Method for winding coil of three-phase motor

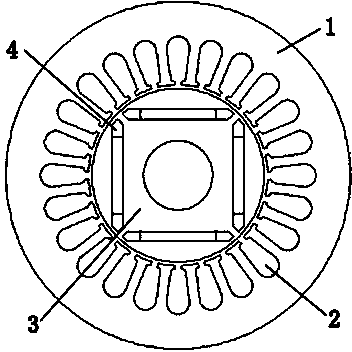

A technology of three-phase motor and winding method, which is applied in the field of coil winding of three-phase motors, can solve problems such as difficulty in realizing low noise, large deviation of sine wave distribution, and unsatisfactory excitation distribution, and achieve simple manufacture, stable operation, Effect of reducing motor vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

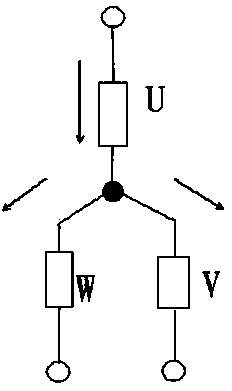

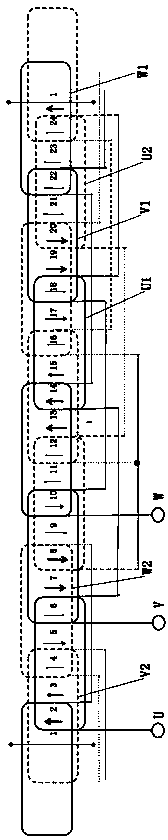

[0034] like image 3As shown, a coil winding method for a three-phase motor, the first phase coil group U is introduced from the first slot, drawn from the sixth slot to the thirteenth slot, and then introduced from the thirteenth slot, from the tenth The eighth wire slot is drawn to the twenty-fourth wire slot to form the winding U1, and then the reverse lead is introduced from the twenty-fourth wire slot, drawn from the nineteenth wire slot to the twelfth wire slot, and then introduced through the twelfth wire slot, from The seventh wire slot is connected to the neutral point of the Y-connection to form the winding U2;

[0035] The second phase coil group V is introduced from the fifth wire slot, drawn from the tenth wire slot to the seventeenth wire slot, and then introduced through the seventeenth wire slot, and drawn out from the twenty-second wire slot to the fourth wire slot to form winding V1 , and then the reverse lead is introduced from the fourth wire slot, drawn f...

Embodiment 2

[0041] like Figure 4 As shown, a coil winding method for a three-phase motor, the first phase coil group U is introduced from the first slot, drawn from the seventh slot to the thirteenth slot, and then introduced from the thirteenth slot, from the tenth The nine wire slots are connected to the first wire slot to form the winding U1, which is introduced from the twenty-fourth wire slot, drawn from the sixth wire slot to the twelfth wire slot, and then introduced from the twelfth wire slot, and then from the eighteenth wire slot The central point connected to the Y-shaped connection and the twenty-fourth slot are drawn out respectively to form the winding U2, and the initial lead-in ends of the two windings are connected;

[0042] The second phase coil group V is introduced from the fifth wire slot, drawn from the eleventh wire slot to the seventeenth wire slot, then introduced from the seventeenth wire slot, drawn out from the twenty-third wire slot and connected to the fifth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com