Device for scattering straight rice noodles by rubbing

A technology of straight rice noodles and rice noodles, which is applied in baking, food forming, food science, etc., can solve the problems of workers in humid production environment, prone to occupational diseases, and high labor intensity, so as to reduce the broken rate of rice noodles and achieve ideal results , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

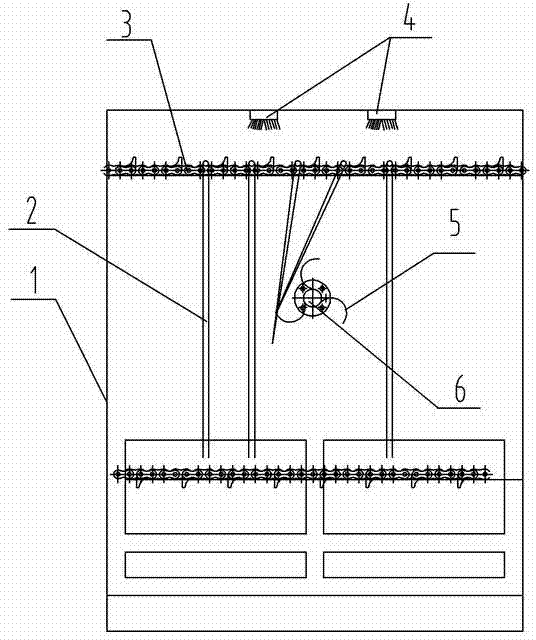

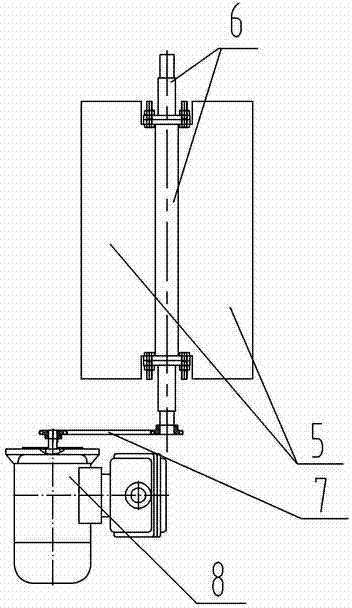

[0010] A straight rice noodle rubbing device, comprising a box body 1, a motor 8, a conveying chain 3, and a rice noodle hanging rod, is characterized in that the inside of the box body 1 is a cavity, and the two sides of the box body 1 are respectively provided with a conveying chain 3, and the rice noodle hanging rod The rod is evenly placed on the conveying chain 3, the rice noodles 2 are hung on the rice noodle hanging rod, and a rubbing machine is installed under the rice vermicelli hanging rod in the box 1, and the rubbing machine is composed of a bearing seat, a bearing, a rotating shaft 6, a flange, and an arc plate 5 The arc-shaped plate 5 is connected to the rotating shaft 6 through the flange, and three arc-shaped plates 5 are evenly installed on the rotating shaft 6. The output shaft is connected, and the top of the casing 1 above the rubbing machine is provided with a water nozzle 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com