Torsion bar for seat belt retractor, seat belt retractor and seat belt assembly

A technology of seat belt retractor and torsion bar, applied in the field of seat belts, can solve the problem of not providing seat belt modification, etc., and achieve the effect of protecting users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

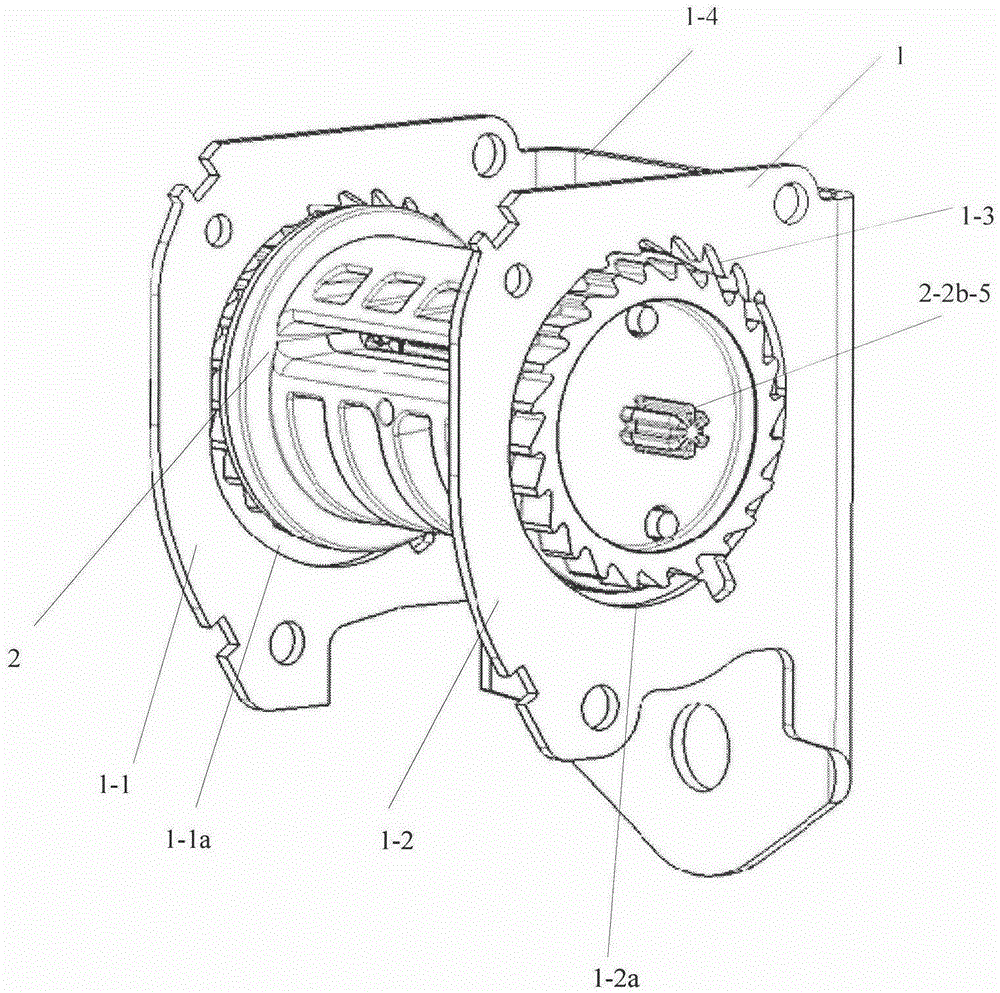

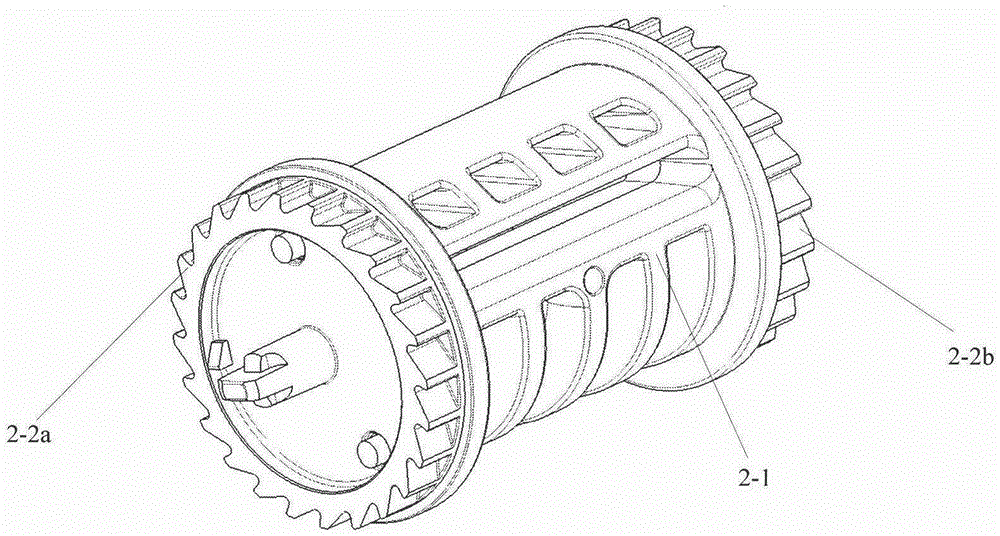

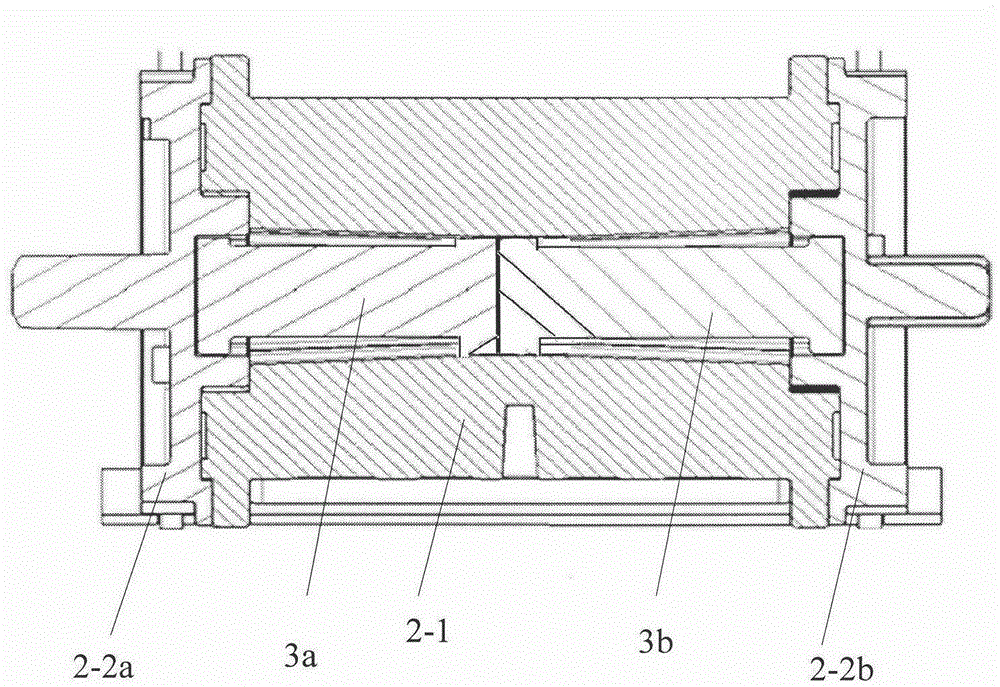

[0051] In this embodiment, the torsion bar is rod-shaped, and the torsion bar is divided into two sections in the axial direction. Both ends of each segment are provided with circumferential external teeth, please refer to Figure 5 , which is a structural schematic diagram of a section of the first embodiment of the torsion bar of the present invention, and the two ends of the torsion bar section 3a are provided with external teeth 3-2a and external teeth 3-2b. When the two sections of torsion rods are integrated, the two ends of the two sections of torsion rods are butted together, the end surfaces are in contact with each other, and the outer teeth of the opposite ends are aligned with each other to form an integral torsion rod. The outer teeth located at the two outer ends of the torsion bar match with the inner teeth of the central concave holes on the end faces of the two end caps of the retractor (the matching relationship between the torsion bar and the retractor is de...

no. 2 example

[0079] Please refer to Figure 12 , which is a schematic diagram of the second embodiment of the torsion bar of the present invention. In this embodiment, the torsion bar is an integral type, and circumferential external teeth (external teeth 3-2, external teeth 303 and external teeth 3-1) are also arranged at both ends and the middle of the torsion bar, wherein the torsion bar is located in the middle of the torsion bar. The effective lengths of the rod segments 3a and 3b on both sides of the circumferential external teeth 3-1 are different in the axial direction. Other aspects of the structure of the torsion bar in this embodiment and the assembly and cooperation relationship with the seat belt retractor are the same as those of the first embodiment above, and have the same technical effect as the torsion bar of the first embodiment above, here No longer.

[0080] In addition, the axial length of the torsion bar of the present invention can also be greater than the axial l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com