Maglev Train Bogie with Elevating Support Slider

A technology for magnetic levitation trains and bogies, which is applied to bogies, railway car body parts, transportation and packaging, etc., can solve the problems of damage to the traction motor 7, affecting the performance of the suspension system, and reducing the traction efficiency of the traction motor 7, so as to achieve high safety. reliability and reliability, the effect of guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

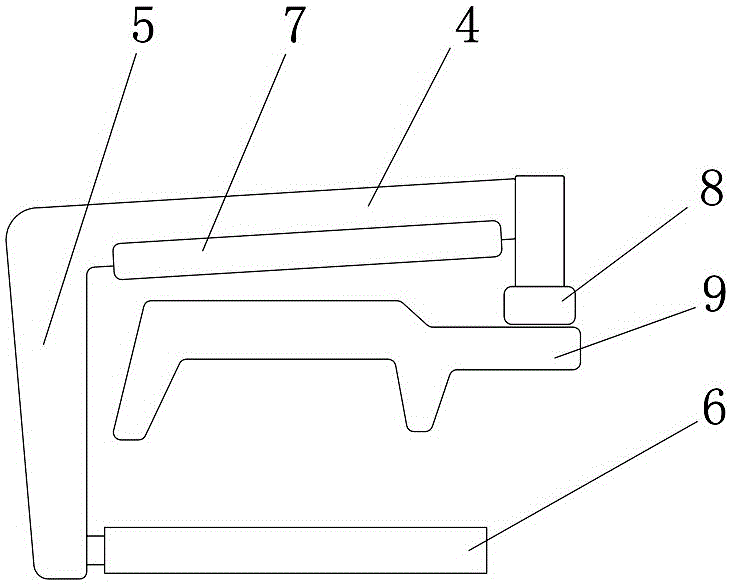

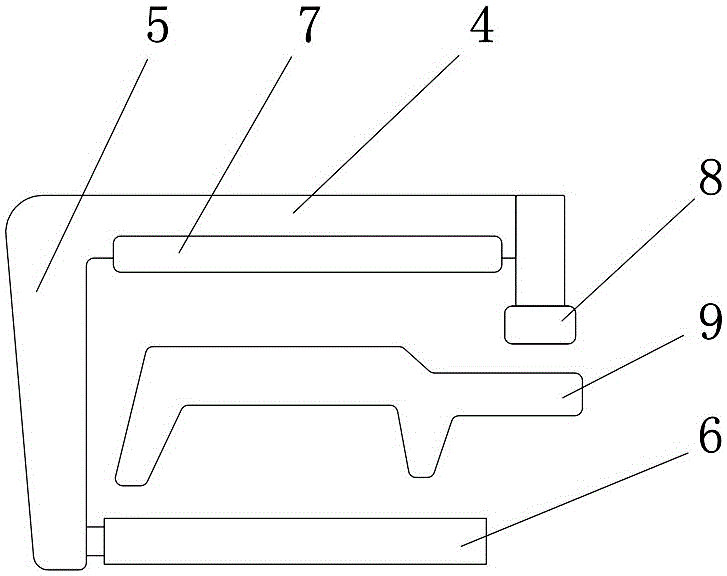

[0027] Figure 4 to Figure 7 It shows the first embodiment of the magnetic levitation train bogie with lifting support slider of the present invention, the magnetic levitation train bogie with lift support slider includes anti-roll beam group 3 and a pair of bogie modules 2, a pair of The bogie module 2 is connected through the anti-roll beam group 3. The bogie module 2 includes a box girder 4 and a support slider 8 for alighting and emergency braking. The support slider 8 is installed inside the box girder 4, and the support slider 8 An adjustment device 1 for adjusting the lifting of the support slider 8 is provided between the box beam 4. In this embodiment, the bogie module 2 also includes a support arm 5, an electromagnet 6 and a traction motor 7. The support arm 5 and the box girder 4 connection, the electromagnet 6 is installed on the support arm 5, the traction motor 7 is hung on the box girder 4, and the adjustment device 1 for adjusting the lifting of the support sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com