Motor assembly for centrifugal fan

A technology for centrifugal fans and motors, which is applied to machines/engines, parts of pumping devices for elastic fluids, pump elements, etc., which can solve the problems of poor hydrodynamic performance of blades, inability to conduct concentrated air flow, and energy consumption of fans. Advanced problems, to achieve the effect of improved fluid mechanics performance, beautiful appearance, and reduced work energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

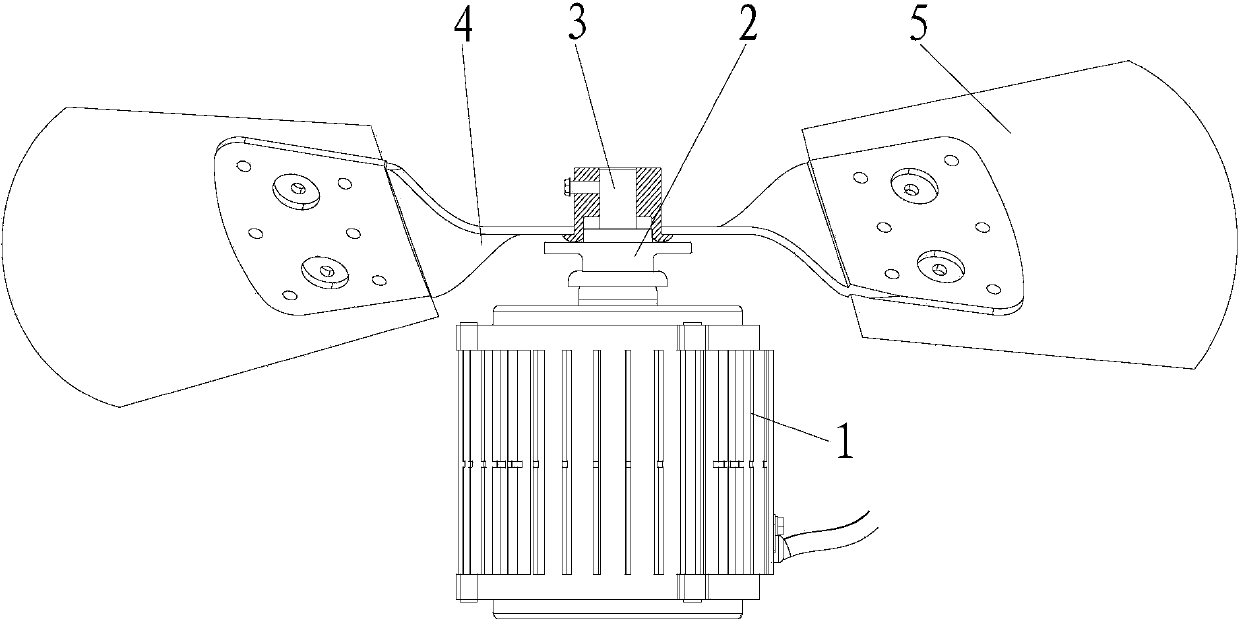

