Flip box automatic production line and production method thereof

A technology of automatic production line and uncovering box, applied in the direction of carton/carton manufacturing machinery, paper/cardboard container, container, etc., can solve the problem that the product quality cannot reach a unified standard, the salary standard of ordinary operators is rising, and the product month cannot be met. Order requirements and other issues, to achieve the effect of simple and convenient control, improved efficiency, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

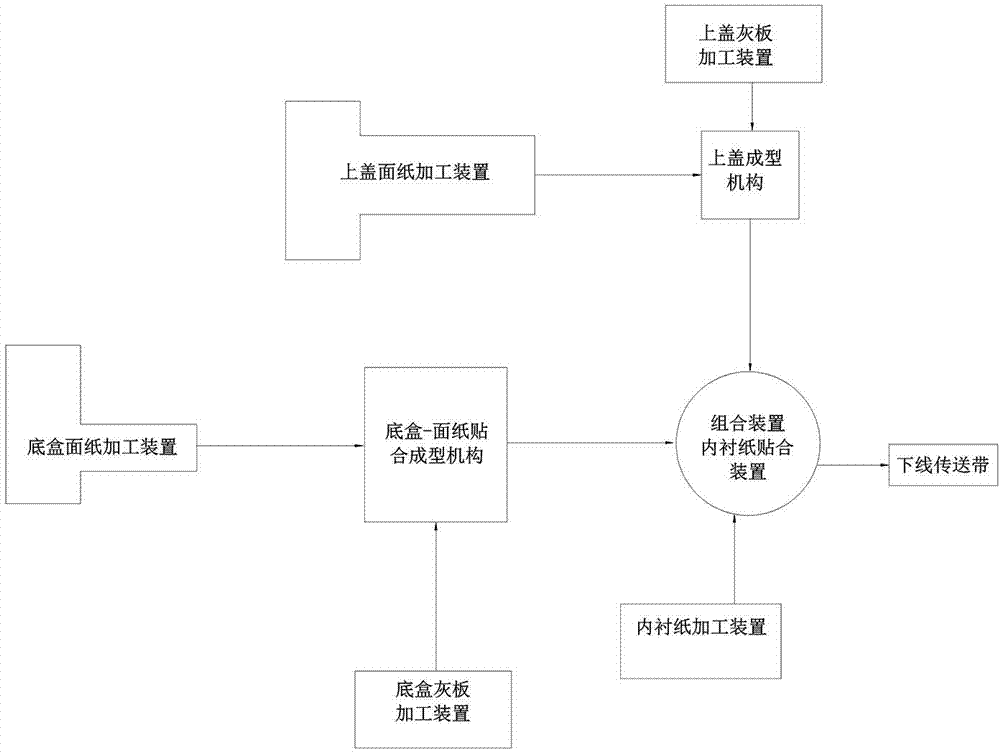

[0030] Embodiment: the overall structural block diagram of the automatic production line of the cover box of the present embodiment is as follows figure 1 As shown, the following modules are included:

[0031] The bottom box making module, including the bottom box face paper processing device and the bottom box gray board processing device connected to the input end of the bottom box-face paper laminating and forming mechanism, and the bottom box tape is connected to the output end of the bottom box-face paper laminating and forming mechanism conveying mechanism;

[0032] A cover making module, including a cover paper processing device and a cover gray board processing device that are jointly connected to the input end of the cover forming mechanism;

[0033] Upper cover-bottom box combination module, including combination device, lining paper laminating device and off-line conveyor belt;

[0034] The output ends of the bottom box making module and the lid making module are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com