Car light testing fixture with separation and integration functions

A technology of inspection tools and inspection tools for car lights, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, machines/structural components, testing, and measuring devices. Achieve the effects of highlighting substantive features, reducing deformation damage, and reducing the cost of inspection tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

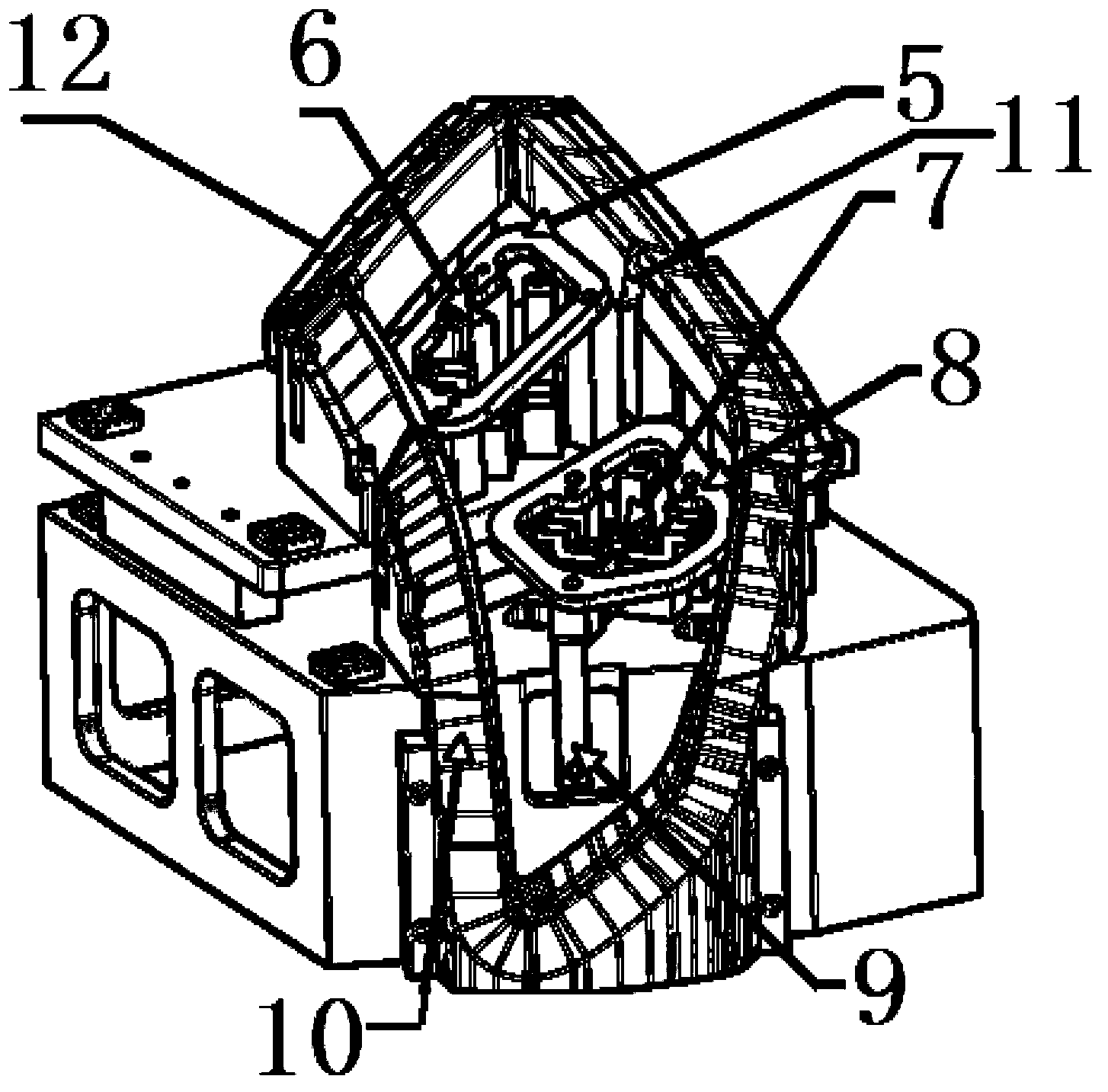

[0025] The first checker main body 4 includes a profile 10 for detecting lamp A that imitates the contour of the vehicle body, and a fixing bracket for detecting lamp A that prevents the structure of the vehicle body. The profile 10 for detecting lamp A is connected to the fixing bracket for detecting lamp A. The second checker main body 2 includes a profile 12 for detecting a B lamp that imitates the outline of a vehicle body, and a fixed bracket for detecting a B lamp that prevents the structure of the vehicle body.