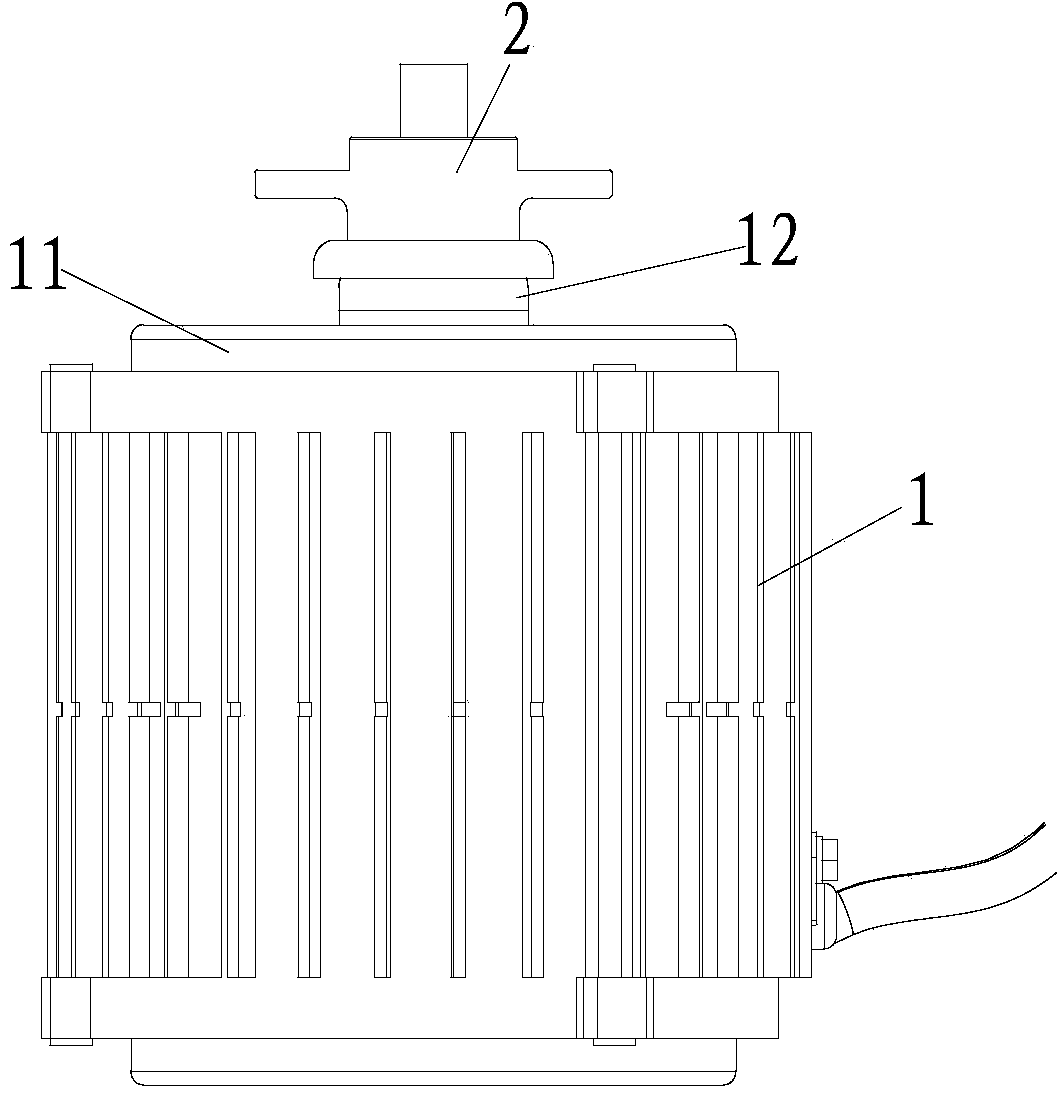

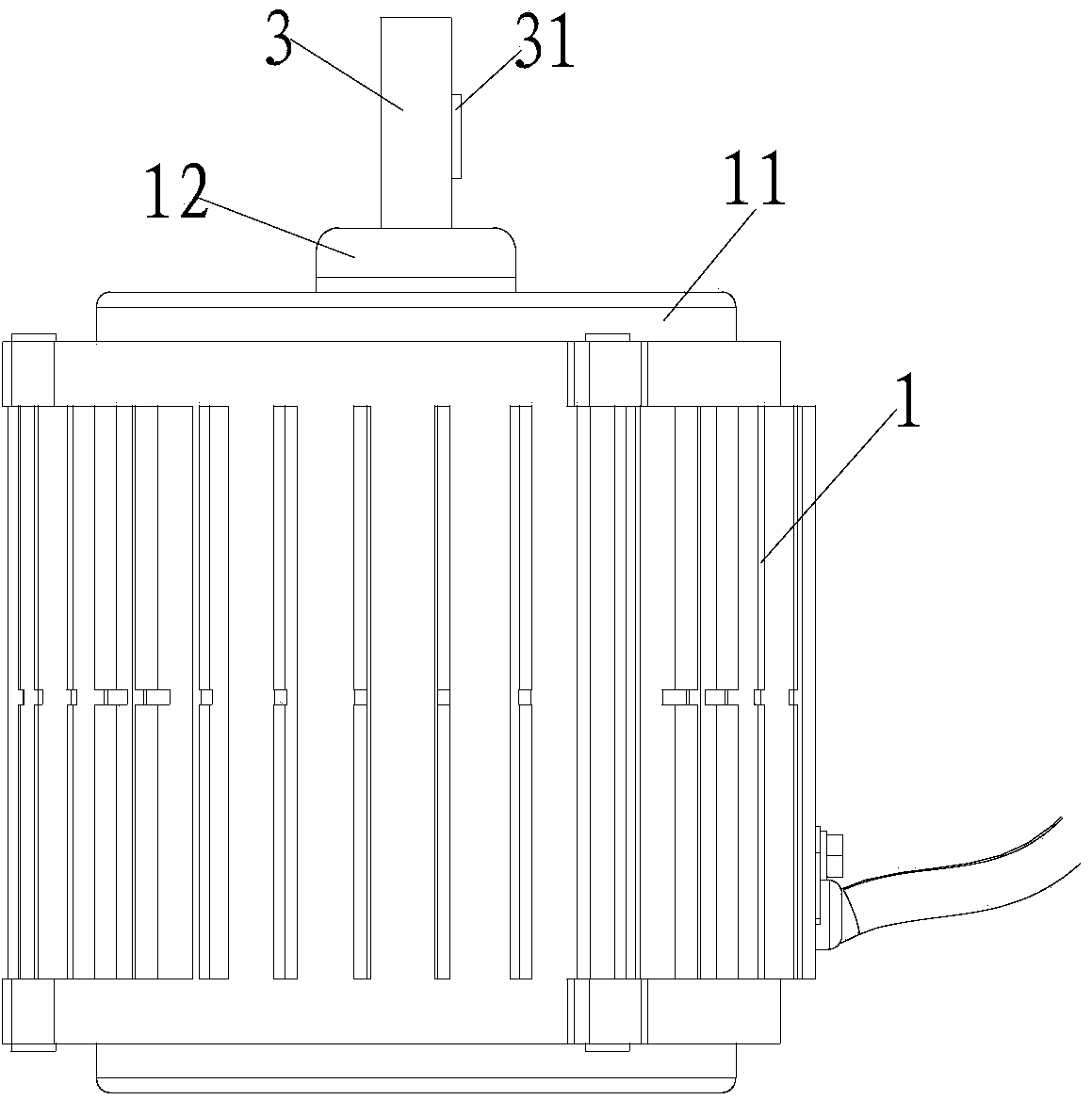

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , a motor assembly for a centrifugal fan in the present invention, comprising a motor 1, a waterproof shaft sleeve 2, a hub assembly 4 and an embossed blade 5, the motor 1 is provided with an end cover 11 and an output shaft 3, and the end cover 11 Cover the front end of the motor 1 through the output shaft 3, the end of the output shaft 3 is provided with a sealing sleeve 12, the waterproof sleeve 2 is installed on the output shaft 3, and the waterproof sleeve 2 includes a mounting sleeve 21 and a waterproof disk 22 , the waterproof disk 22 is covered on the sealing sleeve 12, the hub assembly 4 is installed on the waterproof sleeve 2, the hub assembly 4 includes a hub 41 and a riveted sleeve 42, and the hub 41 is provided with several installation plate 411, the embossing blade 5 is installed on the mounting plate 411, the output shaft 3 is provided with a block-shaped protrusion structure 31, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com