Vacuum adsorption head and adsorption device with same

A vacuum suction head and suction device technology, applied in the direction of chucks, manufacturing tools, manipulators, etc., can solve the problems of easily damaged magnetic head arms, slow suction speed, inaccurate alignment, etc., and achieve simple structure, convenient use, and smooth structure Simple effect of control principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

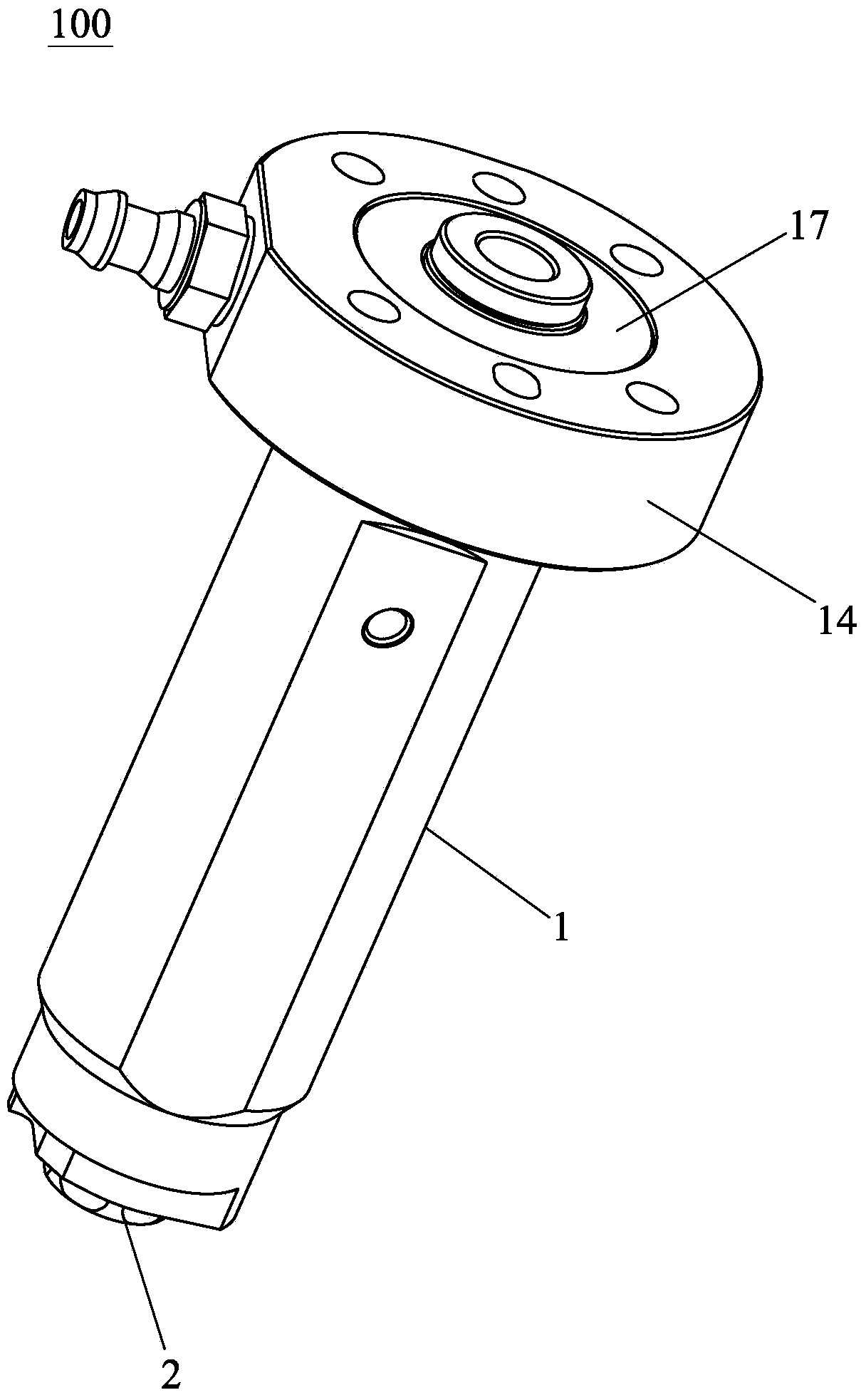

