Automobile front auxiliary frame and corresponding automobile

A front sub-frame and automobile technology, applied to vehicle parts, substructure, transportation and packaging, etc., can solve the problem of high cost, achieve the effect of lightweight structure, simple cross-section design, and reduce process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

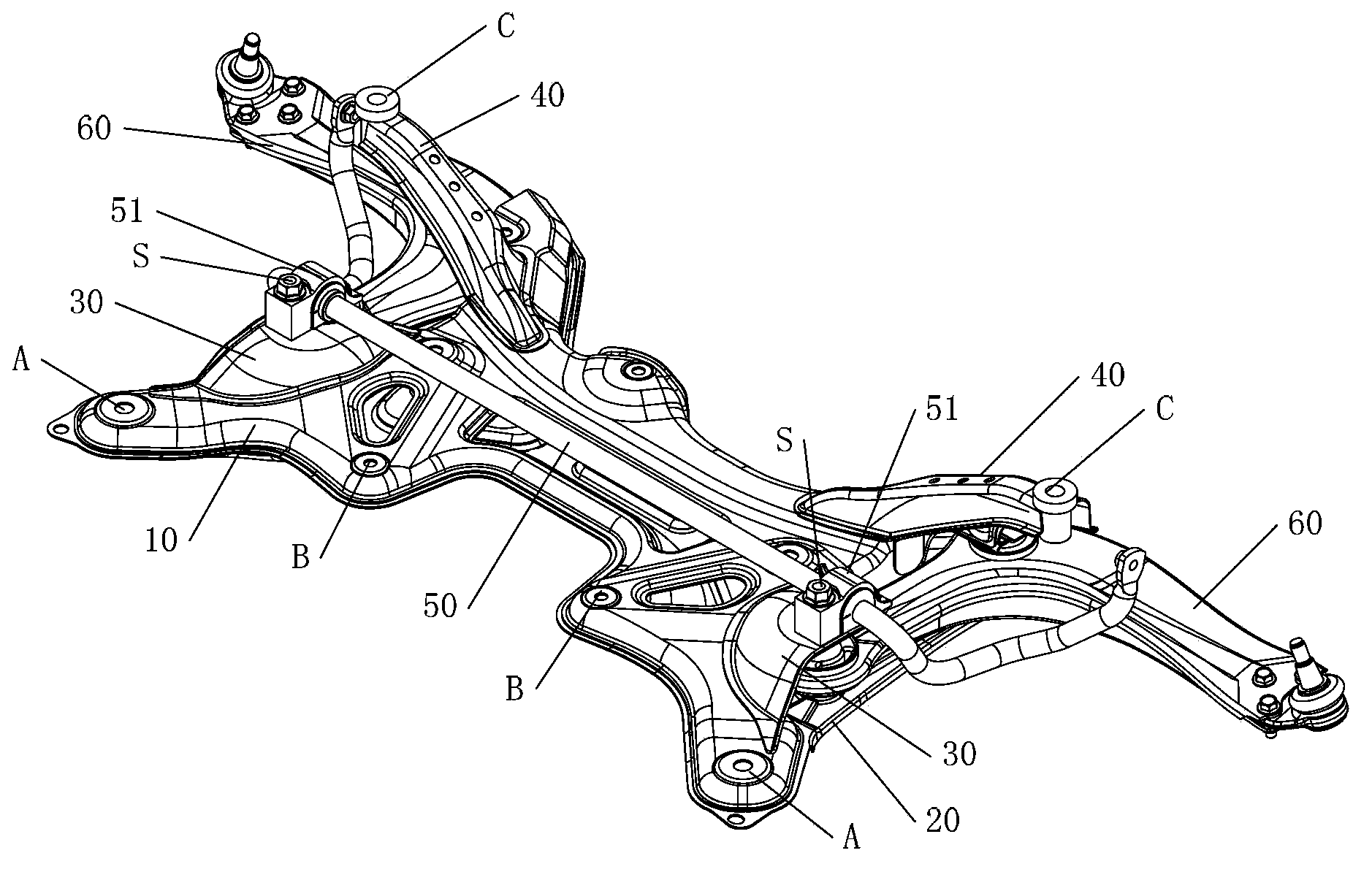

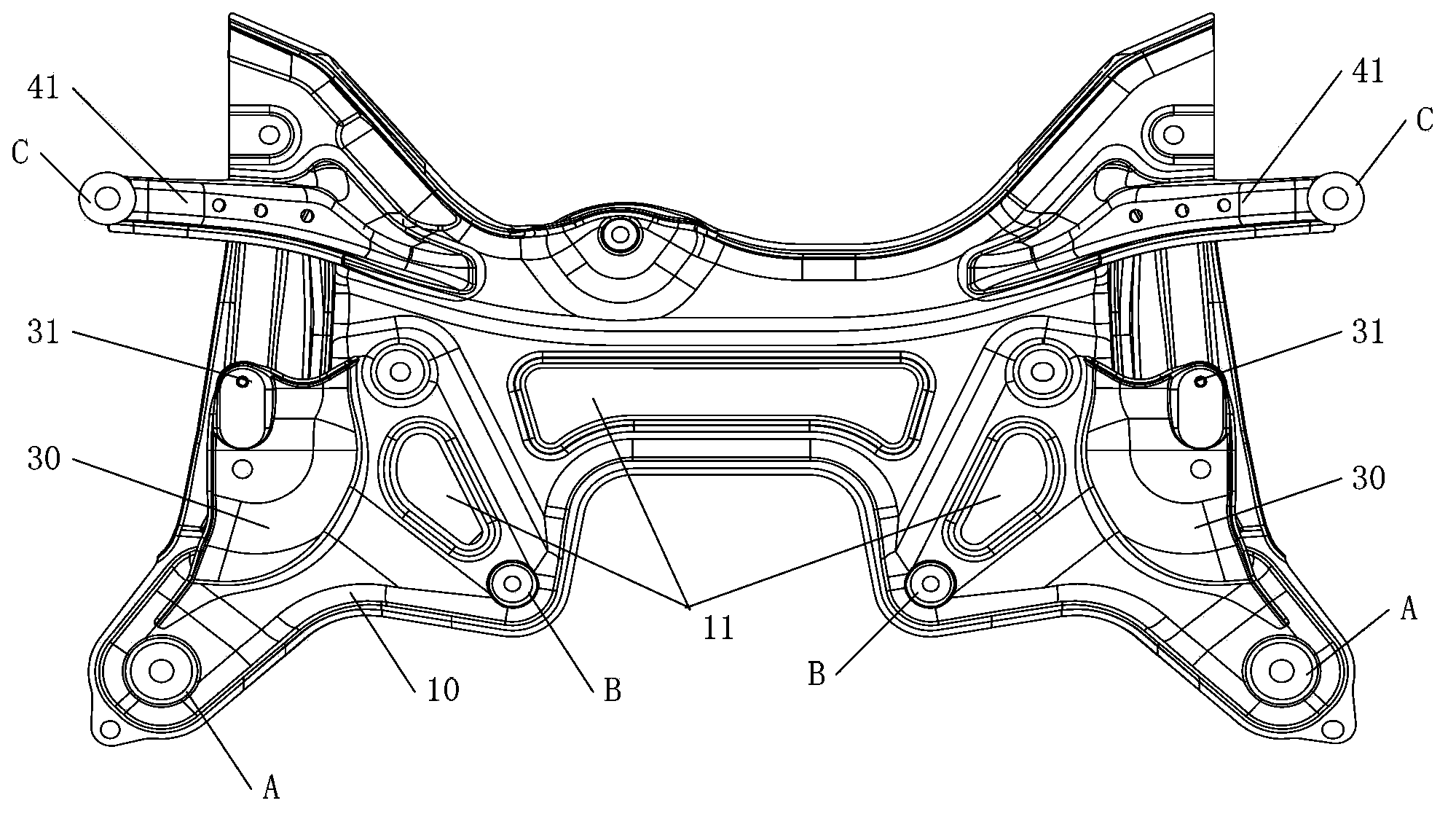

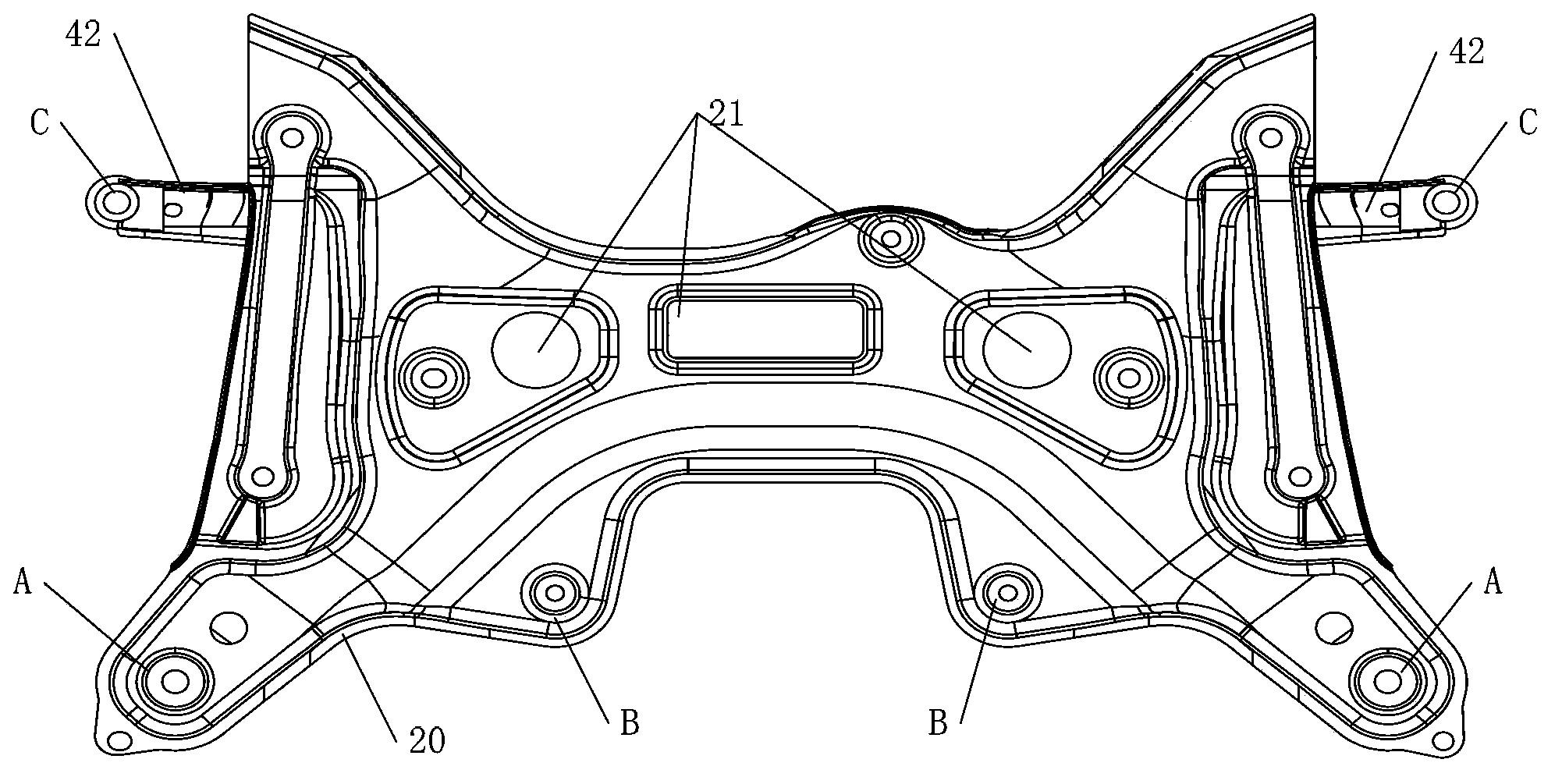

[0030] like figure 1 , figure 2 , image 3 and Figure 4 As shown, in order to realize the purpose of structural optimization and lightweight design, the present invention provides a kind of automobile front sub-frame, comprises the front sub-frame upper board 10 and the front sub-frame lower board 20 that are mated with each other, wherein the front sub-frame Both sides of the upper plate 10 of the frame are respectively provided with a stabilizer bar mounting plate 30, and each stabilizer bar mounting plate 30 is provided with a mounting hole 31 for installing the stabilizer bar 50 (such as figure 2 and Figure 4 shown), and the space between each stabilizer bar mounting plate 30 and the front sub-frame lower plate 20 is suitable for placing one end of the swing arm 60, so that one end of the swing arm 60 and the stabilizer bar 50 pass through a common fastener S (such as a bolt ) through the mounting hole 31 for installation.

[0031] In this embodiment, the stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com