A sink structure for the roof of a minibus

A technology of flow trough structure and mini-bus, applied in the directions of superstructure, upper structure sub-assembly, vehicle components, etc., can solve the problems of troublesome assembly, complex flow trough structure, quality problems, etc., to achieve convenient assembly and eliminate the risk of quality problems , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

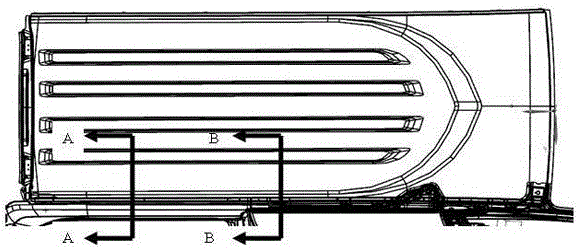

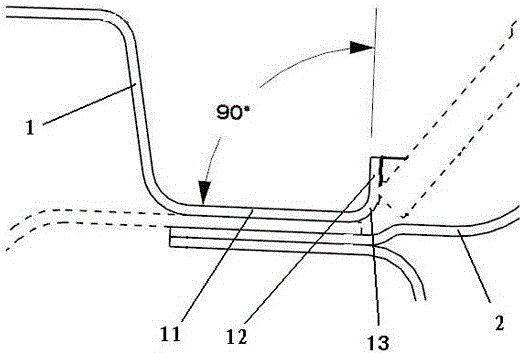

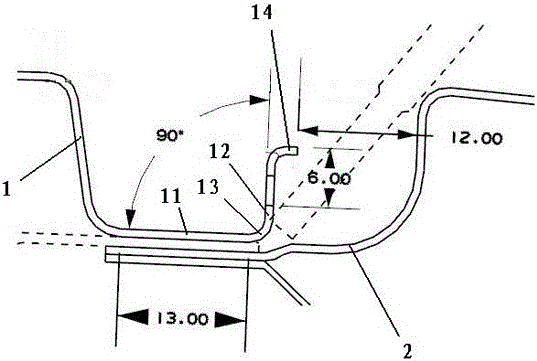

[0019] Figure 1 to Figure 3 The reference numerals in the drawings are: top cover 1; welded plate 11; right-angle flange 12; rounded corner 13; hook 14;

[0020] Figure 1 to Figure 3 The dotted line in is the glue gun used for coating and gluing.

[0021] Such as Figure 1 to Figure 3 As shown, a trough structure of a minibus roof includes a roof 1 and a side wall 2, the edge of the roof 1 is bent with a welded plate 11, and the roof 1 is connected to the welded plate 11. The side wall 2 is welded, and the edge of the welding plate 11 is bent with a right-angle flange 12, and the angle between the welding plate 11 and the right-angle flange 12 is 90 degrees.

[0022] Such as Figure 1 to Figure 3 As shown, the connection between the right-angle flange 12 and the welding plate 11 is provided with rounded corners 13 .

[0023] Such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com