End bearing unit for spindle bearing device, spindle bearing device and textile machine

A technology of bearing device and end bearing, which is applied in the field of bearing devices for installing spindles and textile machines, can solve the problems of changing elastic characteristics and damping characteristics, complex and unfavorable spindle bearing devices, etc., to reduce waste, save structure and save energy. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

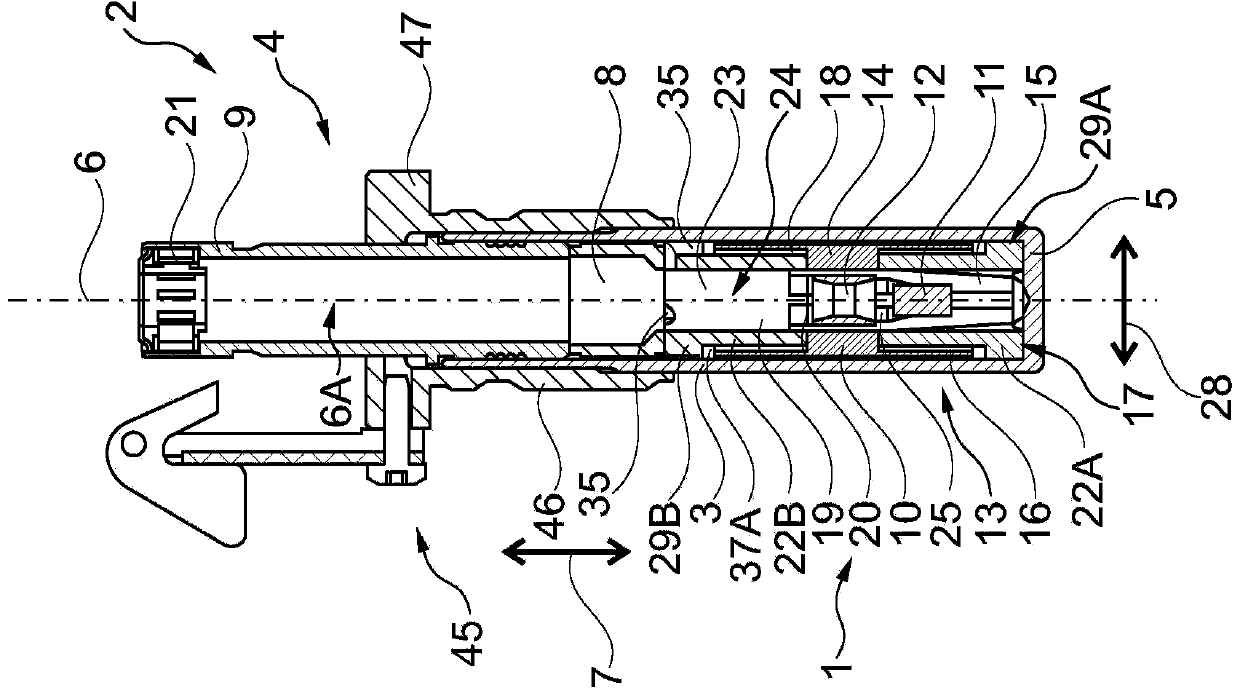

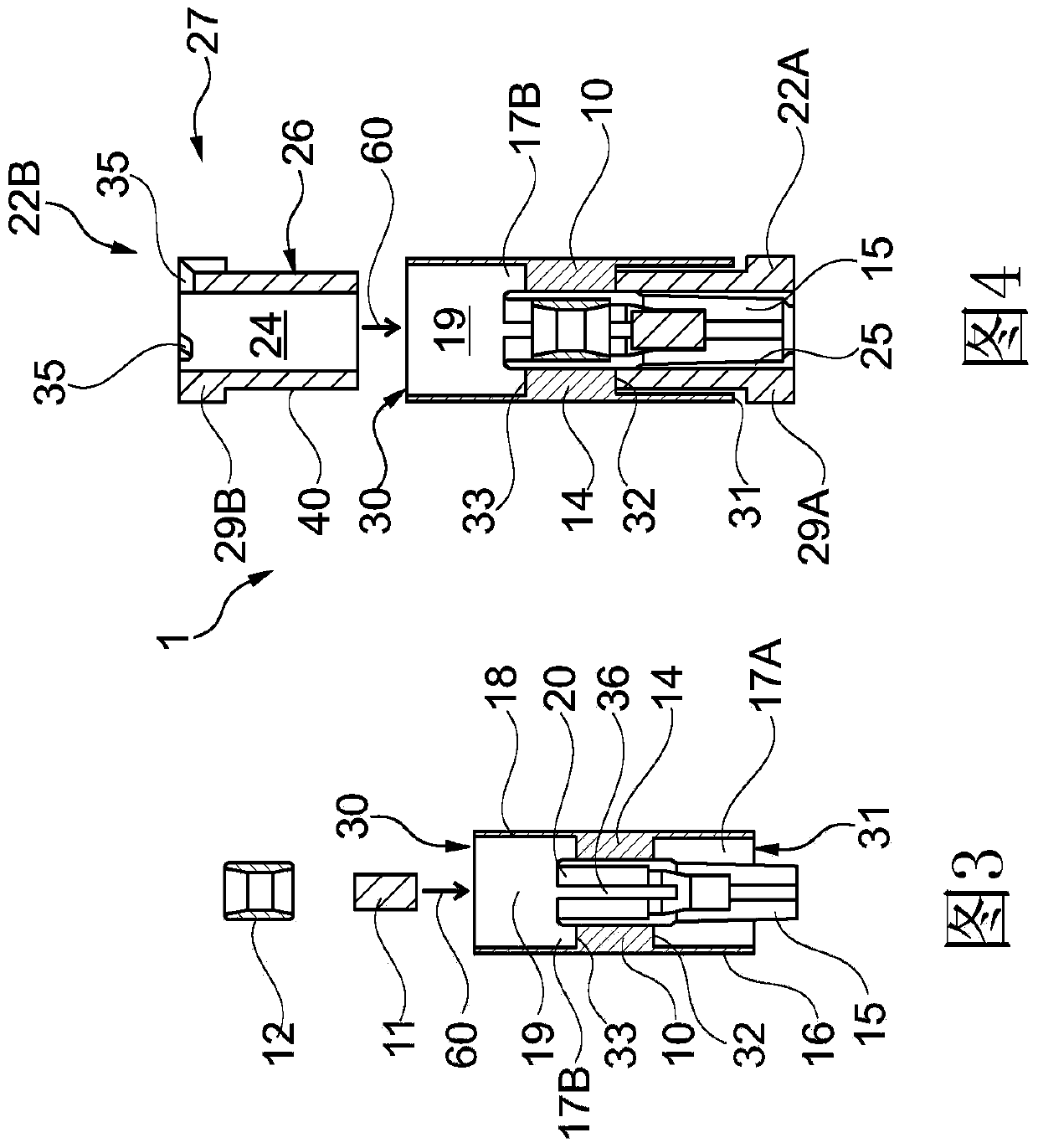

[0132] figure 1 and Figure 3 to Figure 7 The spindle bearing arrangement 2 shown in and equipped with an end bearing unit 1 according to the invention for mounting a spindle (not shown) has a housing sleeve 3, the end bearing unit 1 and the neck bearing unit 4 being at least partially arranged in in the casing sleeve.

[0133] On the one hand, the end bearing unit 1 is arranged on the bottom region 5 of the housing sleeve 3 , so that the end bearing unit 1 is fixed axially 7 on the bottom region 5 with respect to the center axis 6 of the spindle bearing arrangement 2 .

[0134] On the other hand, a spacer ring element 8 arranged between the end bearing unit 1 and the neck bearing unit 4 connects the end bearing unit 1 in the housing sleeve 3 . Since the neck bearing unit 4 is fixed such that it is pressed into the housing sleeve 3 , the spacer ring element 8 and the end bearing unit 1 are arranged axially fixed between the sleeve tube 9 and the bottom region 5 of the neck b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com