White titania pearlescent pigment

A pearlescent pigment and titanium dioxide technology, applied in the field of pigments, can solve the problems of brightness, low saturation, weak interference effect, easy fading, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

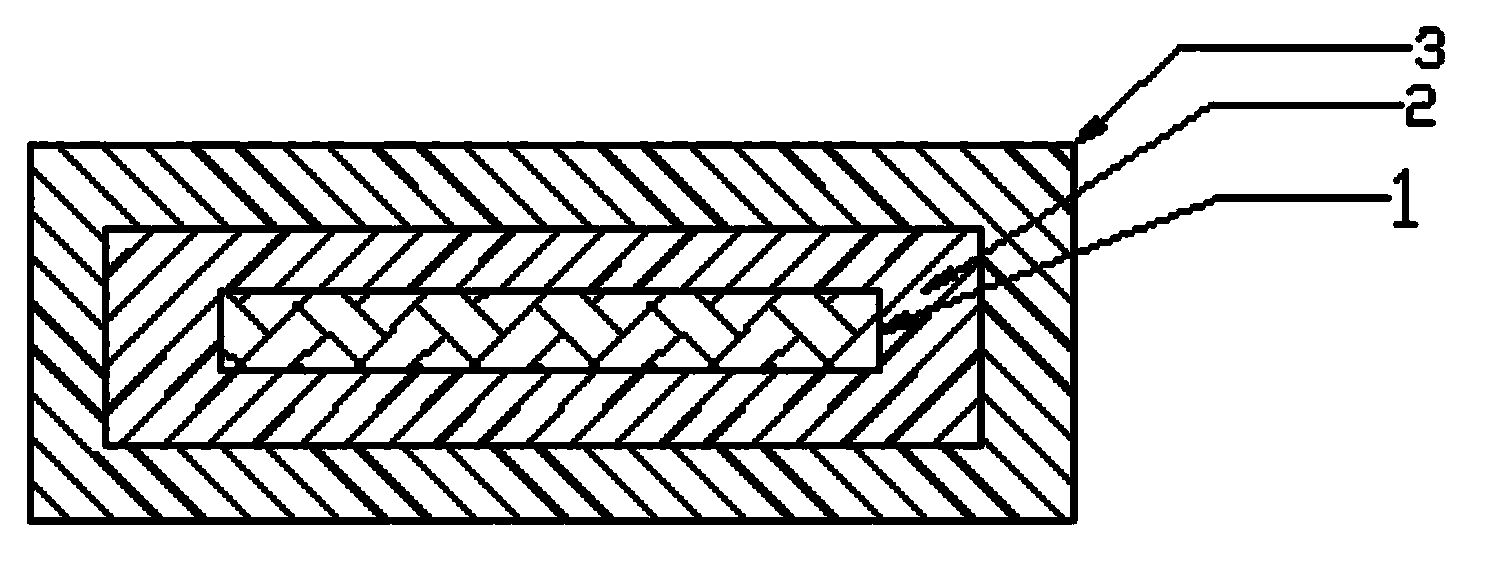

[0013] Example: This embodiment provides a white titanium dioxide pearlescent pigment, which includes a base material 1, the base material is coated with a layer of aluminum hydroxide gel film 2, and the aluminum hydroxide gel film is also coated with a layer of coloring agent 3, A metal oxide composite coating layer is formed.

[0014] The coloring agent is ferric oxide or other metal oxides.

[0015] The base material is lithopone.

[0016] In the specific implementation process, at a temperature of 70°C-80°C, the stirring of the substrate suspension is kept, the pH value of the reaction is stable, and the surface of the substrate is coated with aluminum hydroxide gel and ferric oxide in sequence, and the reaction is completed. Filtration, washing with deionized water, drying, calcination and other processes, the white titanium dioxide pearlescent pigment is obtained.

[0017] The titanium white pearlescent pigment of the present invention has the effect of different col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com