Sintering method with part of return mine being sintered without pelletization being pelletized

A sintering method and unmanufactured technology, applied in the field of iron ore powder sintering, can solve the problems of poor granulation effect, granulation damage, unfavorable sintering material layer permeability, etc. The effect of improving the granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

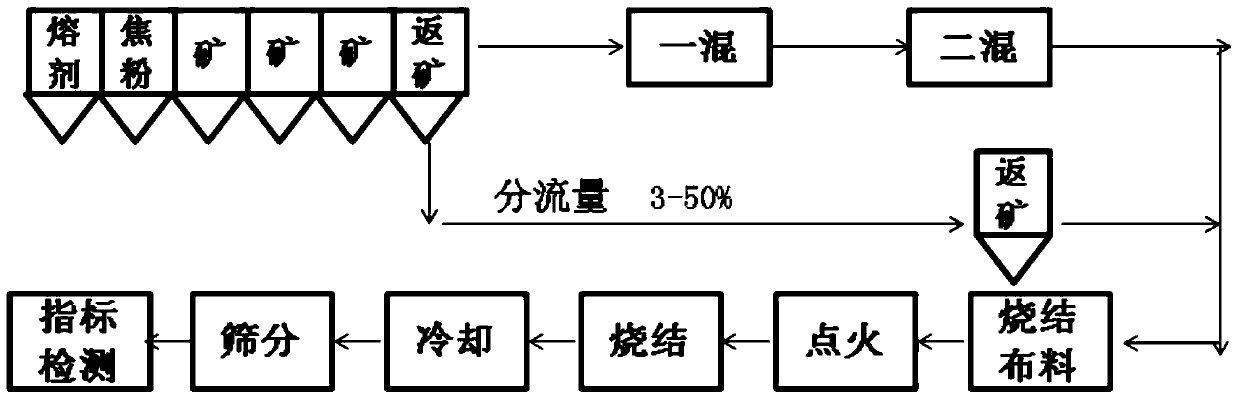

Method used

Image

Examples

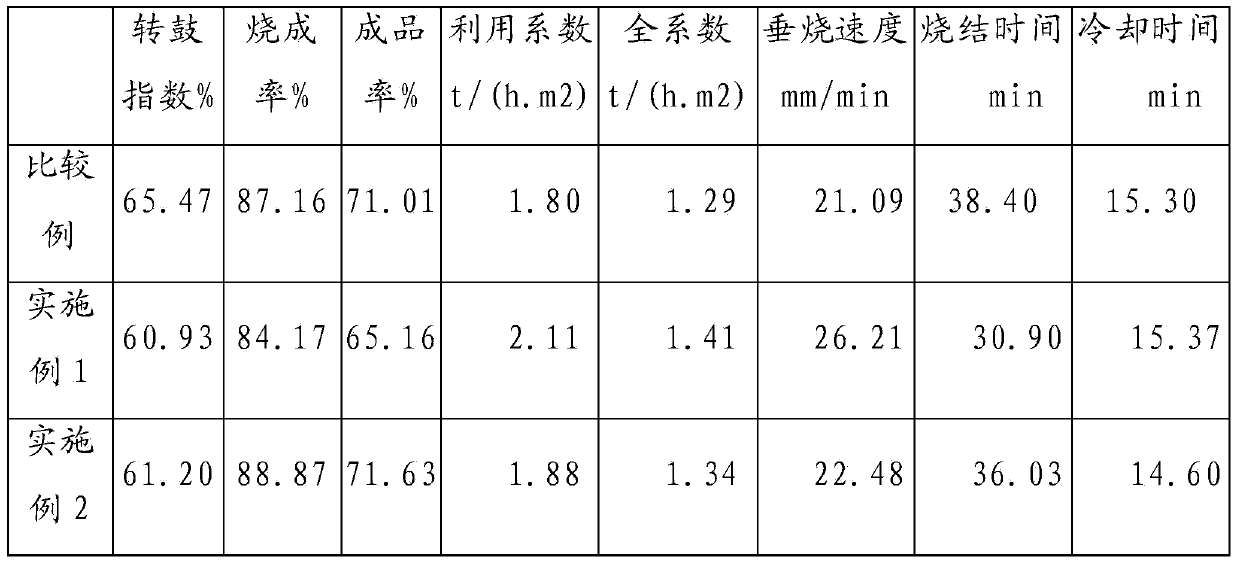

Embodiment 1

[0030] 1) Sintering raw material equipment, the sintering raw material includes: iron ore powder 53.6%, returned ore 36.3%, quicklime 2.1%, dolomite 2%, limestone 2.5%, coke powder 3.5%, see Table 1.

