Deep groove carrier roller set

A technology of idlers and idlers, applied in the direction of rollers, conveyors, conveyor objects, etc., can solve the problems of easy bending and wear of belts, reduced transportation volume, etc., to ensure transportation volume, increase groove depth, The effect of avoiding bending damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

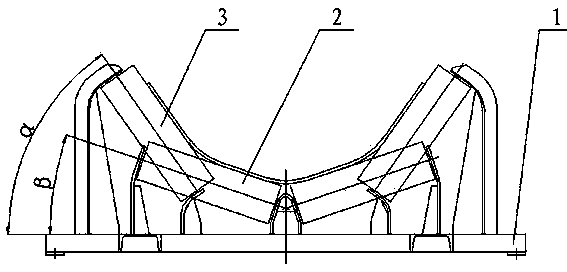

[0011] Such as figure 1 , the middle idler 2 and the side idler 3 are installed on the crossbeam 1, and are fixedly installed by respective idler brackets and ribs. Among them, the angle between the side idler and the beam is α, which is 65°, and the angle between the middle idler and the beam is β, which is 20°. Such as figure 2 , The distance L between the front and back of the middle idler and the side idler is 1.2 times the diameter of the idler.

Embodiment 2

[0013] Such as figure 1 , the middle idler 2 and the side idler 3 are installed on the crossbeam 1, and are fixedly installed by respective idler brackets and ribs. Among them, the angle between the side idler and the beam is α, which is 65°, and the angle between the middle idler and the beam is β, which is 25°. Such as figure 2 , The distance L between the front and back of the middle idler and the side idler is 1.5 times the diameter of the idler.

Embodiment 3

[0015] Such as figure 1 , the middle idler 2 and the side idler 3 are installed on the crossbeam 1, and are fixedly installed by respective idler brackets and ribs. Among them, the angle between the side idler and the beam is α, which is 65°, and the angle between the middle idler and the beam is β, which is 30°. Such as figure 2 , The distance L between the front and back of the middle idler and the side idler is 1.8 times the diameter of the idler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com