Winding device and winding method

A technology of winding device and winding method, which is applied in the direction of electromechanical devices, electrical components, manufacturing motor generators, etc., to achieve the effect of real stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

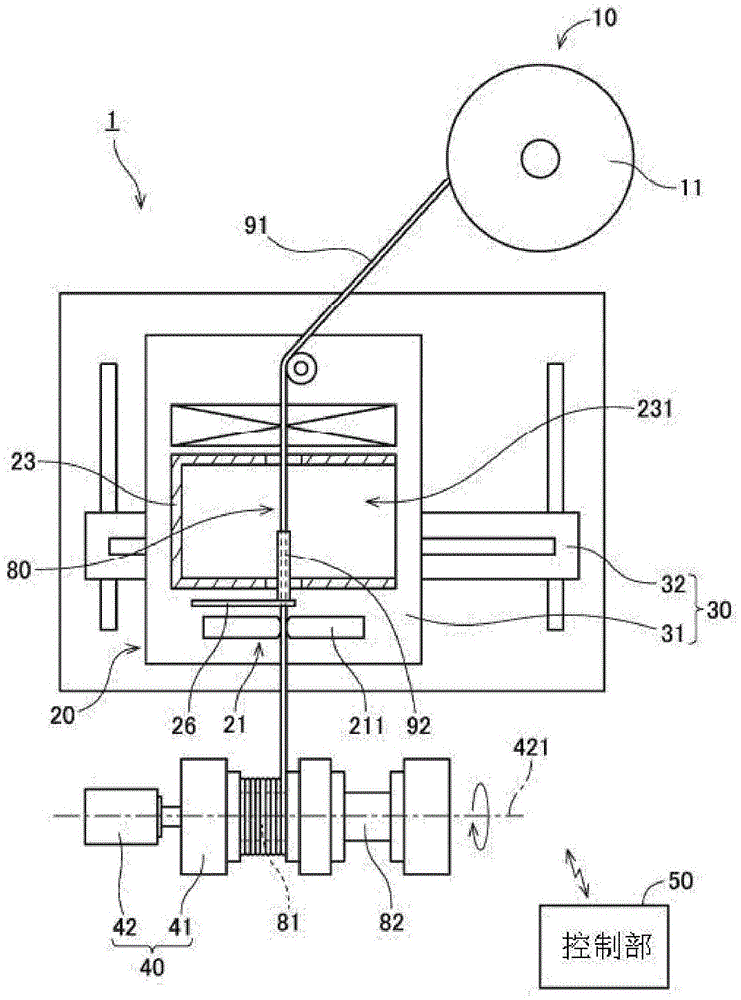

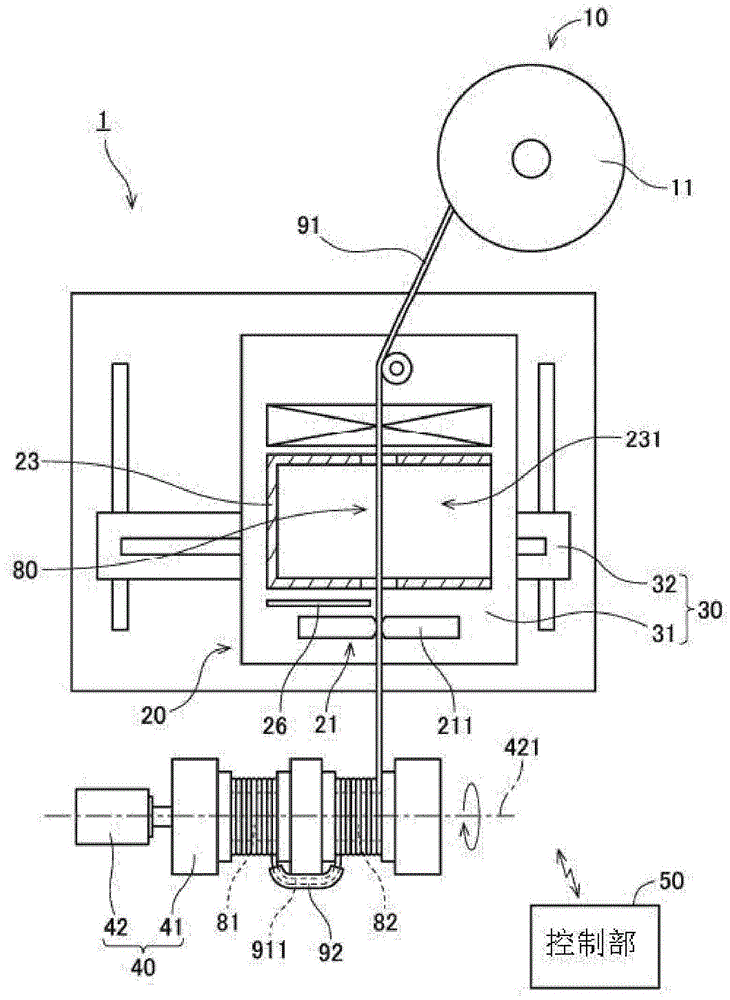

[0068] Next, the winding device 1 according to the second embodiment of the present invention will be described in detail.

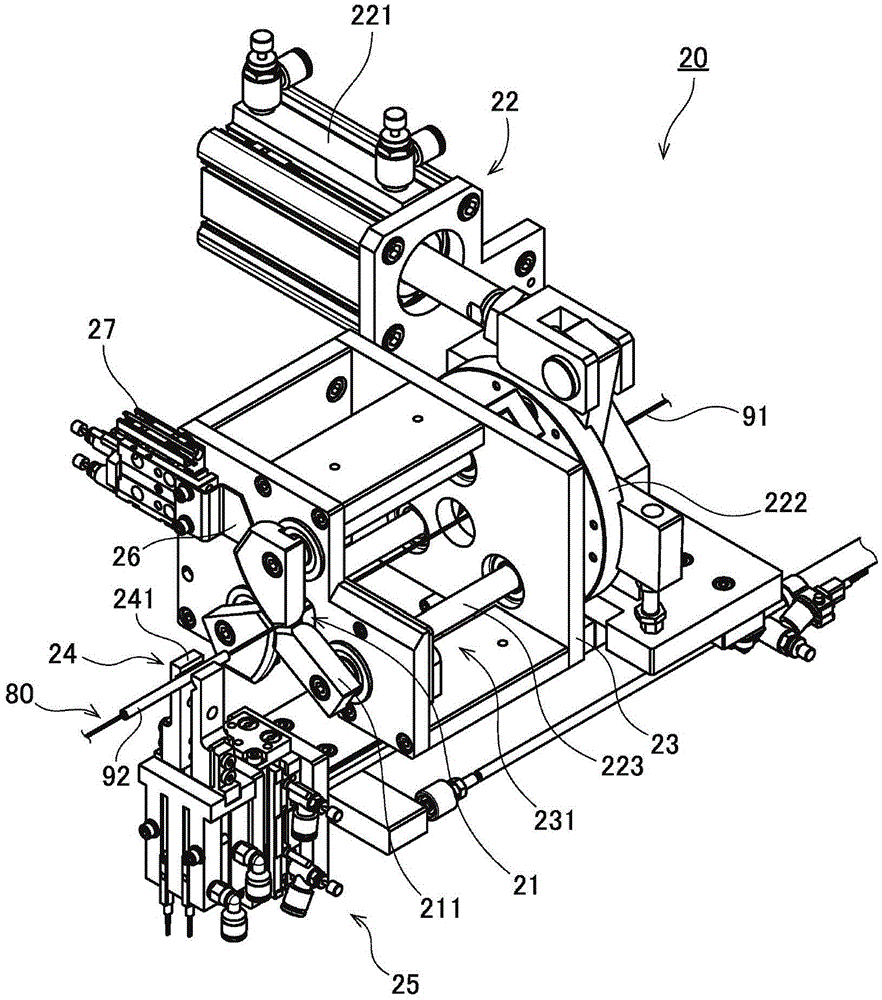

[0069] The insulating tube stopper 26 is a substantially plate-shaped member disposed between the guide portion 21 and the housing 23 . For example, metal such as iron is used as the material of the insulating tube stopper 26 . like Figure 8 As shown, the insulating tube stopper 26 of this embodiment extends horizontally from the vicinity of the supply path 80 along the surface of the housing 23 on the side of the guide portion 21 . and, if Figure 10 As shown, the insulating tube stopper 26 includes a plurality of walls 28 and a space 29 between the plurality of walls 28 . All of the plurality of wall surfaces 28 are opposed to the side surfaces of the conducting wire 91 .

[0070] In this embodiment, the insulating tube stopper 26 has a first wall surface 281 and a second wall surface 282 as the plurality of wall surfaces 28 . The first wall surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com