A Bionic Compact Narrow Fertilizer Ditch Wide Seed Belt Ditch Opener

A compact, opener technology, used in planting methods, excavation/covering of trenches, shovels, etc., can solve problems such as over-wetting, uneven seeding depth, and inconsistent depth of assurance, to prevent entanglement and blockage, structural Compact and compact, the effect of reducing forward resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

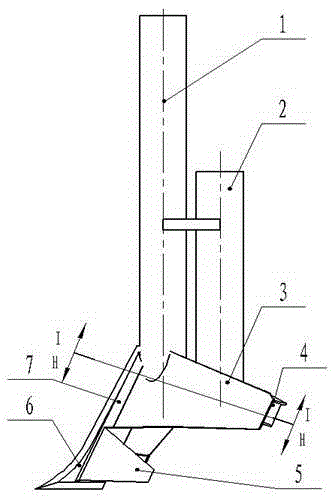

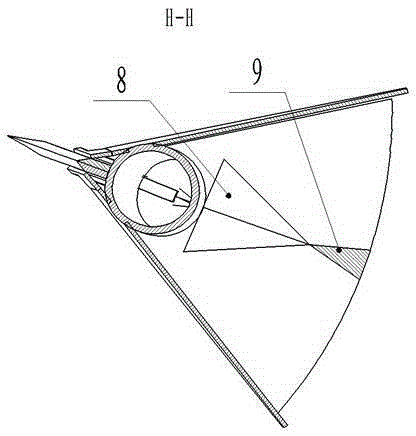

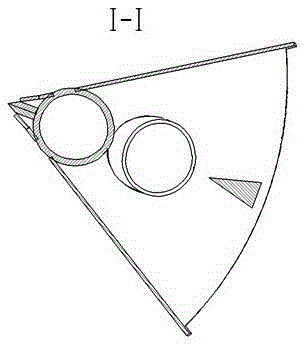

[0013] The entire opener is laid out around the fertilizer delivery pipe (l), and the seed delivery pipe (2) (welded together through the connecting plate), the seed distribution box (4), the narrow fertilizer ditch shovel wings (5), and the wide seed belt The shovel wing (3) and the excessive shovel wing (7) are welded into one body, the front lower part is inlaid with a sword-style front edge (6), and the narrow fat groove shovel wing (5) and the wide belt shovel wing (3) are welded on both sides and excessive shovel wings (7), the seed delivery pipe (2) and the seed distribution box (4) are welded together, and the fertilizer delivery pipe (l) is used as the shovel handle of the opener to connect and support the opener and the frame. The role is to bear the various forces that the opener is subjected to. The bottom of the fertilizer delivery pipe (1) is designed to be a long narrow rectangle to match the narrow fertilizer ditch shovel wings (5), so as to reduce the width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com