Mass-type rock soil wetting-drying cyclic experiment apparatus and experiment method

A dry-wet cycle and experimental device technology, applied in the field of geotechnical engineering, can solve the problems of low degree of automation, heavy manual labor, long time-consuming dry-wet cycle test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

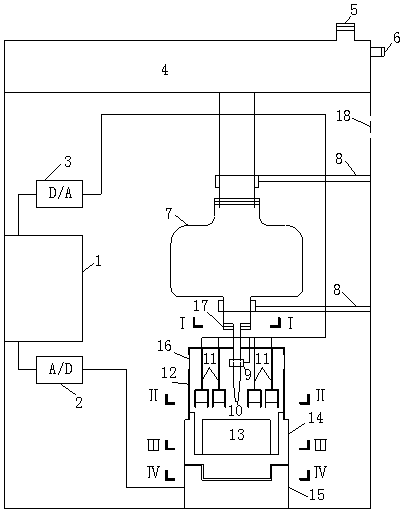

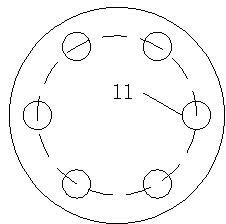

[0031] The drying device includes a drying lamp 11, a lampshade 12 and a base 14, the drying lamp 11 is fixed on the inner wall of the lampshade 12, the lampshade is fixed on the base 14, the sample 13 is placed on the base 14, and the drying lamp is arranged directly above the sample 13 .

[0032] The weighing device is a weighing platform, and the base 14 of the drying device is connected above the weighing platform 15 .

[0033] The casing 18 is provided with a connecting plate 8, and there are two connecting plates arranged at the upper and lower ends of the water storage 7 for fixing the water storage 7. Wherein, the water storage tank 4 is a large-capacity water tank, the top has a water inlet, and the water inlet is connected to a water source; the upper part of the water storage tank 4 and the side of the water inlet are provided with an overflow port, which is used for overflowing when there is too much water in the water storage tank 4. Flow, the overflow port is ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com