Method for carrying out non-contact measurement on plane transformation by using low-dimensional nano material

A non-contact measurement, low-dimensional nanotechnology, applied in the direction of measuring devices, analyzing materials, using optical devices, etc., can solve the problems of difficult guarantee of repeatability, low preparation level, narrow applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

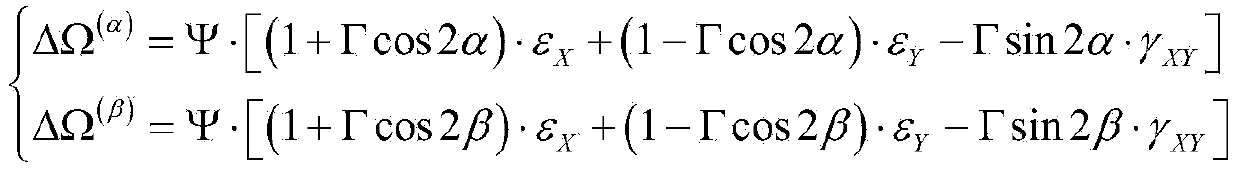

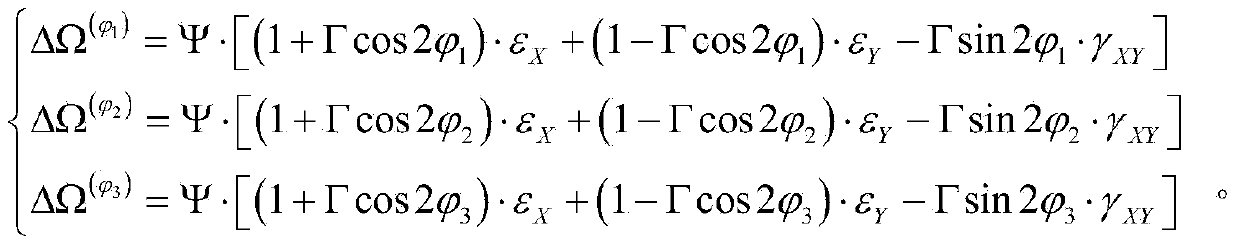

Method used

Image

Examples

Embodiment Construction

[0019] The method of the present invention will be further described below through specific embodiments. It should be noted that this embodiment is narrative rather than limiting, and does not limit the protection scope of the present invention.

[0020] In this example, "deformation analysis of carbon fiber reinforced epoxy resin strip specimen under three-point bending load" is taken as a specific implementation manner. The specific measurement steps are as follows:

[0021] (1) Sample preparation: the side surface of the carbon fiber reinforced epoxy resin strip specimen was mechanically polished and cleaned with acetone; single-walled carbon nanotubes with a purity of 60% (of which single-walled carbon nanotubes accounted for 60% by weight, Multi-walled carbon nanotubes accounted for 35%, nano-scale graphite particles and catalyst impurities accounted for 5%) mixed with liquid epoxy resin in a mass ratio of 1:99. After ultrasonic dispersion, the mixture was laminated on a carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com