Novel connecting rod

A connecting rod and a new type of technology, applied in the field of connecting rods, can solve the problems of increasing the cost of the support rod, reducing the utilization rate of the support rod, and being unable to be used in general, and achieving the effects of improving the utilization rate, easy production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

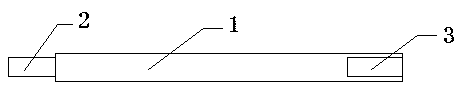

[0016] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0017] Such as figure 1 Shown: a new connecting rod, including a rod body 1 and a rod head 2, the rod head 2 is located at the head of the rod body 1, and is integrally formed with the rod body 1, and the tail of the rod body 1 is also provided with a socket 3, The cross-section of the insertion hole 3 is consistent with the cross-sectional shape and size of the rod head 2 .

[0018] In this embodiment, the length of the socket 3 may be the same as that of the rod head 2, and the cross-sectional shapes of the rod body 1 and the rod head 2 are the same, and the cross-sections of the rod body and the rod head are both round.

[0019] Of course, the length of the socket 3 can also be different from the length of the rod head 2, and the cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com