Anti-locking saddle locking mechanism

A locking mechanism and anti-lock technology, applied in motor vehicles, tractor-trailer combination, transportation and packaging, etc., can solve the problems of traction pin locking and difficulty in removing and hanging, and achieve the goal of improving reliability and economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

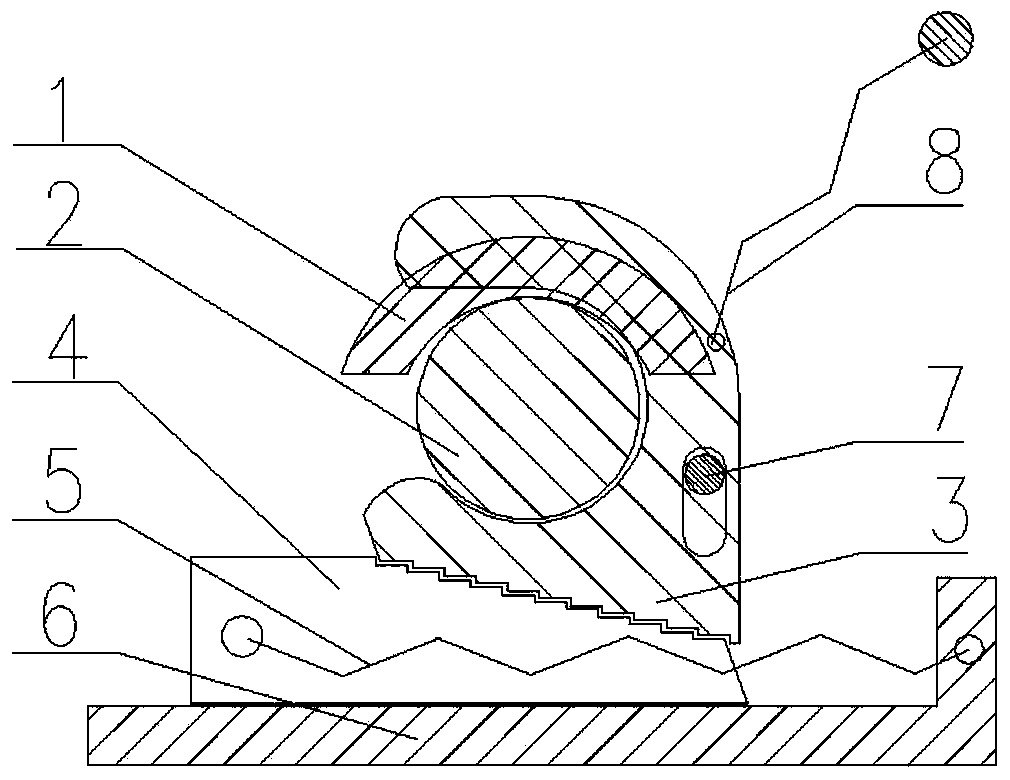

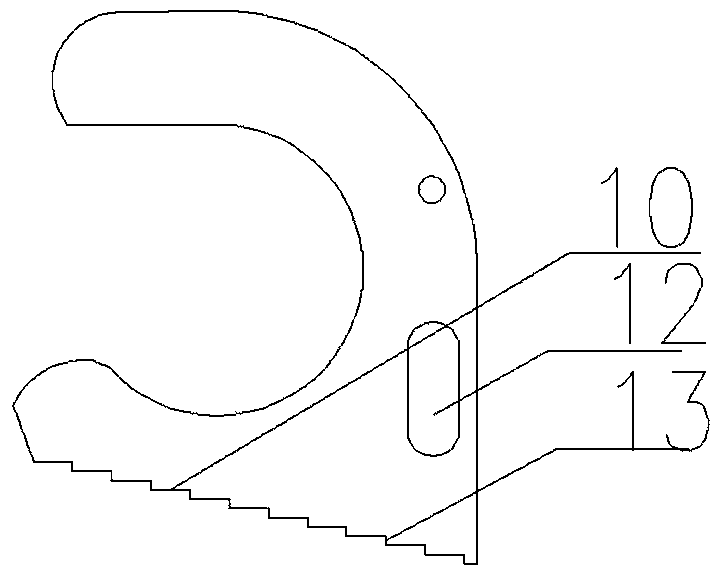

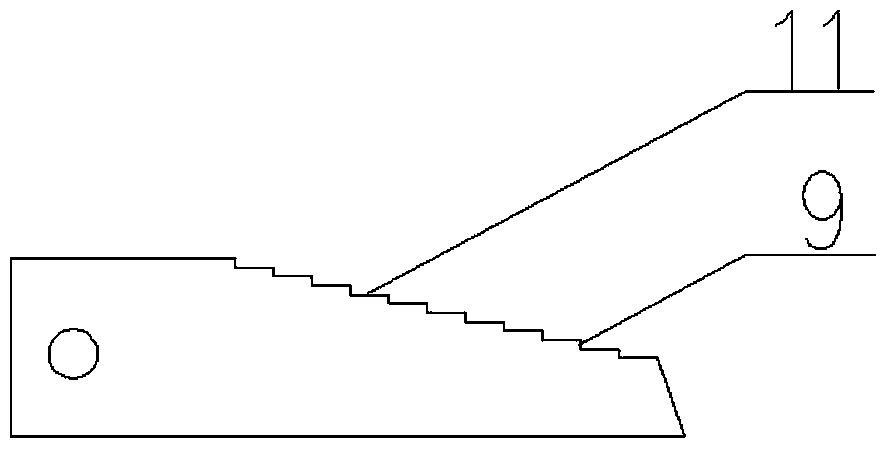

[0018] An anti-lock saddle locking mechanism, such as Figure 1-3 Shown, comprise lock hook 3, pin block 4, extension spring 5 and lock hook spring 8, described lock hook 3 is provided with the lock hook spring 8 that makes lock hook 3 rotate around pin shaft 7, and described pin block 4 is positioned at Between the lock hook 3 and the rear beam plate 6, the two ends of the extension spring 5 that pulls the pin block 4 to slide on the rear beam plate 6 are respectively connected to the rear beam plate 6 and the pin block 4, and the wedge-shaped surface of the lock hook 3 is stepped. , the wedge-shaped surface of the pin block 4 is stepped to match the wedge-shaped surface of the lock hook 3 .

[0019] The lock hook 3 includes a plurality of steps, the plane I10 of each step is perpendicular to the plane II13 , and the plane I10 is parallel to the rear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com