[0026] In general, the fixed bracket for A lamp detection includes waterproof ribs 8 for A lamp detection against body waterproof ribs, positioning sheet metal for A lamp detection against body sheet metal, profiles 10 for A lamp detection, and waterproof ribs 8 for A lamp detection. Connect to the positioning plate 9 for lamp A detection. The fixed bracket for B lamp detection includes waterproof ribs 5 for B lamp detection against body waterproof ribs, positi...

specific Embodiment 2

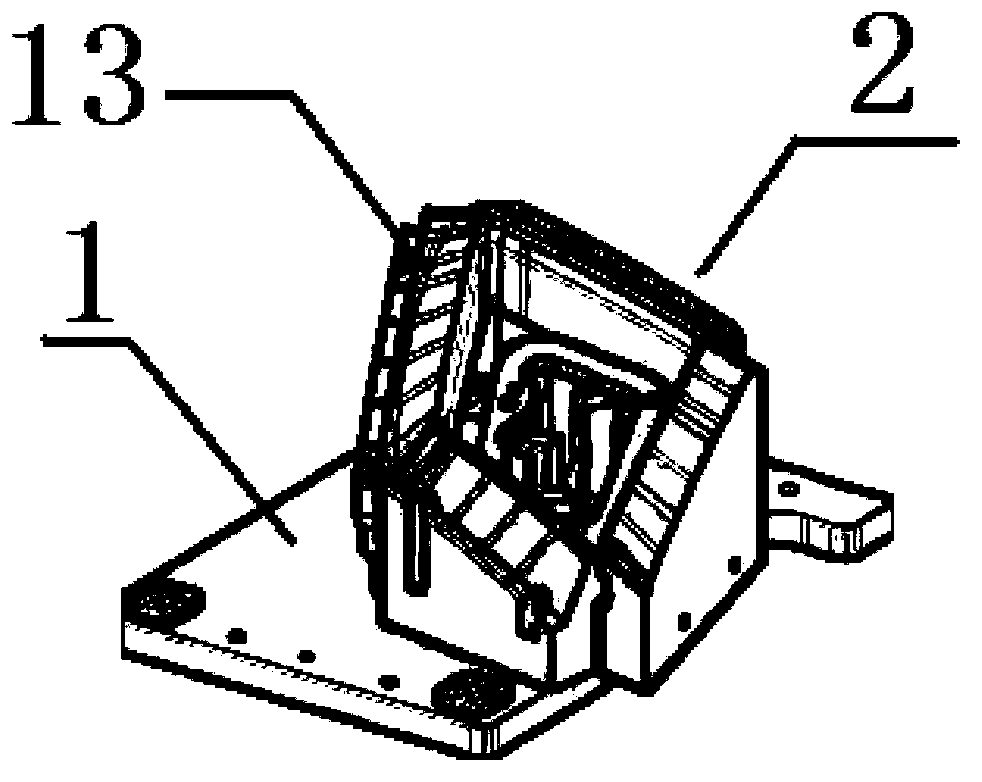

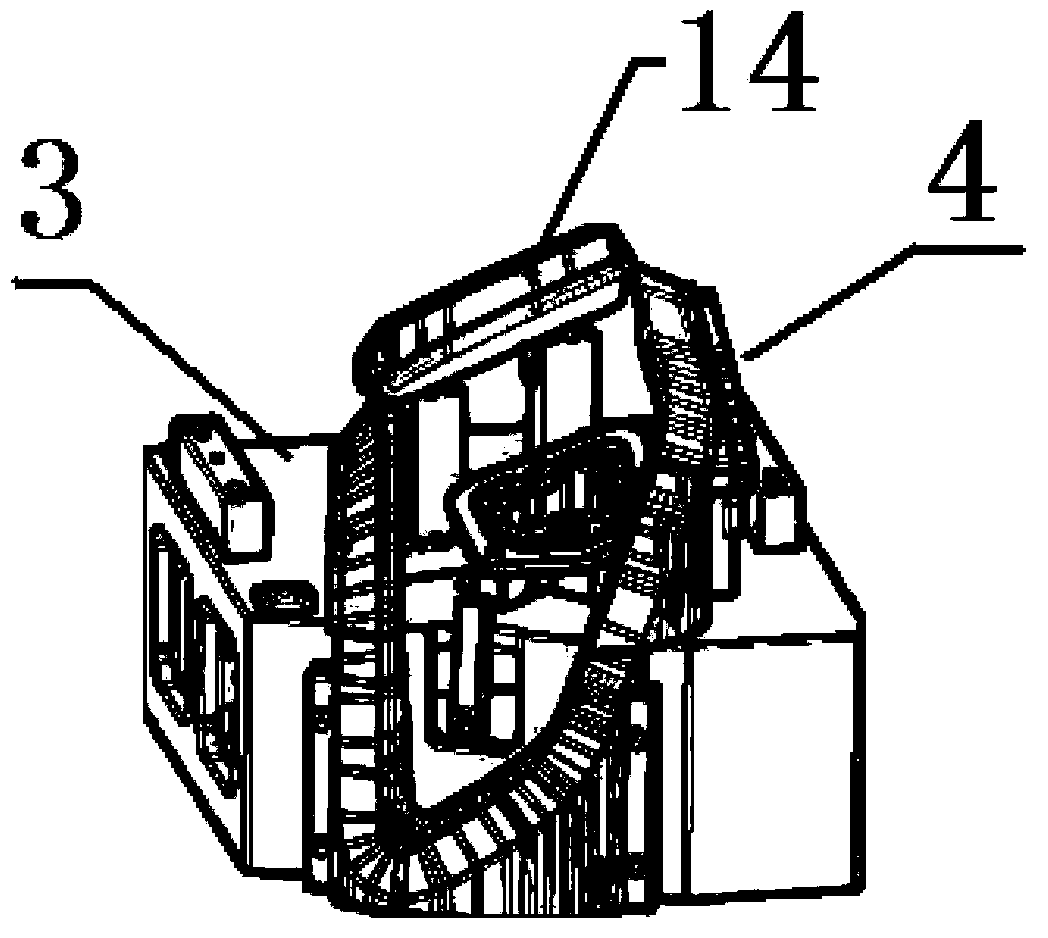

[0028] On the basis of the specific embodiment 1, the main body 4 of the first inspection tool 4 is also provided with an auxiliary part 14 for the detection of the A lamp at the opening of the profile 10 for the detection of the A lamp, and the auxiliary part 14 for the detection of the A lamp is detachably connected to the first inspection device. Tool base 3. The second inspection fixture main body 2 is also provided with an auxiliary part 13 for B lamp inspection at the opening of the profile 12 for B lamp inspection, and the auxiliary part 13 for B lamp inspection is detachably connected to the base 1 of the second inspection fixture. A detachable connection is adopted between the auxiliary parts and the base of the inspection fixture. After the auxiliary parts are assembled, the overall inspection of a single lamp can be completed. After the auxiliary parts are disassembled, the overall shape of the two profiles after assembly is guaranteed to be consistent with that of t...

specific Embodiment 3

[0029] On the basis of specific embodiment 1 and specific embodiment 2, any one of the first checking tool base 3 and the second checking tool base 1 is used as a supporting base, and the other is used as a supported base, and the supported base sits on the supporting base, The supported base presses the supporting base under the action of gravity, thereby completing the combination of the first checking tool base 3 and the second checking tool base 1 .

[0030] The supporting base includes a fixing platform for fixing the main body of the checking tool, and a fixing platform for the checking tool base used to connect the supported base. The two fixing platforms are arranged side by side. area.

[0031] Because the lamp A located on the outer side occupies a larger space than the lamp B located on the inner side, and has a higher height, it is preferable that the first inspection tool base 3 is a supporting base. The area of the fixture base fixing table is higher than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com