Verification test device and method for active control device of spacecraft structure potential

A technology of potential active control and spacecraft structure, which is applied in the direction of electrical testing/monitoring, etc., can solve the problems that the effect of this kind of technology cannot be guaranteed, spacecraft verification test devices and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

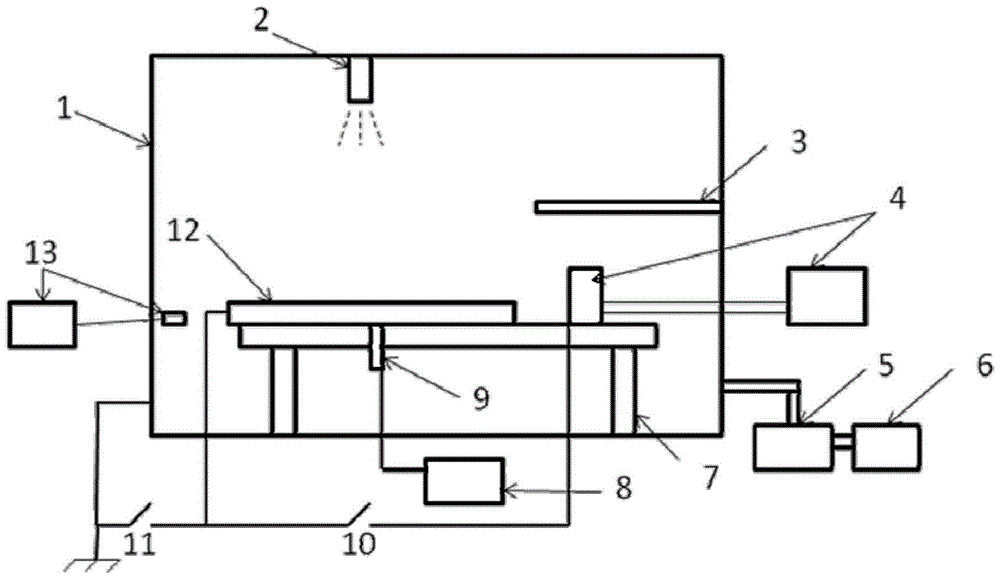

Image

Examples

Embodiment approach

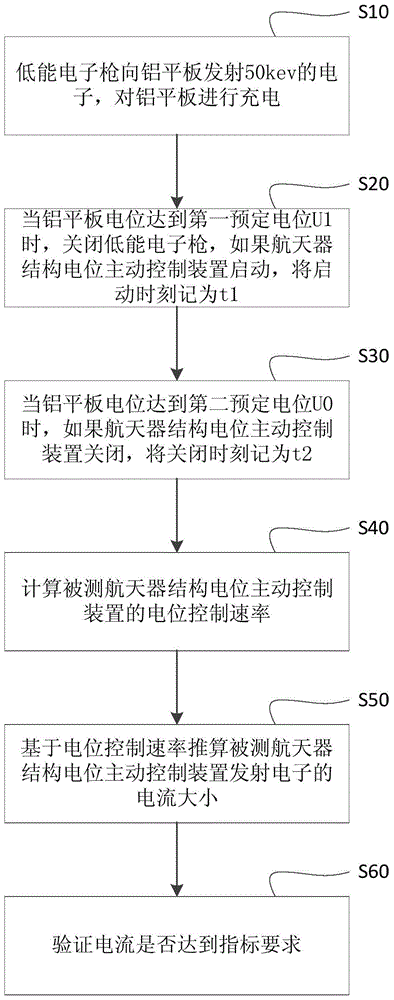

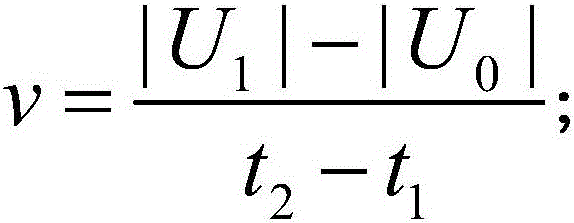

[0056] As an implementation, the verification test method based on the verification test device of the spacecraft structure potential active control device may also include:

[0057] S70: Turn on the low-energy electron gun 2 again, and monitor the potential change of the aluminum plate 12 through the potential monitoring module within a predetermined time.

[0058] Through this step, the point-holding ability of the measured spacecraft structure potential active control device can be verified.

[0059] As an implementation manner, before step S10, the verification test method may also include:

[0060] closing the second switch 10;

[0061] Open the vacuum gauge 13 and the vacuum mechanical pump 6, so that the vacuum chamber air pressure drops below 1Pa;

[0062] Turn on the vacuum molecular pump 5 so that the vacuum chamber 1 pressure drops to 1×10 -4 Pa.

[0063] In this way, the vacuum state in the vacuum chamber 1 can be guaranteed before starting the verification tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com