Coal Mine Wet Concrete Shotcrete Technology

A concrete spraying machine and concrete technology, which is applied to shaft lining, underground chambers, mining equipment, etc., can solve the problems of difficult control of concrete quality, damage to miners' health, and matching of shotcrete technology, achieving remarkable environmental protection effects and eliminating dust. hidden dangers and the effect of ensuring the quality of shotcrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the utility model is further described:

[0036] A coal mine underground wet concrete spraying process, comprising the following steps:

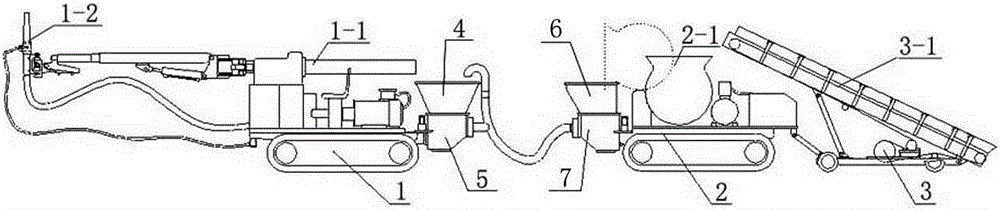

[0037] 1. Mechanized spraying line

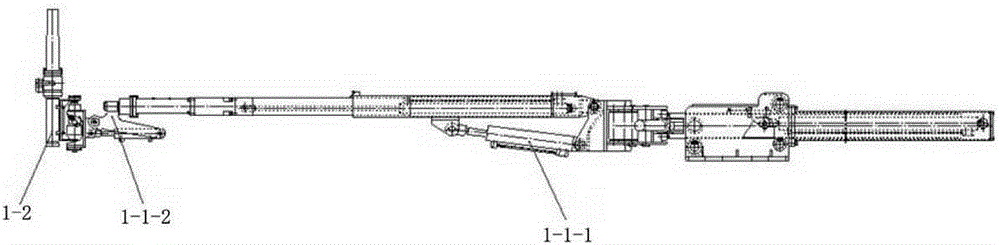

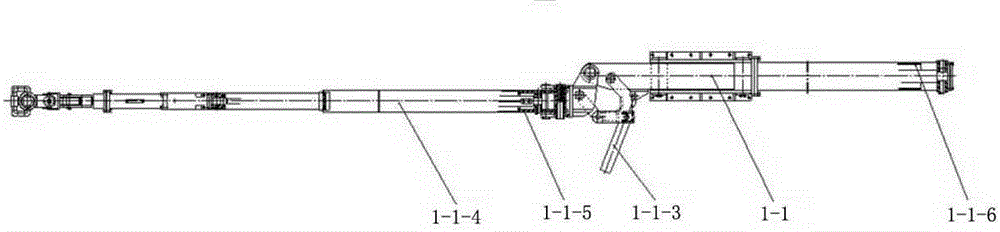

[0038] Such as figure 1 As shown, the mechanized spraying line includes a crawler-type movable wet concrete sprayer 1, a crawler-type movable mixing station 2, a rubber-wheeled movable belt feeder 3; The wheel-type movable belt feeder 3 sends the prepared dry material to the mixing hopper 2-1 of the crawler-type movable mixing station 2, and adds water to the mixing hopper 2-1 for stirring, and then puts the mixing hopper 2-1 The wet concrete is transported to the first pumping hopper 4 of the crawler-type movable wet-type concrete sprayer 1, and pushed to the crawler-type movable wet-type concrete sprayer by the first pumping system 5 of the crawler-type movable wet-type concrete sprayer 1. Spray gun 1-2 of machine 1, use compressed air with liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com