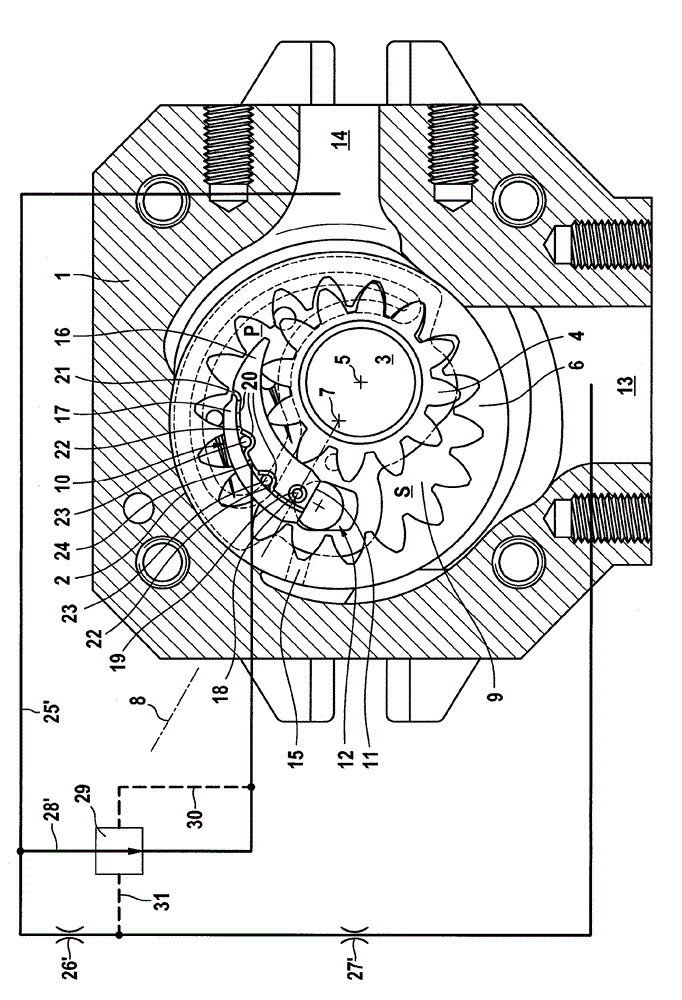

[0014] exist figure 1 The internal gear machine shown in has a housing, an annular middle part 1 of which can be seen. The central part 1 encloses a pump chamber 2 which is closed off by two side parts, not shown, of the housing. In both side parts, a drive shaft 3 is rotatably mounted. On the drive shaft 3 , an externally toothed pinion 4 is arranged in a rotationally fixed manner in the pump chamber 2 , the gear axis 5 of which coincides with the longitudinal axis of the drive shaft 3 .

[0015] The ring gear of pinion 4 has twelve teeth. The pinion is surrounded by an internally toothed ring gear 6 with eighteen teeth, the gear axis 7 of which runs parallel to and eccentrically to the gear axis 5 of the pinion. A center plane 8 extends through the gear axes 5 and 7 .

[0016] The ring gear 6 is mounted rotatably with its radially surrounding cylindrical shell surface in the corresponding circular pump chamber 2 of the central part. In the area of both sides of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com