Formula for producing special blending fertilizer for paddy rice by combining calcium magnesium phosphate powder with fertilizer source of granular superphosphate

A calcium-magnesium-phosphate fertilizer and blended fertilizer technology, applied in fertilizer mixture, application, fertilization device and other directions, can solve problems such as ignorance of crop fertilizer requirements, farmers unaware of chemical fertilizer characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] specific implementation plan

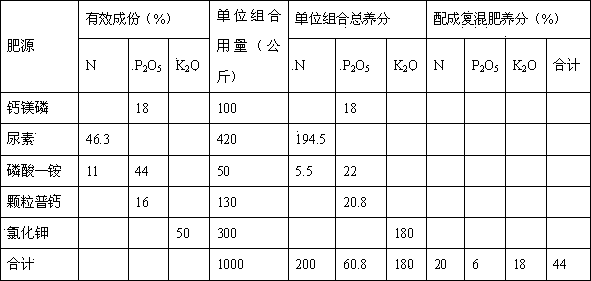

[0006] With 100 kilograms of its high-quality calcium magnesium phosphorus powder, 420 kilograms of compatible urea, 50 kilograms of monoammonium phosphate, 130 kilograms of granular common calcium, 300 kilograms of potassium chloride, dry mixing and mixing, sub-bag packaging, put on the market, for production, The total nutrient content of the blended fertilizer NPK is 44%, and the ratio of nitrogen, phosphorus, and potassium is 20:8:18; see the following table for specific blending parameters:

[0007]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com