Method and device for perforating a non-woven fabric by means of hydrodynamic needling

A non-woven fabric, hydrodynamic technology, applied in the direction of non-woven fabrics, needle punching machines, textiles and papermaking, etc., can solve problems such as difficult perforation, and achieve the effect of long durability and increased toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

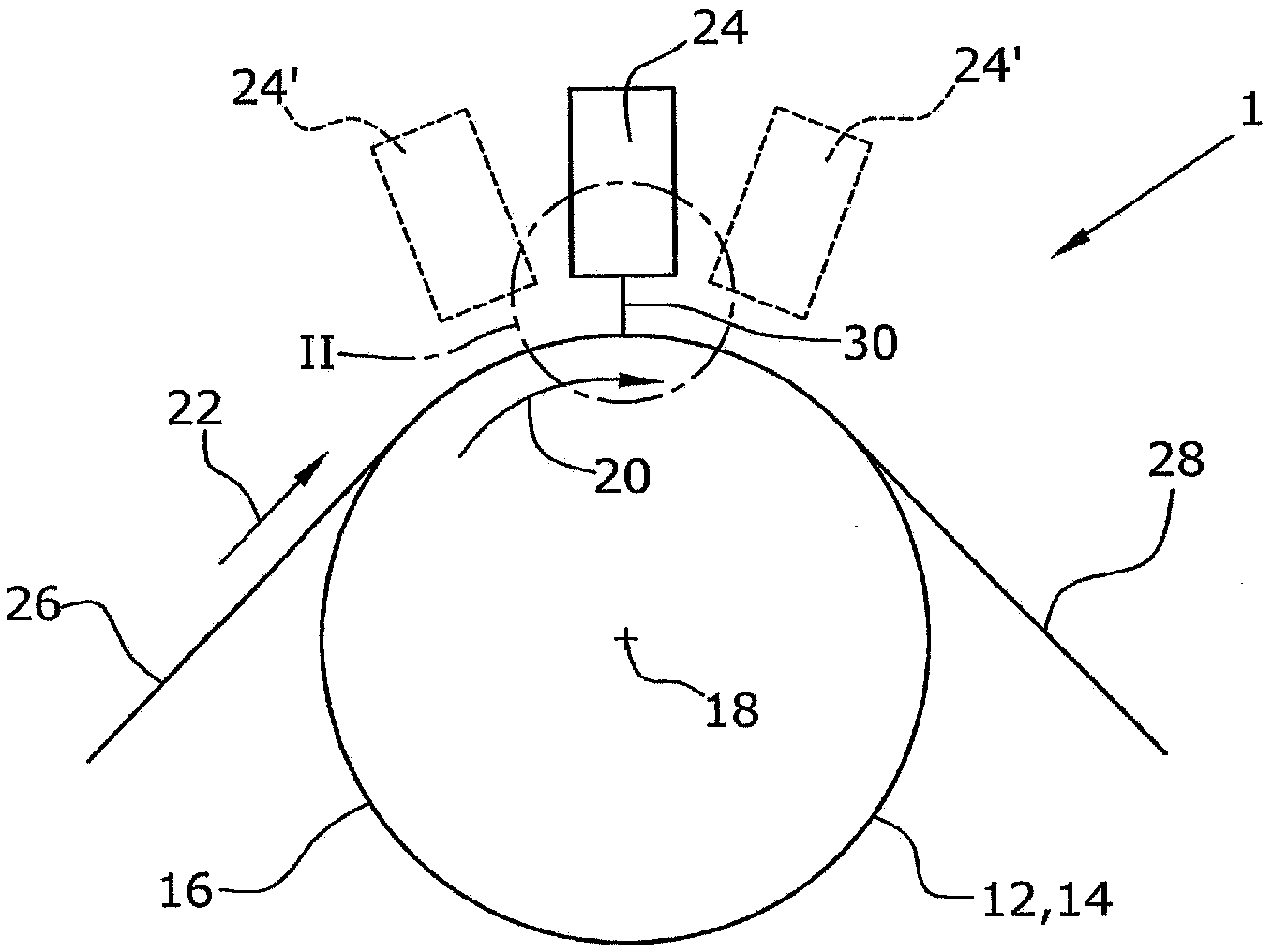

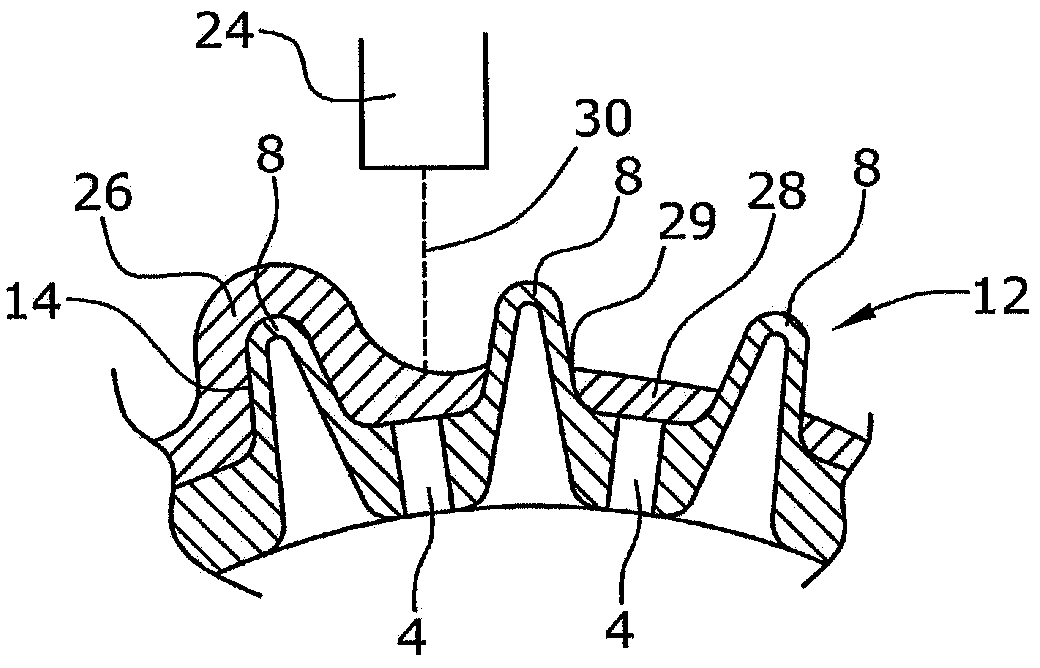

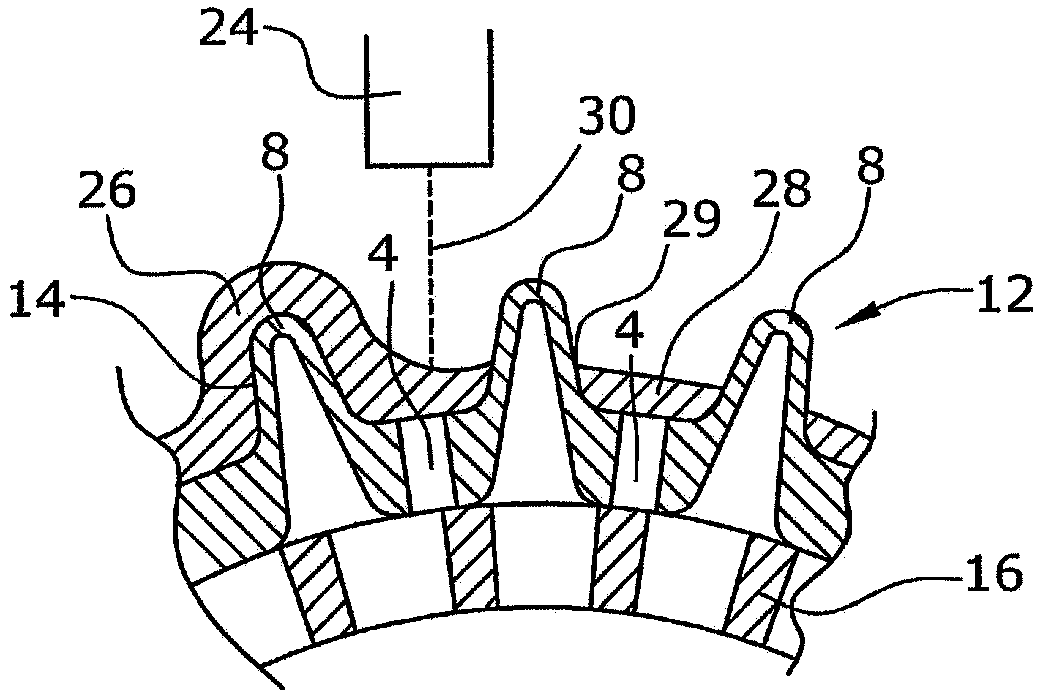

[0060] figure 1 A device 1 for perforating nonwoven fabrics 26, 28, 34 by means of hydrodynamic needle punching is shown. The device 1 includes at least one first support 12. The support 12 includes a support surface 14, wherein the first support surface 14 includes a first ridge 8 and a first perforation 4 as a drainage opening.

[0061] in figure 1 The support 12 shown in is the drum shell of the drum 16. On the support 12, a non-woven fabric 26 can be placed. By rotating the drum 16 about the axis 18 in the rotatable direction 20, the nonwoven fabric 26 can be conveyed in the conveying direction 22. The raised portion 8 and the perforation 4 are not in figure 1 Shown in. These in figure 2 The partial view is shown in more detail.

[0062] The first support can be realized as a self-supporting roller. Alternatively, the roller includes a base roller 16 with a first support 12 which is applied as an outer layer on the base roller. This is Figure 2a Shown in.

[0063] As ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com