Stacking mold with ejecting rods

A technology of ejector and mold, applied in the field of stacking molds, can solve the problems of scratching of ejector, impact on shell parts, unqualified structure, etc., and achieve the effect of convenient use and soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be further described in detail below.

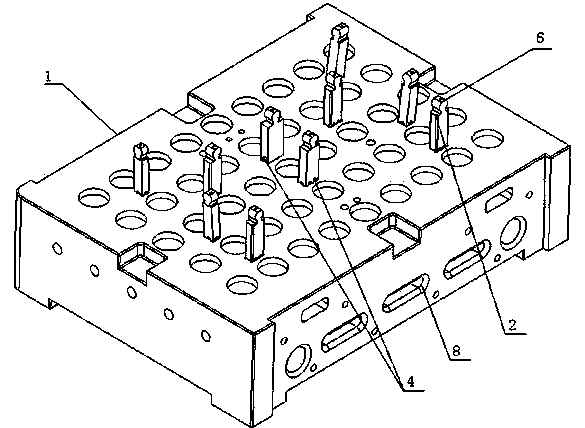

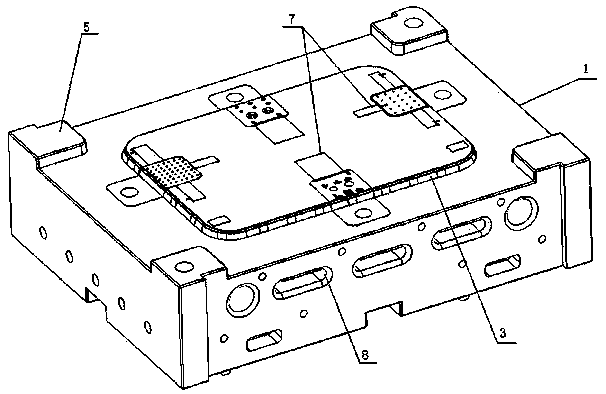

[0016] Such as figure 1 with figure 2 As shown, a stacked mold with ejector pins of the present invention includes: a body 1, a cavity 3 located at the top of the body, and several ejector pins 2 located at the bottom of the body. The ejector pins 2 protrude from the bottom of the body 1, and the ejector pins 2 is set on the bottom of the body 1 through the return pin 4, and the ejector pin hole 7 corresponding to the position of the ejector pin 2 is provided on the cavity 3. The main body 1 is a cuboid structure, and four corners of the top of the main body 1 are respectively provided with a pillar 5 , and the height of the pillar 5 is less than the length of the ejector rod 2 . Several ejector pins 2 are arranged on the bottom of the body 1 in axisymmetric manner, two ejector pins 2 are located on the axis of axisymmetrical axis, and four ejector pins 2 are arranged at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com