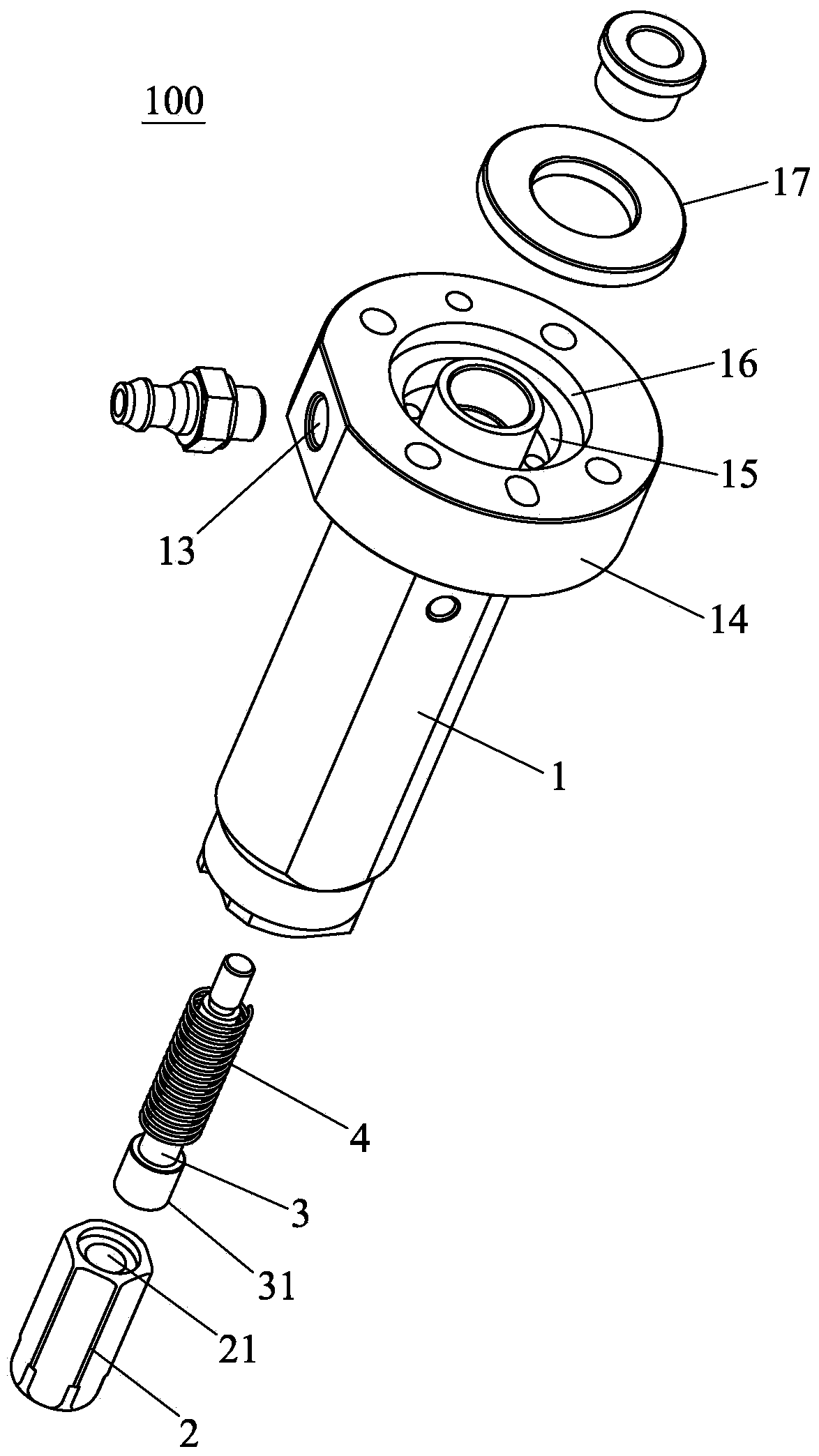

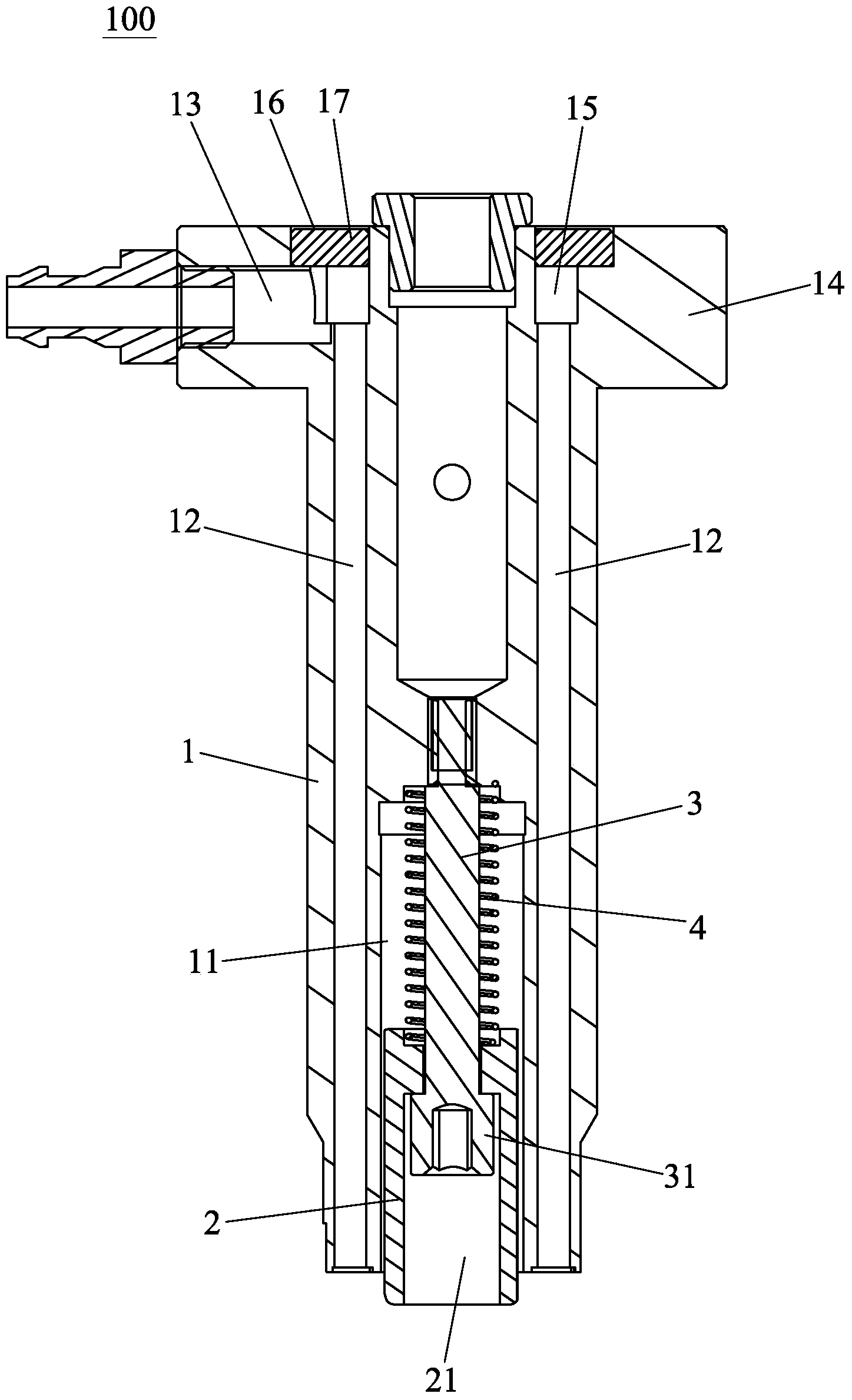

[0022] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0023] Such as figure 1 , figure 2 and image 3 As shown, the vacuum suction head 100 of the present invention includes a suction head main body 1, a positioning member 2, a guide rod 3 and a reset element 4. The suction end of the suction head main body 1 is provided with an accommodating hole 11 along the central axis and in the accommodating hole There are vacuum holes 12 on both sides of 11, the installation end of the suction head body 1 is provided with a vacuum channel 13, and the vacuum channel 13 communicates with the vacuum hole 12; One end of the guide rod 3 is fixed on the inner bottom surface of the accommodation hole 11, and the other end is slidably sleeved in the positioning hole 21; specifically, the positioning hole 21 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com