Rail-mounted omnidirectional rotation, agitation and pouring all-in-one machine

A rotary stirring, all-round technology, applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve the problems of unfavorable production site space, increased production costs, low work efficiency, etc., achieve simple structure and improve work efficiency , labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

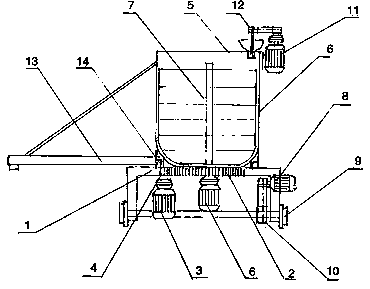

[0014] As shown in Figure 1, a rotary all-in-one mixing and pouring integrated machine includes a mixing tank 5 on the chassis 1 including four walking wheels, and a rotating gear ring 2 and a power output tooth on the motor 3 are set at the bottom of the mixing tank 5. The wheels 4 are meshed; the main power motor 4 is connected to the stirring shaft 7 at the center of the stirring bottom; the motor 8 is set on the four-wheel walking chassis, and the power output sprocket is connected to the main shaft sprocket chain on the track wheel 9; A batching motor 11 is arranged on the top, and the power take-off wheel is connected with the dial shaft wheel belt on the batcher 12; Several pulleys 14 intersect with the slide rail on the chassis 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com