Winder Workstation

A workstation and winding machine technology, applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc., can solve the problems of large wire tension peak, limit the speed of wire removal, and change of wire removal speed, etc., to achieve Efficiency improvement, removal speed improvement, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

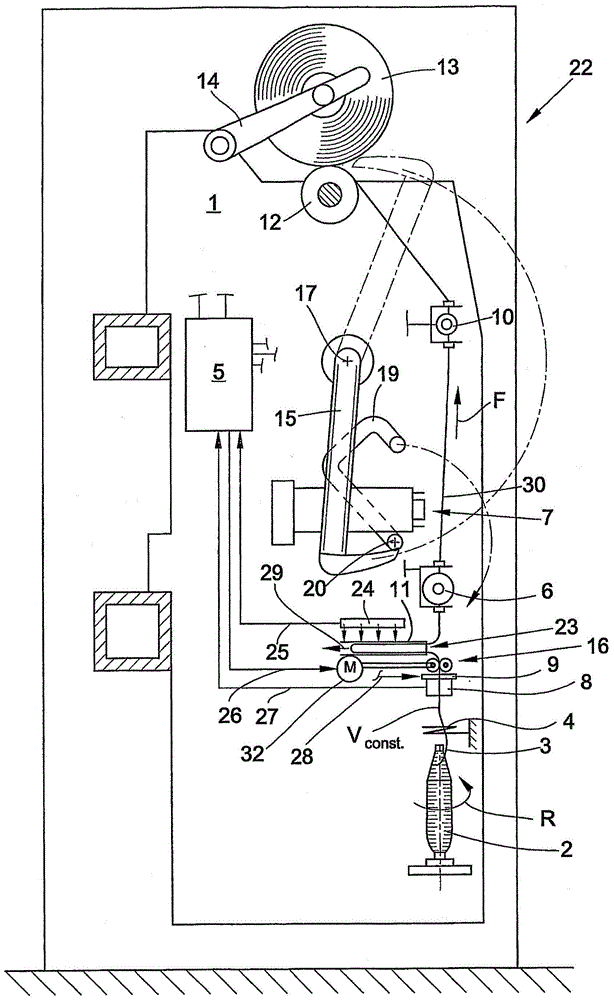

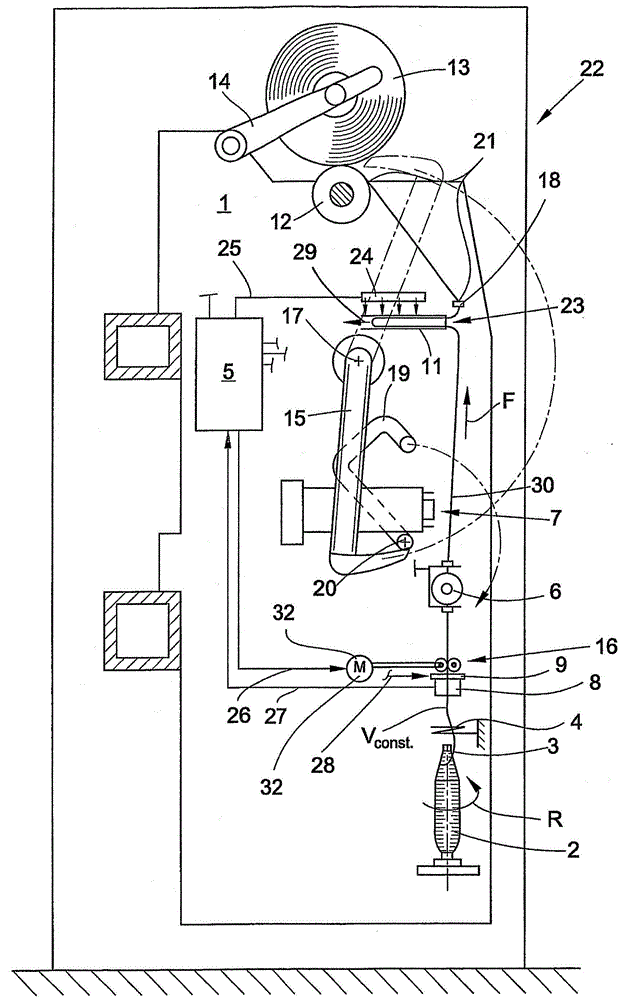

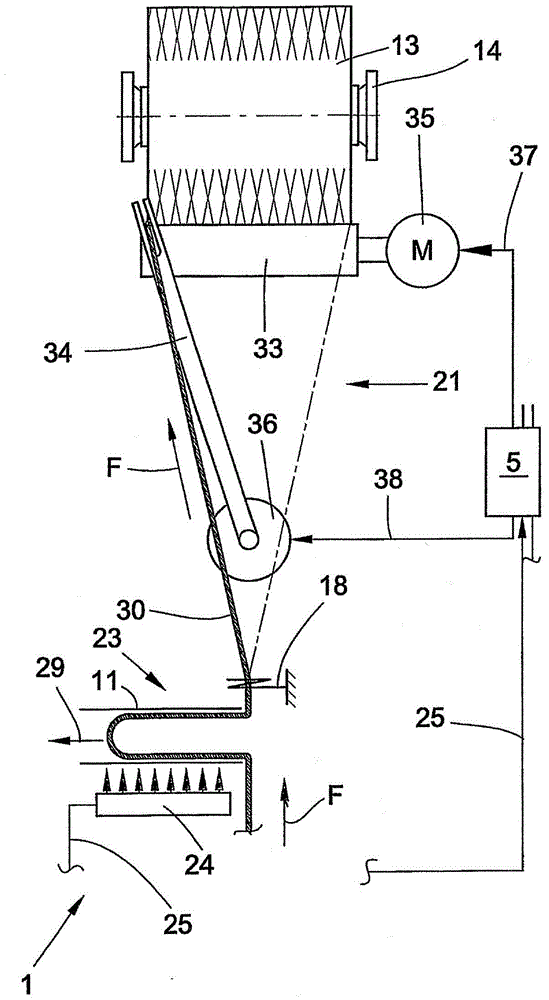

[0039] figure 1 , figure 2 and Figure 4 , Figure 5 Each of the workstations 1 of the automatic crosswinder 22 is shown schematically in side view. Such an automatic crosswinder 22 has a plurality of workstations 1 arranged side by side in a row between their end frames (not shown). Feed bobbins (usually spinning bobbins 2 ), produced for example on a ring spinning machine (not shown), are rewound at these stations or winders 1 to form high-capacity cross-wound bobbins 13 . For this purpose, the workstation 1 is equipped with various processing devices and thread inspection devices, which can be actuated in a defined manner respectively by the control device of the workstation itself, the so-called winder computer 5 . In other words, the workstation 1 has a winding device for producing cross-wound bobbins 13, a device 7 for pneumatically connecting thread ends after thread breakage or yarn clearer cutting, or other thread handling devices.

[0040] The winding device ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com