Dried figwort and preparation method thereof

A technology of scrophularia and drying, which is applied in pharmaceutical formulations, medical preparations containing active ingredients, and plant raw materials, etc., can solve the problems of poor process linearity, long drying time, and high drying temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Comparative example

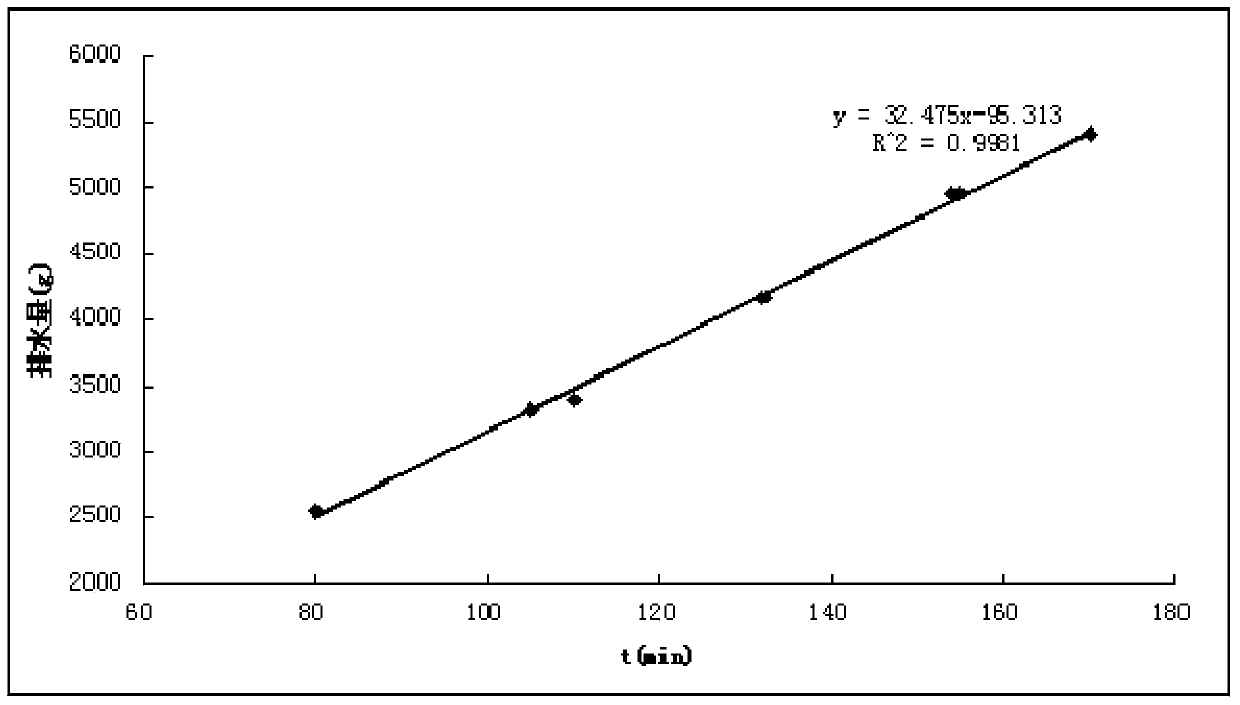

[0018] Sichuan Scrophulariae 5715g, 2000W microwave vacuum drying for 90min, drainage 2755g, drainage rate 48.2%; dried to 110min, cumulative drainage 3395g, cumulative drainage rate 59.41%, slightly carbonized; put into blast drying box to constant weight. The dry weight is 1355g, and the cumulative drainage rate is 76.3%.

Embodiment 2

[0019] Embodiment 2 Comparative example

[0020] Sichuan Scrophulariae 5090g, 2000W microwave vacuum drying for 80min, drainage 2550g, drainage rate 50.1%; 1500W microwave vacuum drying for 30min, drainage 785g, cumulative drainage rate 65.5%; 1000W microwave vacuum drying for 20min, drainage 290g, cumulative drainage rate 71.2%; Put into a blast drying oven to constant weight. The dry weight is 1160g, and the cumulative drainage rate is 77.0%.

Embodiment 3

[0021] Example 3 Comparative example

[0022] Sichuan Scrophulariae 10000g, 2000W microwave vacuum drying for 170min, drainage 5405g, drainage rate 54.05%; 1500W microwave vacuum drying for 45min, drainage 1175g, cumulative drainage rate 65.8%; 1000W microwave vacuum drying for 40min, drainage 660g, cumulative drainage rate 72.4%, Slightly carbonized; put into blast drying oven to constant weight. The dry weight is 2305g, and the cumulative drainage rate is 76.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com