Reliability degree predication method for composite material based on fatigue life distribution

A composite material, fatigue life technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of unsuitable composite material test data dispersion, large calculation amount, unfavorable engineering operation, etc., and achieve technical characteristics Simple, physically meaningful, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

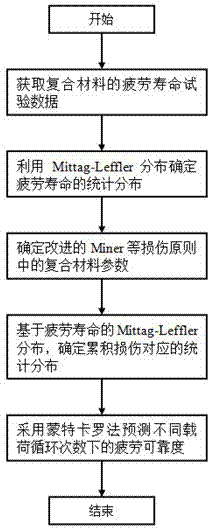

Method used

Image

Examples

Embodiment 1

[0061] (1) The present invention takes the unidirectional carbon / epoxy composite material as an example for axial pull-pull loading on the AMSLER10HFP1-478 high-frequency fatigue machine produced in Switzerland, and the sample size of the fatigue life data is 50 (see: the data comes from Document 2 Xu Renping. Research on fatigue life data of composite materials [J]. Material Development and Application, 9,18-21,1994).

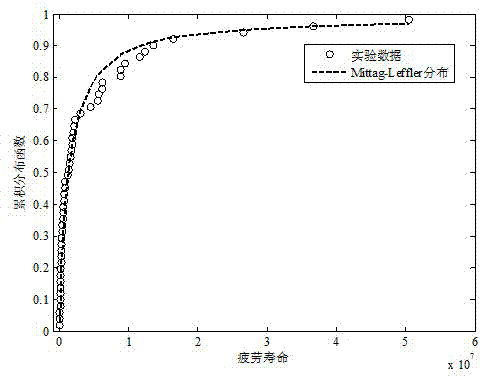

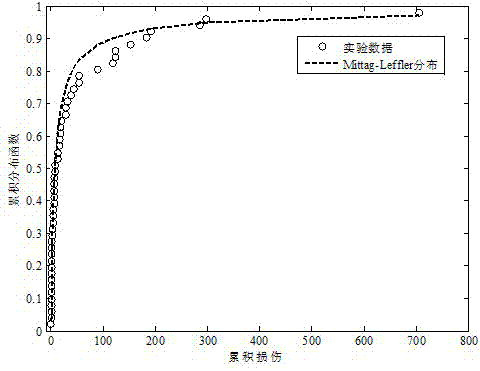

[0062] (2) See figure 2 As shown, the cumulative distribution function of the Mittag-Leffler distribution is used to simulate the cumulative distribution of fatigue life of unidirectional carbon / epoxy composites. First, the value of the scale parameter σ of the Mittag-Leffler distribution is determined by fractional moment estimation, and then the value of the stability index α is estimated by the least square method, as shown in Table 1.

[0063] Table 1 Stability index α and scale parameter σ corresponding to Mittag-Leffler distribution

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com