A water inlet channel of a pump body

A technology of water inlet flow channel and pump body, which is applied in the direction of pumps, pump components, non-variable pumps, etc., and can solve problems such as increased NPSH, unsuitable rectangular inlets, and decreased efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

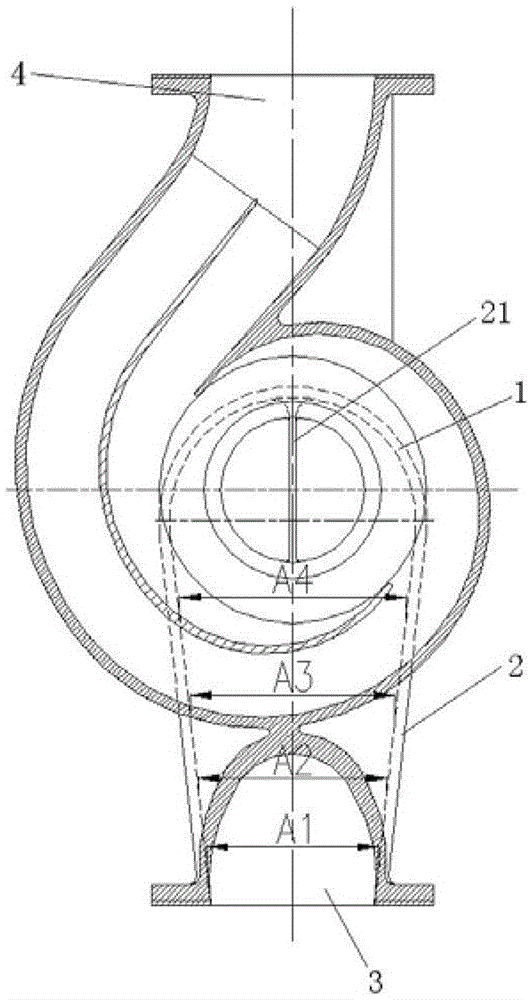

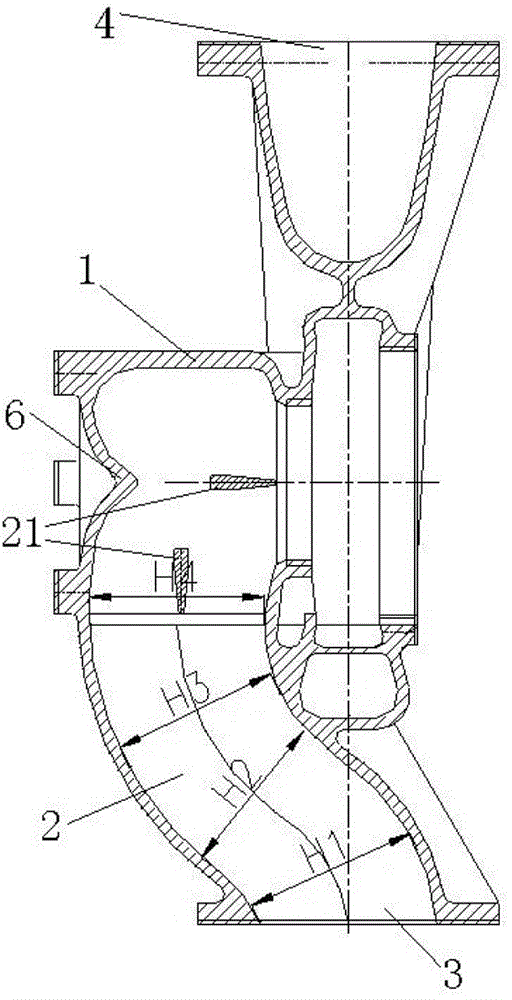

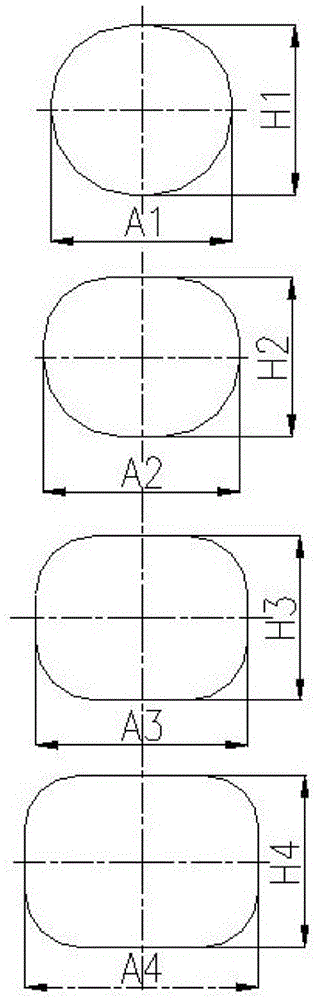

[0014] Such as Figures 1 to 3 The shown water inlet channel of a pump body includes a water absorption chamber, the water absorption chamber includes an annular body 1 and a flow channel part 2, the annular body 1 is eccentrically arranged, and a diversion cone 6 is arranged at the bottom of the annular body 1, and the inlet of the water absorption chamber The water inlet 3 is circular, and the cross section of the flow channel part 2 gradually shrinks from the annular body 1 to the water inlet 3, and the area gradually decreases.

[0015] A rib 21 is provided at the center of the flow channel part 2 to improve the stability of the flow.

[0016] The distance between the center of the ring body 1 and the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com