A quantitative evaluation method for qualitative factors of maintenance safety based on virtual maintenance

A qualitative factor, quantitative evaluation technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve problems such as lack of improvement guidance for qualitative factors, and achieve the effect of improving and improving implementation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

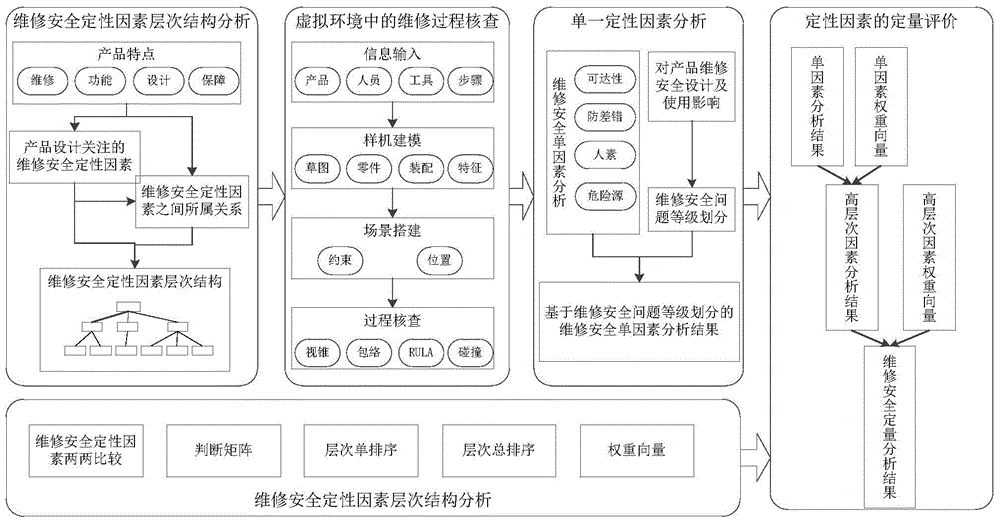

Method used

Image

Examples

Embodiment

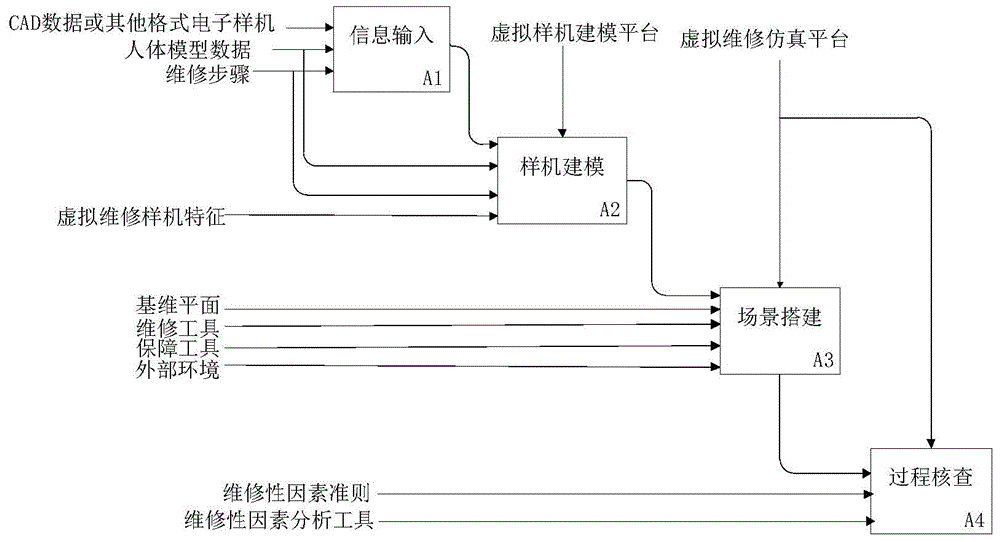

[0084] Taking the operation process of aircraft auxiliary power unit disassembly and maintenance as an example, the qualitative factors of maintenance safety that need to be considered in the whole process are considered and classified to form a hierarchical structure, and the weights of various factors relative to the factors of the previous level are analyzed. Various analysis tools in the environment obtain the evaluation results of single factors, and obtain their quantitative descriptions according to the classification of maintenance safety problems. Finally, the quantitative evaluation results of qualitative factors of maintenance safety are calculated step by step in combination with the weight vectors.

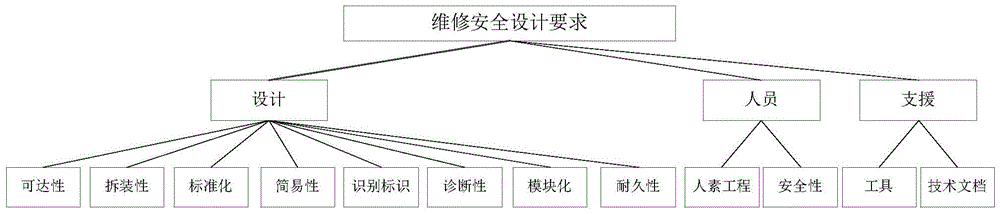

[0085] 1) Determination of qualitative factors of maintenance safety and division of hierarchical structure;

[0086] In the disassembly and maintenance process of aircraft auxiliary power unit, the main maintenance safety qualitative factors involved are considered as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com