[0031] 2) Separation of returned ore: Among the sintering raw materials provided, 7.5% of the total mass of returned ore is taken out for use in subsequent processes. This returned ore is all blast furnace returned ore.

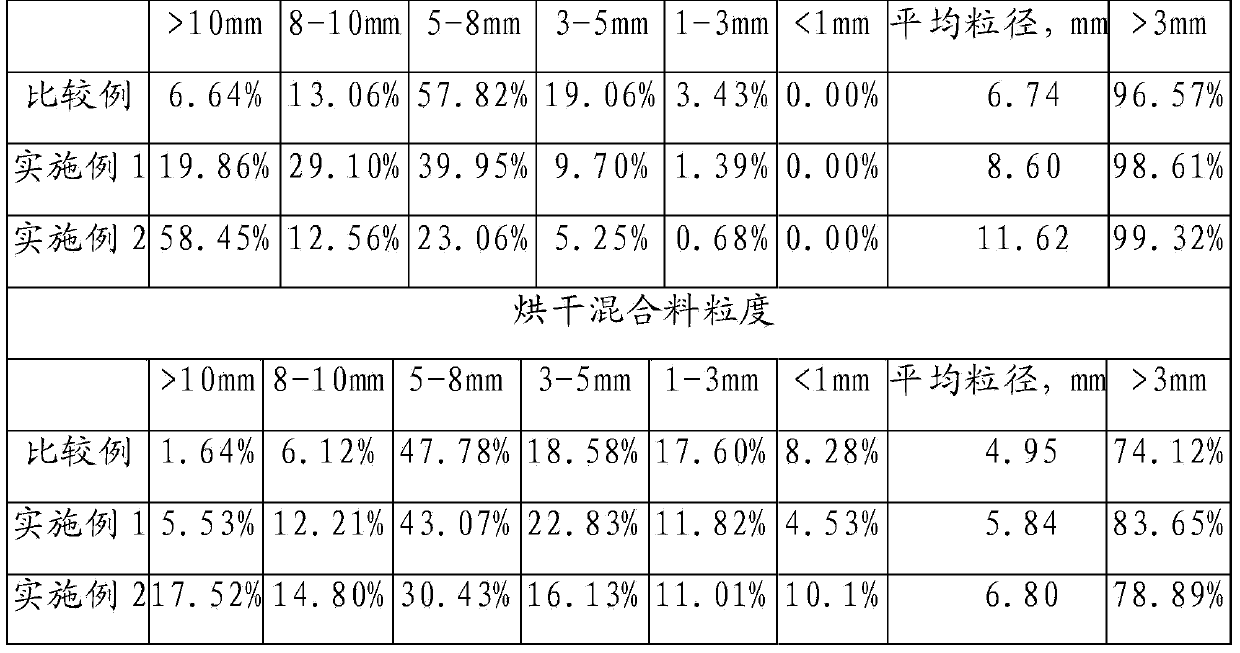

[0032] 3) Mixing: Transport all the remaining sintering raw materials to the primary cylinder mixer, add 6.0% of the total mass of the remaining sintering raw materials to wet the sintering raw materials, and mix the sintering raw materials with water evenly, and the particle size of the obtained mixture is The composition is shown in Table 2.

[0033] 4) Granulation: Transport the wetted and uniformly mixed sintered raw materials to the secondary cylinder mixer for remixing and granulation. The granulation time is 4 minutes; then add 7.5% of the pre-extracted ...

Embodiment 2

[0041] 1) Sintering raw material equipment, the sintering raw material includes: iron ore powder 53.6%, returned ore 36.3%, quicklime 2.1%, dolomite 2%, limestone 2.5%, coke powder 3.5%, see Table 1.

[0042] 2) Separation of returned ore: Among the sintering raw materials provided, 22% of the total mass of returned ore is taken out for use in subsequent processes. Among them, the composition of the returned ore taken out is 7.5% blast furnace returned ore and 14.5% sintered self-returning ore.

[0043] 3) Mixing: Transport all the remaining sintering raw materials to the primary cylinder mixer, add 6.5% of the total mass of the remaining sintering raw materials to wet the sintering raw materials, and mix the sintering raw materials with water evenly, and the particle size of the obtained mixture is The composition is shown in Table 2.

[0044] 4) Granulation: Transport the wetted and uniformly mixed sintered raw materials to the secondary cylinder mixer for remixing and gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com